- You cannot add "Ender 3 Motherboard" to the cart because the product is out of stock.

CR-10 & Tevo Tarantula Direct Drive Upgrade Kit – v1.2

Original price was: $44.90.$34.95Current price is: $34.95.

- Easy to Install

- No Modification Required

- Better Routing of Filament

Out of stock

Description

This is a new and improved version of our previous Creality CR-10 Direct Drive Kit

Creality CR-10 Direct Drive

Creality CR-10 Direct Drive upgrade kit:

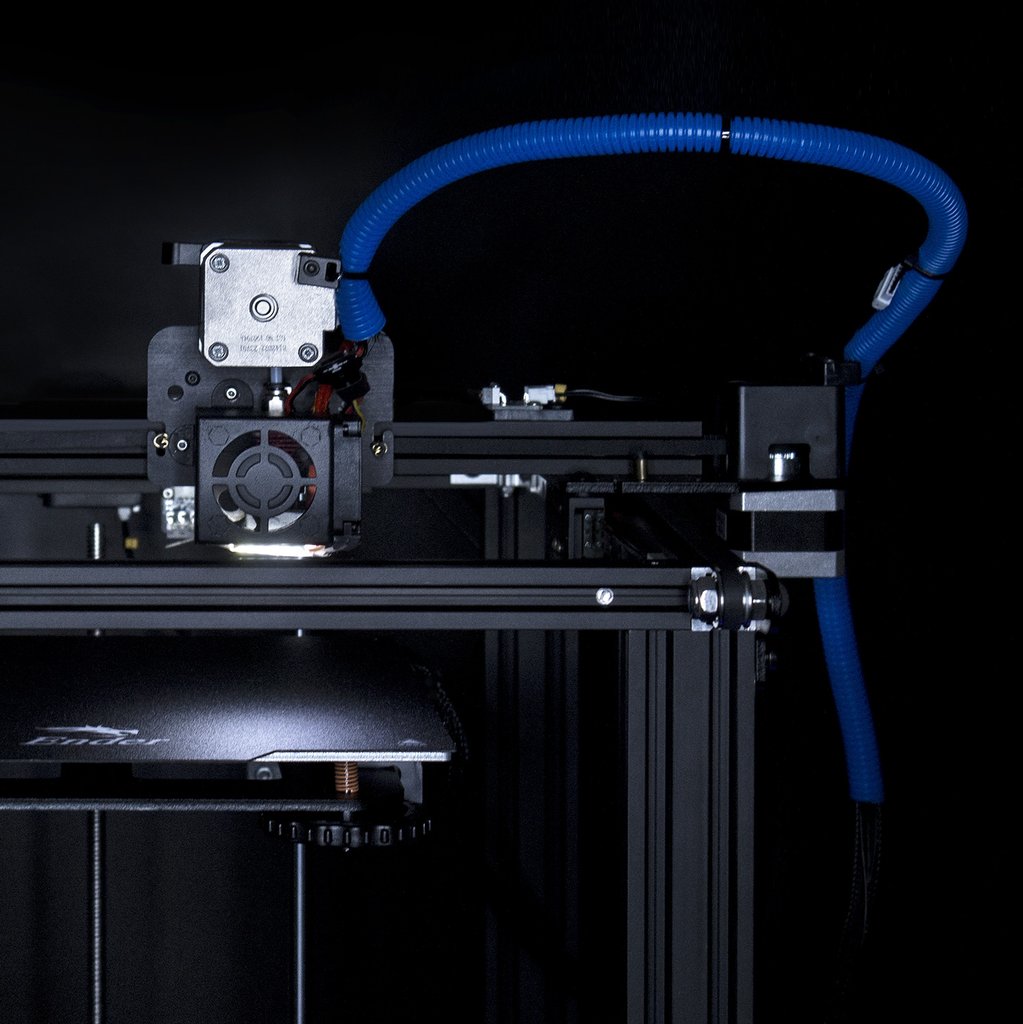

Increase print quality, simplify retractions and filament changes, and print any material with ease with the MDD v1.2, the easiest direct drive conversion kit available for your CR-10 3D printer.

Lighter than a Titan Aero or Bondtech, the MDD takes just 20-30 minutes to install– with no firmware changes, no printable volume loss, and no cutting or splicing required.

The MDD (or ”Modular Direct Drive”) easily converts your stock CR-10 into a true direct drive 3D printer. While the MDD is compatible with many different hot end and extruder combinations, it was specifically engineered to convert your stock components into a powerful direct drive system with no additional hardware or wiring needed, making it the simplest and most flexible direct drive system.

Ender 3 Version

There is also a version of this that will work on the Creality CR-10 and Tevo Tornado available here.

Ender 5 Version

If you have an Ender 5, you can purchase a kit designed specifically for the Creality Ender 5 here.

HIGHLIGHTS

- Increase print quality and fix retraction issues

- Does not require dual lead screws

- Print higher temperature and flexible materials

- Reduce retractions and ooze control

- Easier filament changes

- No firmware or bootloader flashing

- No cutting or splicing wires

- Works with stock extruder and hot end

- Compatible with many printable mods

DIRECT DRIVE VS. BOWDEN TUBE EXTRUDERS

Bowden style extrusion systems like those found on Creality printers rely on long PTFE tubes to feed filament to the hot end, and as such are more prone to extrusion issues. While Bowden setups generally allow for lighter print head weights, mounting the extruder separately from the hot end comes at the expense of less precise retraction control and filament changes.

By contrast, direct drive extruders eliminate most common extrusion problems by mounting the extruder and hot end very closely together, removing the need for the PTFE tubing in between and drastically shortening and simplifying the filament path. While this approach can significantly improve extrusion and retraction, and allow for easier printing of difficult materials like flexible filaments, it also increases the weight on the hot end carriage, necessitating reduced print speeds if made too heavy.

MDD – A BETTER DIRECT DRIVE OPTION

Weighing in at 479g when installed with a full-sized stepper, the MDD is light enough to print fast, while solving many of the extrusion problems inherent to Bowden extruder systems. And because it entirely replaces the hot end carriage, it provides a vastly more rigid mounting platform for the extruder and hot end compared with printed direct drive mounts, which are more prone to vibration and ringing when printing at higher speeds.

Want to install this on a larger format machine than the CR-10 and larger?

All you need is one or more motor extension cables.

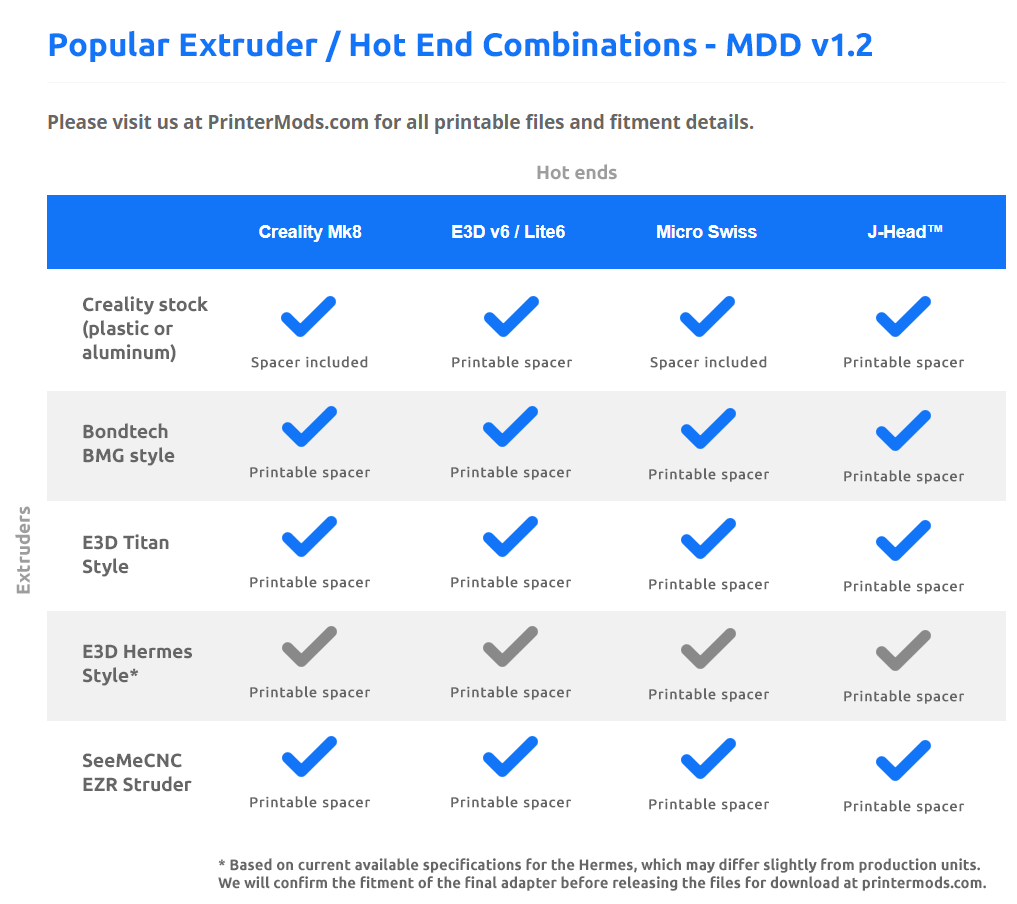

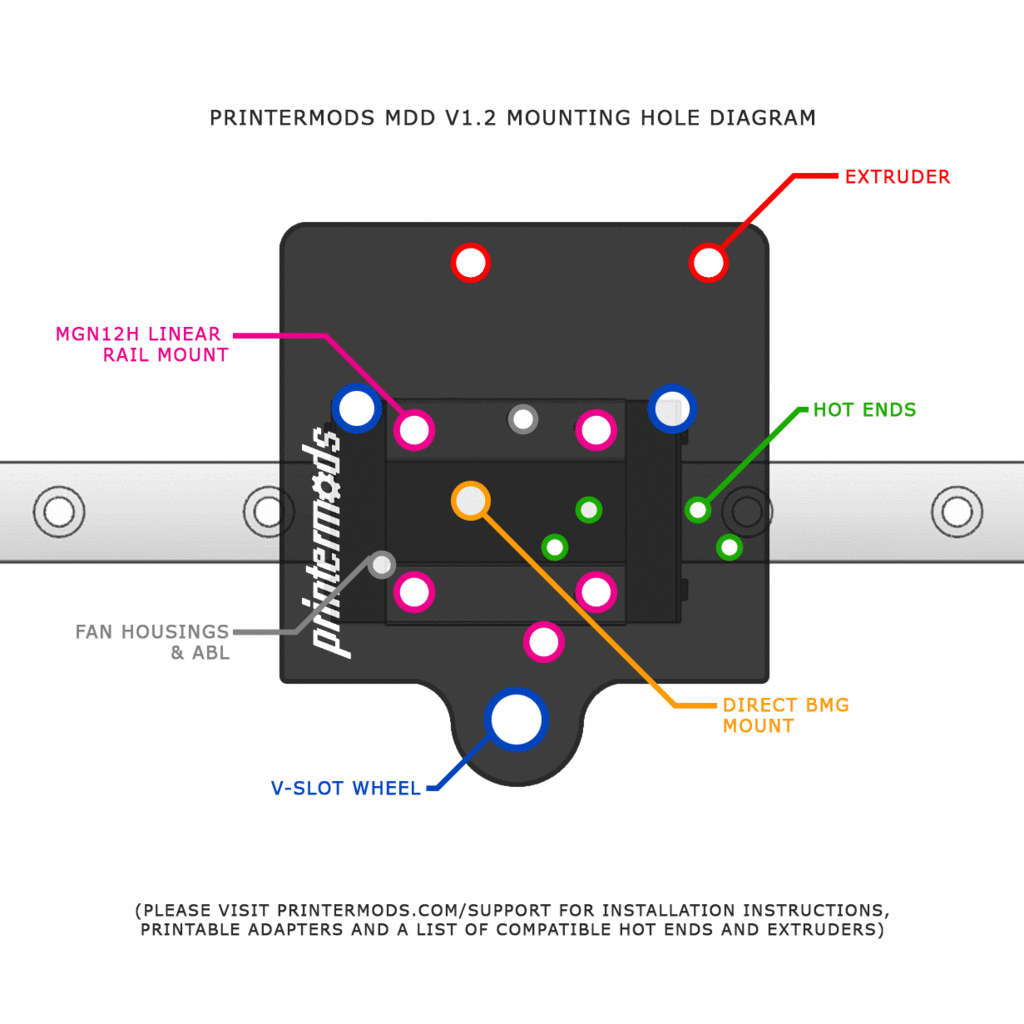

Hot end / Extruder Compatibility

| Creality Mk8 | E3D v6 / Lite6 | Micro Swiss | J-Head | |

|---|---|---|---|---|

| Creality Mk10 (factory or aluminum) | Spacer included | STL(s) needed: V6 / J adapter | Spacer included | STL(s) needed: V6 / J adapter |

| Bondtech BMG | STL(s) needed: BMG spacer, Mk8 J adapter, Mk8 fan duct | STL(s) needed: BMG spacer | STL(s) needed: BMG spacer, Mk8 J adapter, Mk8 fan duct | STL(s) needed: BMG spacer |

| E3D Titan | STL(s) needed: Titan 6mm spacer, Mk8 J adapter, Mk8 fan duct | STL(s) needed: Titan 6mm spacer | STL(s) needed: Titan 6mm spacer, Mk8 J adapter, Mk8 fan duct | STL(s) needed: Titan 6mm spacer |

| SeeMeCNC EZR Struder™ | STL(s) needed: EZR Struder spacer | STL(s) needed: EZR Struder spacer, V6 / J adapter | STL(s) needed: EZR Struder spacer | STL(s) needed: EZR Struder spacer, V6 / J adapter |

Technical Specs

- CNC machined 6063 aluminum construction

- Injection molded fittings – no 3D printed parts*

- Printed or customized parts may be required to mount up certain combinations of non-factory or 3D printed components.

- Weighs under 500g fully installed (including fan shroud, wiring, hardware)

- Wire harness extender included

- High-temp PTFE tube rated for 260ºC+

- Simple 20 minute installation (instructions provided)

FAQ

Q: Is it too heavy? Do I need a dual Z lead screw?

A: No, a dual lead screw setup is not needed for the MDD, even when using a full-sized Creality stepper motor. Just a properly aligned X gantry (see this guide for more information: https://www.youtube.com/watch?v=4bFYH0X3qjk)

Our tests have demonstrated that the increased effector mass on the X axis is not heavy enough to cause significant unwanted deflection or drop, even higher than average travel speeds. This is partly due to the rigid coupling and alignment of the stepper motor with the MDD’s solid carriage plate, which restricts unwanted movements and vibrations, and effectively translates those forces to the rollers, which are more than strong enough to bear the load without deforming.

Q: Which Creality CR models is it compatible with?

A: The MDD will fit all CR models EXCEPT the CR-10S PRO.

For the Ender 5 version, click here.

For the Ender 3 version, click here.

Q: What hot ends and extruders does the MDD work with?

A: Many, though we recommend using it with the stock Creality hot end and extruder combination. Other supported components include extruders like the Bondtech BMG, E3D Titan and EZR Struder, as well as hot ends like the E3D V6 and Micro-Swiss, with more compatibility coming soon.

Q: What slicer settings do I need to change?

A: Slicer settings can vary based on machine, filament, etc. However, you should expect to significantly reduce your slicer retraction settings (we recommend starting around 1.0mm at 30mm/s and tuning from there). You will also need to disable ooze control methods like coasting, wipe, etc.

Q: Where does this product ship from?

A: We manufacture and produce our kits in the USA. All MDD kits purchased from Fargo 3D Printing ship from Fargo, ND in the USA.

Q: Does this upgrade have a mounting point for an auto-leveling system like the BL Touch?

A: YES.

More Resources

Additional information

| Weight | 0.3 lbs |

|---|---|

| Dimensions | 6 × 4 × 1 in |

| 3D Printer Compatibility | CR-10 Mini, Creality CR-10s, Creality CR-10s4, Creality CR-10s5, Creality CR-10, Tevo Tarantula |