When MakerBot invited us to visit their Brooklyn, New York Headquarters this week, we jumped at the chance.

We got to work with the new MakerBot Replicator 5th Gen, see the MakerBot Replicator Mini, and finally put a face to many of the great folks we’ve communicated with at MakerBot.

Our flight left Fargo at 7:30 in the morning, which meant we had to be to the airport at 6. I’m not a morning person, and I think this picture of me sitting in the airport conveys that message loud and clear.

The weather in Fargo was anything but sunny, so it was refreshing to be treated with this view once we hit cruising altitude.

We arrived at our hotel in Brooklyn, played a quick game a peek-a-boo (hi Jake!) and then spent some time exploring downtown Brooklyn.

After a good night’s sleep we paid our visit to MakerBot, located just 3 blocks away from our hotel. Can you tell we were a bit excited? We were the first ones there, they hadn’t even unlocked the doors yet!

This is a quick look at the lounge area of the MakerBot offices. They were pretty secretive (understandably so) so we don’t have a ton of behind-the-scene shots, but this gives a taste of what it’s like to work there every day.

The hands-on-training was very informative and we had the opportunity to talk to and learn from other MakerBot resellers about what they’ve been finding out about their customers.

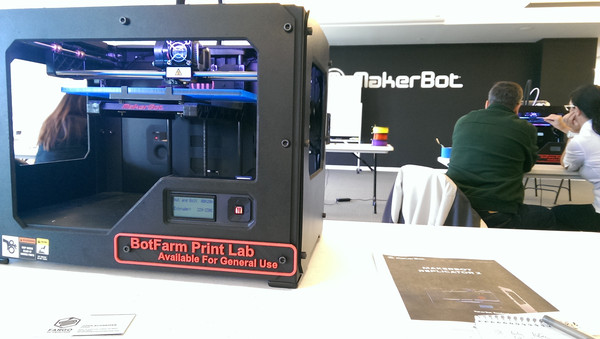

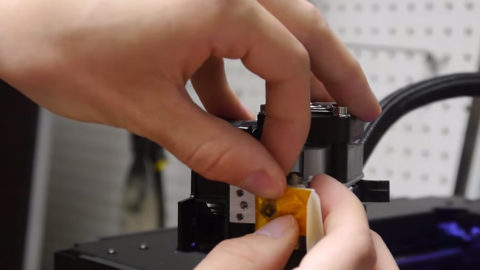

We had some hands-on time with the new 5th Gen MakerBot Replicator and even got to see the MakerBot Replicator Mini. The 5th Gen has some cool features like a built-in camera and assisted leveling. The leveling take a little more time to do automatically, but no longer do you need to slide a piece of paper under the nozzle to see if the height is set correctly. It does that on its own.

It takes measurement by pressing the nozzle onto the build plate (the nozzle acts as a plunger) in two places. Then to level the bed, it moves the nozzle to another location on the bed. If the bed isn’t level, it will tell you on screen which direction to twist the knob under the bed (there are two). Once it’s in the right place, a light on the extruder will come on. Very very useful for setting the bed correctly every time.

We were also able to check out MakerBot’s BotFarm (no pictures, sorry!) which is essentially a room with over 100 printers cranking away on various projects.

The next day Jake and I went to MakerBot’s retail store in Manhattan. Again, we’re a bit excited, can you tell?

On the inside were multiple Replicator 2, 2X, and 5th Gen printers working away on their prints. Customers were coming in non-stop, purchasing filament, getting custom prints made, and just coming in to satisfy their curiosity. There was a camera crew there doing a story on the 3D scanner that was set up. We were told that camera crews are a frequent occurrence as the public is very interested in 3D printing.

We stuck around the MakerBot Store for an hour or two, then ran about the city doing some of the normal touristy things. Later that night, we headed to La Guardia airport and caught this great photo of an evening skyline.

It was a great trip, and we can’t wait to go back and visit MakerBot again!

You are a very clever individual!

I¦ve been exploring for a bit for any high-quality articles or blog posts in this kind of area . Exploring in Yahoo I finally stumbled upon this site. Studying this info So i¦m happy to convey that I have a very excellent uncanny feeling I found out just what I needed. I so much without a doubt will make sure to do not fail to remember this web site and give it a look regularly.

I simply had to appreciate you once again. I am not sure what I could possibly have gone through in the absence of these creative ideas discussed by you about such a topic. It had become a frightening circumstance in my opinion, however , taking a look at the very well-written form you managed it made me to weep with joy. I am just happy for this help and thus wish you find out what a great job you were doing teaching the mediocre ones via a blog. I’m certain you’ve never come across any of us.

Thanks for another informative blog. Where else may just I am getting that kind of information written in such an ideal approach? I have a challenge that I am simply now working on, and I’ve been at the glance out for such info.

hey there and thank you to your info – I have certainly picked up something new from proper here. I did then again expertise several technical points the usage of this website, since I skilled to reload the website lots of instances prior to I may get it to load correctly. I had been puzzling over in case your hosting is OK? No longer that I’m complaining, however sluggish loading circumstances times will sometimes affect your placement in google and can damage your quality ranking if ads and ***********|advertising|advertising|advertising and *********** with Adwords. Anyway I am including this RSS to my e-mail and can glance out for much extra of your respective exciting content. Make sure you replace this again soon..

Its superb as your other content : D, thankyou for putting up.

Hi would you mind sharing which blog platform you’re using? I’m looking to start my own blog in the near future but I’m having a tough time choosing between BlogEngine/Wordpress/B2evolution and Drupal. The reason I ask is because your design and style seems different then most blogs and I’m looking for something unique. P.S My apologies for getting off-topic but I had to ask!

I’m now not positive the place you are getting your info, but great topic. I needs to spend a while studying more or working out more. Thanks for fantastic info I was in search of this info for my mission.

It¦s really a nice and useful piece of info. I am satisfied that you shared this useful info with us. Please stay us up to date like this. Thank you for sharing.

I have been browsing on-line greater than 3 hours lately, but I never found any interesting article like yours. It is lovely price enough for me. Personally, if all webmasters and bloggers made excellent content material as you did, the internet will probably be much more helpful than ever before.

That is really interesting, You’re an excessively professional blogger. I’ve joined your feed and sit up for in the hunt for more of your excellent post. Also, I’ve shared your web site in my social networks!

Good write-up, I?¦m normal visitor of one?¦s blog, maintain up the excellent operate, and It is going to be a regular visitor for a long time.

I precisely desired to thank you so much yet again. I am not sure what I could possibly have tried in the absence of the tips and hints shared by you on such a concern. It previously was a troublesome crisis in my circumstances, but viewing the very skilled way you managed that made me to leap with gladness. Now i am thankful for this support and thus sincerely hope you really know what an amazing job you’re getting into teaching others thru your webblog. I am sure you’ve never come across any of us.

Thank you for sharing with us, I believe this website really stands out : D.

Some truly nice stuff on this web site, I like it.

You have observed very interesting details ! ps nice website .

Well I sincerely enjoyed reading it. This article procured by you is very helpful for good planning.

Would love to incessantly get updated outstanding website! .

I very thankful to find this website on bing, just what I was searching for : D besides saved to fav.

You made some good points there. I did a search on the topic and found most individuals will go along with with your site.

I believe this web site has got some really fantastic info for everyone : D.

Great line up. We will be linking to this great article on our site. Keep up the good writing.

I must point out my gratitude for your kindness giving support to those who require assistance with this one matter. Your very own dedication to getting the message all around ended up being really beneficial and have all the time empowered girls much like me to arrive at their pursuits. Your amazing helpful guideline means this much to me and much more to my fellow workers. Thank you; from everyone of us.

There are actually loads of details like that to take into consideration. That could be a great level to bring up. I provide the thoughts above as common inspiration but clearly there are questions like the one you deliver up the place crucial thing might be working in trustworthy good faith. I don?t know if greatest practices have emerged round things like that, however I’m certain that your job is clearly recognized as a fair game. Each girls and boys feel the influence of only a second’s pleasure, for the rest of their lives.

This blog is definitely rather handy since I’m at the moment creating an internet floral website – although I am only starting out therefore it’s really fairly small, nothing like this site. Can link to a few of the posts here as they are quite. Thanks much. Zoey Olsen

I went over this site and I conceive you have a lot of great info, saved to bookmarks (:.

I enjoy the efforts you have put in this, thanks for all the great content.

I was very pleased to find this web-site.I wanted to thanks for your time for this wonderful read!! I definitely enjoying every little bit of it and I have you bookmarked to check out new stuff you blog post.

That is the appropriate blog for anybody who wants to seek out out about this topic. You understand a lot its virtually laborious to argue with you (not that I truly would need…HaHa). You definitely put a brand new spin on a topic thats been written about for years. Nice stuff, simply great!

I see something truly interesting about your site so I saved to my bookmarks.

Can I just say what a relief to find someone who actually knows what theyre talking about on the internet. You definitely know how to bring an issue to light and make it important. More people need to read this and understand this side of the story. I cant believe youre not more popular because you definitely have the gift.

Wow! Thank you! I constantly wanted to write on my website something like that. Can I take a portion of your post to my blog?

Thanks for helping out, superb info .

I conceive you have observed some very interesting details , thankyou for the post.

I will immediately grab your rss feed as I can not find your email subscription link or e-newsletter service. Do you have any? Please let me know in order that I could subscribe. Thanks.

hi!,I like your writing very a lot! share we keep up a correspondence more approximately your article on AOL? I need an expert on this space to unravel my problem. Maybe that is you! Taking a look forward to look you.

I am continuously searching online for ideas that can aid me. Thx!

Whats Going down i am new to this, I stumbled upon this I’ve discovered It absolutely useful and it has helped me out loads. I’m hoping to contribute & help different users like its aided me. Great job.

I got what you mean , appreciate it for posting.Woh I am glad to find this website through google. “Those who corrupt the public mind are just as evil as those who steal from the public.” by Theodor Wiesengrund Adorno.

Dead composed content material, Really enjoyed reading through.

F*ckin¦ awesome issues here. I am very happy to see your article. Thank you a lot and i’m looking ahead to touch you. Will you please drop me a mail?

I haven’t checked in here for some time since I thought it was getting boring, but the last several posts are great quality so I guess I will add you back to my daily bloglist. You deserve it my friend 🙂

I am impressed with this website , rattling I am a big fan .

Enjoyed reading this, very good stuff, thanks. “Be not careless in deeds, nor confused in words, nor rambling in thought.” by Marcus Aurelius Antoninus.

Glad to be one of several visitors on this awful website : D.

I do not even know how I ended up here, but I thought this post was good. I do not know who you are but definitely you’re going to a famous blogger if you are not already 😉 Cheers!

Utterly composed content material, appreciate it for information .

you are really a good webmaster. The web site loading speed is incredible. It seems that you’re doing any unique trick. In addition, The contents are masterpiece. you’ve done a magnificent job on this topic!

Currently it appears like WordPress is the best blogging platform out there right now. (from what I’ve read) Is that what you’re using on your blog?

This website is my breathing in, real superb design and perfect articles.

Utterly composed subject material, thankyou for information .

Some genuinely excellent posts on this internet site, appreciate it for contribution.

I was suggested this web site by means of my cousin. I’m not positive whether or not this put up is written by means of him as no one else know such distinctive about my trouble. You are wonderful! Thanks!

I have learn some excellent stuff here. Definitely price bookmarking for revisiting. I wonder how much attempt you set to create the sort of excellent informative website.

Very interesting topic, regards for putting up.

Hi there! I just wanted to ask if you ever have any problems with hackers? My last blog (wordpress) was hacked and I ended up losing several weeks of hard work due to no data backup. Do you have any solutions to prevent hackers?

Wohh precisely what I was looking for, thanks for putting up.

I am not real excellent with English but I line up this real easy to interpret.

magnificent points altogether, you simply received a new reader. What could you suggest in regards to your publish that you simply made a few days ago? Any positive?

Great wordpress blog here.. It’s hard to find quality writing like yours these days. I really appreciate people like you! take care

You have observed very interesting details ! ps decent website .

At this time it appears like Movable Type is the top blogging platform out there right now. (from what I’ve read) Is that what you’re using on your blog?

What i don’t understood is actually how you’re not really much more well-liked than you may be right now. You are very intelligent. You realize thus significantly relating to this subject, produced me personally consider it from so many varied angles. Its like women and men aren’t fascinated unless it is one thing to accomplish with Lady gaga! Your own stuffs great. Always maintain it up!

Howdy! I just wish to give a huge thumbs up for the great information you may have here on this post. I will likely be coming again to your blog for extra soon.

Would you be fascinated about exchanging hyperlinks?

I am no longer sure where you are getting your information, however good topic. I needs to spend a while studying much more or figuring out more. Thanks for magnificent information I used to be searching for this information for my mission.

Today, I went to the beachfront with my kids. I found a sea shell and gave it to my 4 year old daughter and said “You can hear the ocean if you put this to your ear.” She put the shell to her ear and screamed. There was a hermit crab inside and it pinched her ear. She never wants to go back! LoL I know this is completely off topic but I had to tell someone!

This is the right blog for anyone who wants to find out about this topic. You realize so much its almost hard to argue with you (not that I actually would want…HaHa). You definitely put a new spin on a topic thats been written about for years. Great stuff, just great!

A powerful share, I simply given this onto a colleague who was doing a bit of evaluation on this. And he in fact purchased me breakfast as a result of I discovered it for him.. smile. So let me reword that: Thnx for the treat! But yeah Thnkx for spending the time to discuss this, I feel strongly about it and love reading more on this topic. If attainable, as you develop into expertise, would you mind updating your weblog with extra particulars? It’s highly useful for me. Massive thumb up for this weblog post!

This blog is definitely rather handy since I’m at the moment creating an internet floral website – although I am only starting out therefore it’s really fairly small, nothing like this site. Can link to a few of the posts here as they are quite. Thanks much. Zoey Olsen

I love the efforts you have put in this, thank you for all the great content.

After research a number of of the blog posts in your website now, and I actually like your means of blogging. I bookmarked it to my bookmark web site list and will probably be checking again soon. Pls try my web site as well and let me know what you think.

I’m typically to blogging and i really admire your content. The article has really peaks my interest. I’m going to bookmark your website and preserve checking for brand new information.

blacksprut.net официальная ссылка на сайт BLACKSPRUT

I am just commenting to let you know of the exceptional encounter my friend’s princess found reading the blog. She figured out too many details, which include what it’s like to possess an awesome helping character to get others clearly understand specific problematic subject areas. You really surpassed our own desires. I appreciate you for producing these priceless, safe, explanatory and even easy guidance on your topic to Lizeth.

I’m really loving the theme/design of your site. Do you ever run into any web browser compatibility issues? A handful of my blog visitors have complained about my blog not working correctly in Explorer but looks great in Firefox. Do you have any advice to help fix this problem?

I got what you intend, regards for posting.Woh I am happy to find this website through google.

I think other website proprietors should take this internet site as an model, very clean and fantastic user genial style.

I have not checked in here for some time because I thought it was getting boring, but the last several posts are good quality so I guess I will add you back to my daily bloglist. You deserve it my friend 🙂

Youre so cool! I dont suppose Ive read something like this before. So good to search out any person with some authentic thoughts on this subject. realy thank you for starting this up. this website is one thing that is needed on the internet, somebody with somewhat originality. helpful job for bringing something new to the web!

I love it when people come together and share opinions, great blog, keep it up.

Hey there! Do you use Twitter? I’d like to follow you if that would be okay. I’m absolutely enjoying your blog and look forward to new updates.

As a Newbie, I am continuously browsing online for articles that can be of assistance to me. Thank you

This is very interesting, You are a very skilled blogger. I’ve joined your feed and look forward to seeking more of your wonderful post. Also, I have shared your website in my social networks!

There are certainly loads of details like that to take into consideration. That may be a great level to carry up. I supply the thoughts above as basic inspiration however clearly there are questions just like the one you bring up where the most important thing will probably be working in trustworthy good faith. I don?t know if finest practices have emerged round issues like that, but I am sure that your job is clearly recognized as a fair game. Both boys and girls feel the impression of only a second’s pleasure, for the rest of their lives.

I besides conceive therefore, perfectly written post! .

Some genuinely marvelous work on behalf of the owner of this web site, utterly outstanding content material.

Outstanding post, I believe blog owners should learn a lot from this web site its real user pleasant.

I do trust all the concepts you have presented on your post. They are really convincing and will definitely work. Still, the posts are too short for novices. May just you please prolong them a little from next time? Thanks for the post.

Thank you, I have recently been searching for info approximately this topic for a while and yours is the greatest I’ve found out till now. But, what about the conclusion? Are you certain in regards to the source?

I simply couldn’t go away your site before suggesting that I really loved the standard info a person provide to your visitors? Is gonna be again ceaselessly to inspect new posts.

Pretty! This was a really wonderful post. Thank you for your provided information.

You can certainly see your skills in the work you write. The world hopes for even more passionate writers like you who aren’t afraid to say how they believe. Always go after your heart.

Very interesting information!Perfect just what I was searching for! “Energy is the power that drives every human being. It is not lost by exertion by maintained by it.” by Germaine Greer.

I have been examinating out some of your posts and i can state pretty good stuff. I will definitely bookmark your site.

I was looking through some of your blog posts on this website and I think this website is really instructive! Keep on posting.

Hey there! Quick question that’s completely off topic. Do you know how to make your site mobile friendly? My weblog looks weird when browsing from my iphone4. I’m trying to find a theme or plugin that might be able to resolve this problem. If you have any suggestions, please share. Many thanks!

Undeniably believe that which you said. Your favourite reason appeared to be on the internet the simplest factor to take note of. I say to you, I certainly get annoyed at the same time as other people consider concerns that they plainly do not recognise about. You managed to hit the nail upon the highest and defined out the entire thing with no need side effect , people could take a signal. Will probably be back to get more. Thank you

I am extremely impressed with your writing skills and also with the layout on your blog. Is this a paid theme or did you customize it yourself? Anyway keep up the excellent quality writing, it’s rare to see a great blog like this one nowadays..

Really wonderful info can be found on weblog.

I conceive this site has got very wonderful pent content material blog posts.

I?¦ll immediately clutch your rss feed as I can not in finding your e-mail subscription hyperlink or newsletter service. Do you have any? Kindly let me recognise in order that I could subscribe. Thanks.

Enjoyed looking through this, very good stuff, regards.

You could definitely see your enthusiasm within the paintings you write. The world hopes for even more passionate writers like you who aren’t afraid to say how they believe. At all times follow your heart. “Billy Almon has all of his inlaw and outlaws here this afternoon.” by Jerry Coleman.

Thanks for helping out, wonderful info .

Hey, I think your website might be having browser compatibility issues. When I look at your blog site in Ie, it looks fine but when opening in Internet Explorer, it has some overlapping. I just wanted to give you a quick heads up! Other then that, superb blog!

Hello.This article was really fascinating, particularly because I was investigating for thoughts on this subject last week.

I really like your blog.. very nice colors & theme. Did you create this website yourself or did you hire someone to do it for you? Plz respond as I’m looking to create my own blog and would like to find out where u got this from. thanks a lot

Only wanna input on few general things, The website style is perfect, the content is rattling wonderful : D.

Very interesting subject, regards for putting up. “The reason people sweat is so they won’t catch fire when making love.” by Don Rose.

You are my intake, I have few blogs and very sporadically run out from to post .

I am constantly browsing online for posts that can assist me. Thank you!

I haven?¦t checked in here for a while as I thought it was getting boring, but the last few posts are great quality so I guess I?¦ll add you back to my everyday bloglist. You deserve it my friend 🙂

I do love the manner in which you have presented this specific concern and it does indeed present me a lot of fodder for thought. Nevertheless, because of what precisely I have observed, I just simply hope as the actual feedback pack on that folks stay on point and in no way embark on a soap box associated with some other news of the day. Anyway, thank you for this excellent piece and though I can not necessarily go along with the idea in totality, I regard your viewpoint.

I like this weblog so much, bookmarked.

Today, I went to the beach with my children. I found a sea shell and gave it to my 4 year old daughter and said “You can hear the ocean if you put this to your ear.” She put the shell to her ear and screamed. There was a hermit crab inside and it pinched her ear. She never wants to go back! LoL I know this is entirely off topic but I had to tell someone!