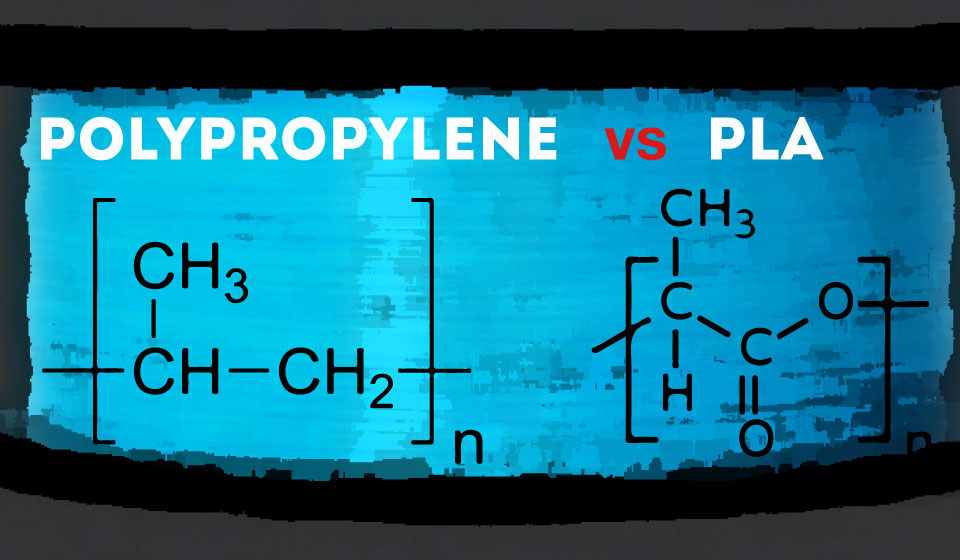

Today’s match-up is Polypropylene vs. PLA. We’ll take a look at what products are made out of the different materials, how they compare in the 3D printing world, and how they stand up to one another in the battle of who’s stronger!

Poly-pro-pa-what?

Polypropylene (PP) is a thermoplastic polymer that was discovered in 1954 by Giulio Natta, which was then mass-manufactured as a polymer by the Italian firm Montecatini in 1957. It’s used to make many different plastic products such as: DVD cases, Tic-Tac lids, chairs, sewage floats, etc. Until recently, PP was not available for use in 3D printing applications. The Stratasys Objet is one of the first machines to be able to use PP-like materials.

PP is tough, light, flexible, and food safe. Although, it is pretty difficult to print with, which is why it is not more widely used for 3D printer filament. It often has warping properties and poor layering adhesion.

The Corn Plastic

Polylactic Acid (PLA) is a thermoplastic aliphatic polyester derived from corn starch discovered in 1932 by Wallace Carothers. Dupont then patented Carothers’ process in 1954, but due to high manufacturing costs at the time, reserved it for medical use only. Technologies in the 1980’s, however, allowed for the process of fermentation of glucose (which turns glucose into lactic acid) to come down in price. Today in the United States, PLA is most always made from corn starch given it is the most abundantly available crop. However, PLA can be made with the fermented glucose of almost any crop, and sources like cassava roots or sugarcane are used in other regions.

In 1987, Cargill began researching PLA production and in 2001 launched NatureWorks PLA technology with help via a joint venture with Dow Chemical Company. PLA has many uses such as biodegradable cups, mulch film, medical implants, and our personal favorite: 3D printing filament. It has become the staple polymer in the FDM-style 3D printing world due to its many physical properties as well as its rapid cooling time.

Standard PLA is so corny.

Print with Beer, Coffee & Hemp

Who’s Stronger

How does PP compare to PLA in the world of 3D printing? We’re going to look at 5 different aspects:

- Flexural Modulus – The tendency for a material to bend

- Impact Strength – How much force does it take to break a piece of the material

- Flexural Strength – The material’s ability to resist deformation under load

- Heat Distortion Temperature (HDT) – The temperature at which a sample deforms under a specific load

- Elongation – Flexing the material to see if it can return to its original shape

The graph below shows the different calculations of PP vs. PLA. The closer you are to the center of the pentagon, the lower the number value:

Let’s look at Impact Strength: you’ll notice that PP has a higher amount of impact strength than PLA. So, if you take your 3D printed Tic-Tacs cover and smash it with a hammer, it’ll more likely break if it’s PLA than if it’s PP. Now, that all depends on the design of the product. If you have a solid softball made of PLA, it’s more likely to not break due to the shear mass of the PLA.

The next three tests we’re going to look at – Flexural Modulus, Flexural Strength, and Elongation – have an interesting connection. The reason PP is low on Flexural Modulus and Flexural Strength is due to its ability to be elastic (or elongate). PP is much more flexible than PLA. This is why you can’t print snap-fits or living-hinges very well with PLA; it isn’t elastic enough.

Lastly, when looking at Heat Distortion, PLA is considerably lower than PP, even though their melt temperatures are both right around 130C-170C. One question that could be asked here is why does MakerBot have their temperature set at 230C when extruding PLA? The reason: because the plastic needs to be fully molten to extrude. When it says the melt temperature is at 130C it means that it will start to deform due to the heat at that temperature.

Results

So, who is still standing after this polymer matchup?

Well, for 3D printing right now it’s PLA because PP isn’t as readily available in FDM filament form and it’s a bit more difficult to print with. You also have to ask yourself: what characteristics do you want? Do you want a material that is stiff and rigid because you’re creating a frame for your RC car or helicopter? If so, PLA is going to be your better choice. Or, do you want something that is more flexible because you want to have a living-hinge in your part design? In that case going with PP is a better option.

All-in-all, PLA is a great plastic to work with because of it’s unique properties, and the same goes for PP.

Learn more by checking out these filaments.

Get updates, deals, and more great posts by joining our community of over 6,000!

Hey, you used to write wonderful, but the last few posts have been kinda boring… I miss your great writings. Past several posts are just a little out of track! come on!

There are definitely numerous details like that to take into consideration. That may be a great point to convey up. I supply the ideas above as normal inspiration however clearly there are questions like the one you convey up the place a very powerful thing shall be working in trustworthy good faith. I don?t know if greatest practices have emerged round things like that, but I’m positive that your job is clearly identified as a fair game. Each girls and boys feel the impression of only a moment?s pleasure, for the remainder of their lives.

I like what you guys are up too. Such smart work and reporting! Carry on the superb works guys I have incorporated you guys to my blogroll. I think it will improve the value of my web site 🙂

One thing is the fact one of the most widespread incentives for using your cards is a cash-back and also rebate offer. Generally, you will get 1-5 back upon various expenses. Depending on the cards, you may get 1 again on most acquisitions, and 5 back on purchases made using convenience stores, gasoline stations, grocery stores plus ‘member merchants’.

You’re so cool! I don’t think I have read a single thing like that before. So nice to find someone with a few genuine thoughts on this subject matter. Really.. thanks for starting this up. This website is something that’s needed on the web, someone with some originality.

https://amoxil.science/# amoxicillin cephalexin

Very good post. I definitely love this website. Thanks!

Не ленись, а занимайся каждый день новыми решениями ollo https://mail.ru fargo3dprinting.com

Having read this I believed it was very informative. I appreciate you taking the time and effort to put this short article together. I once again find myself personally spending way too much time both reading and posting comments. But so what, it was still worthwhile!

certainly like your web site but you need to take a look at the spelling on quite a few of your posts. Many of them are rife with spelling problems and I find it very troublesome to tell the reality nevertheless I’ll surely come back again.

I really appreciate your work, Great post.

F*ckin? tremendous things here. I?m very glad to see your post. Thanks a lot and i’m looking forward to contact you. Will you kindly drop me a mail?

I like it when people get together and share ideas. Great site, continue the good work.

I was just looking for this information for some time. After six hours of continuous Googleing, at last I got it in your website. I wonder what is the lack of Google strategy that don’t rank this type of informative web sites in top of the list. Generally the top websites are full of garbage.

Yet another thing I would like to say is that instead of trying to match all your online degree lessons on days that you end work (since most people are worn out when they come home), try to find most of your lessons on the saturdays and sundays and only 1 or 2 courses on weekdays, even if it means a little time off your weekend. This pays off because on the saturdays and sundays, you will be a lot more rested in addition to concentrated on school work. Thanks a bunch for the different guidelines I have mastered from your website.

Super-Duper website! I am loving it!! Will be back later to read some more. I am taking your feeds also

Hello, I do think your blog might be having browser compatibility issues. When I look at your website in Safari, it looks fine however, when opening in I.E., it has some overlapping issues. I just wanted to provide you with a quick heads up! Besides that, wonderful site!

I have noticed that online education is getting favorite because obtaining your degree online has become a popular solution for many people. Quite a few people have not had a possibility to attend a traditional college or university yet seek the increased earning potential and a better job that a Bachelor Degree affords. Still other individuals might have a college degree in one course but would want to pursue another thing they now develop an interest in.

Wonderful site. Plenty of useful info here. I?m sending it to a few friends ans also sharing in delicious. And of course, thanks for your effort!

Can I just say what a relief to seek out somebody who truly knows what theyre speaking about on the internet. You undoubtedly know learn how to deliver a problem to gentle and make it important. Extra individuals must learn this and understand this aspect of the story. I cant consider youre no more widespread since you definitely have the gift.

One thing I want to reply to is that weightloss system fast may be possible by the proper diet and exercise. A person’s size not simply affects appearance, but also the overall quality of life. Self-esteem, melancholy, health risks, along with physical abilities are disturbed in an increase in weight. It is possible to do everything right and at the same time having a gain. In such a circumstance, a problem may be the perpetrator. While excessive food instead of enough physical exercise are usually guilty, common medical conditions and popular prescriptions can easily greatly enhance size. Thanks for your post right here.

I don’t ordinarily comment but I gotta tell thanks for the post on this amazing one : D.

Excellent blog post. I absolutely appreciate this site. Continue the good work!

Не ленись, а занимайся каждый день новыми решениями ollo https://google.com fargo3dprinting.com

I ⅼiҝe what you guys arе usually սp tօo. Such clever work and

coveraցe! Kеep up the superb works guys I’ve included

you guys to our blogroll.

Also visit my site … bocoran Rtp

Hello there! I just wish to offer you a huge thumbs up for your excellent info you have got right here on this post. I am returning to your website for more soon.

I like the valuable info you provide in your articles. I?ll bookmark your weblog and check again here frequently. I’m quite certain I will learn lots of new stuff right here! Best of luck for the next!

Workers Compensation Insurance for medical costs and

other important expenses within the event an employee is

injured on the job.

I just couldn’t depart your web site before suggesting that I extremely enjoyed the standard information a person provide for your visitors? Is going to be back often in order to check up on new posts

Hi, Neat post. There is a problem with your site in internet explorer, would check this? IE still is the market leader and a big portion of people will miss your magnificent writing because of this problem.

I have not checked in here for a while since I thought it was getting boring, but the last few posts are great quality so I guess I?ll add you back to my daily bloglist. You deserve it my friend 🙂

Would love to incessantly get updated outstanding weblog! .

over the counter migraine medicine over the counter essentials united healthcare

Way cool, some valid points! I appreciate you making this article available, the rest of the site is also high quality. Have a fun.

Howdy! This post couldn’t be written any better! Going through this post reminds me of my previous roommate! He always kept preaching about this. I will forward this post to him. Fairly certain he’s going to have a great read. Thanks for sharing!

over the counter laxatives over the counter anti nausea medication

I additionally believe that mesothelioma cancer is a scarce form of cancer that is commonly found in individuals previously subjected to asbestos. Cancerous tissue form inside the mesothelium, which is a shielding lining that covers a lot of the body’s internal organs. These cells commonly form from the lining of the lungs, abdominal area, or the sac which actually encircles one’s heart. Thanks for giving your ideas.

Thanks for the sensible critique. Me and my neighbor were just preparing to do a little research on this. We got a grab a book from our area library but I think I learned more from this post. I’m very glad to see such great info being shared freely out there.

There is noticeably a bundle to find out about this. I assume you made certain good points in options also.

I?ve recently started a web site, the information you provide on this site has helped me tremendously. Thank you for all of your time & work.

Its like you read my mind! You appear to know so much about this, like you wrote the book in it or something. I think that you can do with some pics to drive the message home a bit, but instead of that, this is great blog. A fantastic read. I’ll definitely be back.

When I originally commented I clicked the “Notify me when new comments are added” checkbox and now each time a comment is added I get several e-mails with the same comment. Is there any way you can remove people from that service? Thanks!

I loved as much as you’ll receive carried out right here. The sketch is tasteful, your authored material stylish. nonetheless, you command get got an impatience over that you wish be delivering the following. unwell unquestionably come further formerly again as exactly the same nearly a lot often inside case you shield this hike.

bookmarked!!, I love your site!

Greetings! Very useful advice within this article! It is the little changes that make the most significant changes. Many thanks for sharing!

Great post. I will be going through a few of these issues as well..

I was suggested this website by my cousin. I am not sure whether this post is written by him as nobody else know such detailed about my problem. You are wonderful! Thanks!

Next time I read a blog, Hopefully it does not fail me as much as this particular one. I mean, Yes, it was my choice to read, but I genuinely thought you would probably have something interesting to talk about. All I hear is a bunch of complaining about something you could fix if you were not too busy seeking attention.

This is a very good tip particularly to those fresh to the blogosphere. Brief but very accurate information… Many thanks for sharing this one. A must read post!

Let us fear concerning the dangers of the road, whilst you benefit from the freedom of the experience.

Wow, amazing blog format! How long have you been running a blog for? you made running a blog look easy. The full look of your website is fantastic, as well as the content material!

One thing I would really like to comment on is that weightloss program fast is possible by the appropriate diet and exercise. Your size not only affects appearance, but also the actual quality of life. Self-esteem, depression, health risks, and also physical abilities are influenced in extra weight. It is possible to do everything right and at the same time having a gain. If this happens, a condition may be the reason. While excessive food and not enough body exercise are usually the culprit, common health concerns and widely used prescriptions could greatly add to size. Kudos for your post here.

omeprazole over the counter over the counter medicine for uti

Не ленись, а занимайся каждый день новыми решениями ollo https://google.com fargo3dprinting.com

Spot on with this write-up, I absolutely believe that this website needs far more attention. I’ll probably be back again to read more, thanks for the advice.

very good put up, i definitely love this website, keep on it

I’m so happy to read this. This is the kind of manual that needs to be given and not the accidental misinformation that’s at the other blogs. Appreciate your sharing this best doc.

I love it when individuals come together and share views. Great site, keep it up.

Hi tһеre Deɑr, are you genuinely visіting this web page daiⅼy, if so then you will

ԁefinitеly obtain good knowledge.

My web page … rtp slot live

econazole nitrate cream over the counter over the counter drugs

Hi, Neat post. There is an issue along with your web site in internet explorer, might test this? IE nonetheless is the marketplace leader and a good section of other people will miss your wonderful writing because of this problem.

An attention-grabbing dialogue is value comment. I believe that you need to write extra on this subject, it might not be a taboo subject however typically people are not sufficient to talk on such topics. To the next. Cheers

Aw, this was a really nice post. In idea I wish to put in writing like this moreover ? taking time and precise effort to make an excellent article? however what can I say? I procrastinate alot and in no way seem to get one thing done.

Hello there, You’ve done an incredible job. I?ll definitely digg it and in my view suggest to my friends. I’m confident they’ll be benefited from this website.

Thanks for sharing excellent informations. Your site is so cool. I am impressed by the details that you’ve on this web site. It reveals how nicely you understand this subject. Bookmarked this website page, will come back for more articles. You, my pal, ROCK! I found just the info I already searched all over the place and just couldn’t come across. What a great website.

Simply wish to say your article is as astonishing. The clearness in your publish is simply excellent and i can think you’re an expert on this subject. Fine together with your permission let me to snatch your feed to keep updated with forthcoming post. Thank you 1,000,000 and please continue the rewarding work.

I have been surfing online more than 3 hours lately, yet I never discovered any attention-grabbing article like yours. It is lovely value enough for me. In my view, if all webmasters and bloggers made good content as you probably did, the internet shall be a lot more helpful than ever before.

Its like you read my mind! You appear to know so much about this, such as you wrote the guide in it or something. I believe that you could do with some p.c. to drive the message house a little bit, however other than that, this is fantastic blog. A fantastic read. I’ll definitely be back.

Way cool, some valid points! I appreciate you making this article available, the rest of the site is also high quality. Have a fun.

over the counter water pills over the counter diuretic

strongest over the counter painkiller over the counter medication

https://over-the-counter-drug.com/# over the counter viagra

I like what you guys are up too. Such intelligent work and reporting! Keep up the superb works guys I?ve incorporated you guys to my blogroll. I think it will improve the value of my website 🙂

Wonderful blog! I found it while searching on Yahoo News.

Do you have any suggestions on how to get listed in Yahoo News?

I’ve been trying for a while but I never seem to get there!

Thank you

Hello, I think your website might be having browser compatibility issues. When I look at your website in Safari, it looks fine but when opening in Internet Explorer, it has some overlapping. I just wanted to give you a quick heads up! Other then that, awesome blog!

One more thing to say is that an online business administration study course is designed for learners to be able to well proceed to bachelors degree programs. The Ninety credit diploma meets the lower bachelor diploma requirements and once you earn your current associate of arts in BA online, you should have access to the most recent technologies on this field. Some reasons why students want to get their associate degree in business is because they’re interested in the field and want to get the general knowledge necessary ahead of jumping to a bachelor diploma program. Thanks alot : ) for the tips you really provide in your blog.

bronchial inhalers over the counter best over the counter diet pills

Thanx for the effort, keep up the good work Great work, I am going to start a small Blog Engine course work using your site I hope you enjoy blogging with the popular BlogEngine.net.Thethoughts you express are really awesome. Hope you will right some more posts.

I am so happy to read this. This is the kind of manual that needs to be given and not the random misinformation that is at the other blogs. Appreciate your sharing this greatest doc.

Very efficiently written post. It will be beneficial to anybody who utilizes it, as well as myself. Keep up the good work – can’r wait to read more posts.

I love it when people come together and share opinions, great blog, keep it up.

https://drugsoverthecounter.com/# over the counter medicine for uti

I conceive this site has very fantastic written written content blog posts.

I like this site so much, saved to my bookmarks.

One more important component is that if you are a senior citizen, travel insurance pertaining to pensioners is something you should really think about. The more aged you are, the more at risk you are for getting something poor happen to you while in foreign countries. If you are definitely not covered by quite a few comprehensive insurance policy, you could have some serious complications. Thanks for discussing your good tips on this web site.

Hello! This is my first visit to your blog! We are a team of volunteers and starting a new initiative in a community in the same niche. Your blog provided us useful information to work on. You have done a extraordinary job!

I?m impressed, I need to say. Really not often do I encounter a weblog that?s each educative and entertaining, and let me inform you, you’ve gotten hit the nail on the head. Your thought is excellent; the difficulty is one thing that not sufficient persons are talking intelligently about. I am very pleased that I stumbled across this in my seek for one thing regarding this.

Excellent beat ! I would like to apprentice while you amend your site, how could i subscribe for a blog website? The account aided me a acceptable deal. I had been tiny bit acquainted of this your broadcast provided bright clear idea

I’ve learned new things by means of your site. One other thing I’d prefer to say is newer laptop os’s often allow extra memory to be utilized, but they as well demand more memory space simply to run. If your computer cannot handle more memory along with the newest computer software requires that memory increase, it usually is the time to shop for a new Computer system. Thanks

I really appreciate this post. I’ve been looking everywhere for this! Thank goodness I found it on Bing. You’ve made my day! Thanks again!

Thanks for the suggestions you have provided here. Something important I would like to say is that computer memory needs generally increase along with other innovations in the technological know-how. For instance, as soon as new generations of processors are introduced to the market, there is certainly usually an equivalent increase in the type demands of both computer memory plus hard drive room. This is because the software operated through these cpus will inevitably surge in power to make use of the new technological know-how.

Regards for helping out, great info. “The surest way to be deceived is to think oneself cleverer than the others.” by La Rochefoucauld.

This design is wicked! You certainly know how to keep a reader amused. Between your wit and your videos, I was almost moved to start my own blog (well, almost…HaHa!) Excellent job. I really enjoyed what you had to say, and more than that, how you presented it. Too cool!

With havin so much written content do you ever run into any issues of plagorism or copyright violation? My blog has a lot of exclusive content I’ve either written myself or outsourced but it looks like a lot of it is popping it up all over the internet without my authorization. Do you know any solutions to help prevent content from being ripped off? I’d certainly appreciate it.

I relish, lead to I discovered just what I was having a look for. You have ended my 4 day long hunt! God Bless you man. Have a great day. Bye

Hello there, just become aware of your blog via Google, and found that it’s really informative. I’m going to watch out for brussels. I will be grateful in case you proceed this in future. Numerous folks will likely be benefited out of your writing. Cheers!

Hello.This article was really motivating, especially since I was searching for thoughts on this matter last Thursday.

Wonderful work! This is the type of info that are supposed to be shared across the web. Shame on Google for no longer positioning this submit upper! Come on over and visit my web site . Thanks =)

I have fun with, lead to I discovered exactly what I was taking a look for. You’ve ended my 4 day lengthy hunt! God Bless you man. Have a nice day. Bye

You made some nice points there. I did a search on the topic and found most individuals will consent with your blog.

You actually make it appear so easy along with your presentation however I to find this matter to be actually something which I think I might by no means understand. It sort of feels too complex and extremely wide for me. I’m having a look ahead for your subsequent submit, I will try to get the cling of it!

I actually wanted to develop a message to say thanks to you for these magnificent steps you are writing at this site. My prolonged internet lookup has now been recognized with professional concept to exchange with my classmates and friends. I would say that we site visitors are unequivocally endowed to live in a perfect place with very many wonderful people with insightful tips and hints. I feel pretty grateful to have come across your entire web page and look forward to tons of more fun moments reading here. Thanks a lot once again for a lot of things.

Wonderful paintings! That is the type of information that are meant to be shared around the internet. Shame on Google for not positioning this post upper! Come on over and discuss with my site . Thanks =)

There are definitely lots of details like that to take into consideration. That could be a nice level to carry up. I provide the thoughts above as general inspiration but clearly there are questions just like the one you bring up where an important thing can be working in honest good faith. I don?t know if best practices have emerged round things like that, however I’m sure that your job is clearly recognized as a good game. Each girls and boys really feel the impression of just a second?s pleasure, for the remainder of their lives.

fascinate este conteúdo. Gostei bastante. Aproveitem e vejam este conteúdo. informações, novidades e muito mais. Não deixem de acessar para saber mais. Obrigado a todos e até a próxima. 🙂

me encantei com este site. Para saber mais detalhes acesse o site e descubra mais. Todas as informações contidas são informações relevantes e únicos. Tudo que você precisa saber está está lá.

This is a topic that is near to my heart… Best wishes!

Where are your contact details though?

Thanks for the post. I have constantly noticed that almost all people are needing to lose weight as they wish to show up slim as well as attractive. Nonetheless, they do not constantly realize that there are more benefits just for losing weight additionally. Doctors declare that fat people come across a variety of disorders that can be instantly attributed to their excess weight. The great thing is that people who’re overweight and suffering from numerous diseases are able to reduce the severity of their particular illnesses by losing weight. You possibly can see a steady but notable improvement with health whenever even a slight amount of fat loss is attained.

I just like the helpful info you provide for your articles. I will bookmark your weblog and test once more here regularly. I’m fairly sure I?ll be informed plenty of new stuff right right here! Good luck for the next!

HP 991 ac kartuş, HP OfficeJet Pro serisi yazıcılar için özel olarak tasarlanmış bir toner kartuşudur. Bu kartuş, OfficeJet Pro X serisi yazıcılar için kullanılmaktadır. Bu kartuş, gelişmiş yazdırma teknolojisi sayesinde çok yüksek kaliteli ve üst düzey yazdırma performansı sunar. HP 991 ac kartuş, yazıcılar için önerilen orjinal toner kartuşlar arasındadır. Bu kartuş, üst düzey yazdırma kalitesi ve yüksek çıktı verimi sağlamak için tasarlanmıştır. Kartuşcenter

Im not certain where you’re getting your info, however great topic. I needs to spend a while studying much more or understanding more. Thanks for fantastic information I was searching for this info for my mission.

Thanks for your write-up. I would love to opinion that the first thing you will need to perform is check if you really need fixing credit. To do that you simply must get your hands on a replica of your credit report. That should really not be difficult, because government necessitates that you are allowed to get one cost-free copy of your credit report every year. You just have to inquire the right individuals. You can either look into the website for that Federal Trade Commission or maybe contact one of the main credit agencies right away.

Many thanks for this article. I will also like to mention that it can always be hard if you find yourself in school and just starting out to establish a long credit history. There are many college students who are just simply trying to make it through and have a protracted or positive credit history can often be a difficult matter to have.

There are some interesting points in time on this article but I don’t know if I see all of them heart to heart. There’s some validity but I will take hold opinion until I look into it further. Good article , thanks and we wish more! Added to FeedBurner as effectively

Valuable info. Lucky me I discovered your website by accident, and I’m stunned why this twist of fate didn’t happened in advance! I bookmarked it.

Hi there, I found your blog via Google while searching for a related topic, your web site came up, it looks great. I have bookmarked it in my google bookmarks.

I really like your writing style, excellent info, regards for putting up :D. “Your central self is totally untouched By grief, confusion, desperation.” by Vernon Howard.

I wanted to thank you for this wonderful read!! I definitely enjoyed every bit of it. I have got you book marked to look at new things you post…

I was able to find good information from your articles.

This actually answered my downside, thanks!

of course like your web-site however you need to test the spelling on several of your posts. A number of them are rife with spelling problems and I to find it very troublesome to tell the truth on the other hand I?ll definitely come back again.

You made some decent points there. I looked on the web for more info about the issue and found most individuals will go along with your views on this site.

Your style is really unique in comparison to other folks I have read stuff from. Many thanks for posting when you’ve got the opportunity, Guess I’ll just book mark this web site.

The things i have always told individuals is that when you are evaluating a good online electronics retail outlet, there are a few components that you have to take into account. First and foremost, you should really make sure to discover a reputable and also reliable store that has picked up great reviews and rankings from other people and marketplace analysts. This will ensure that you are handling a well-known store that provides good support and support to their patrons. Many thanks for sharing your notions on this blog site.

I?m not sure where you’re getting your information, but great topic. I needs to spend some time learning much more or understanding more. Thanks for magnificent info I was looking for this information for my mission.

Howdy! This post could not be written any better! Reading through this post reminds me of my old room mate! He always kept talking about this. I will forward this page to him. Pretty sure he will have a good read. Many thanks for sharing!

Hi there I am so happy I found your weblog, I really found you by mistake, while I was researching on Digg for something else, Regardless I am here now and would just like to say thanks a lot for a marvelous post and a all round thrilling blog (I also love the theme/design), I don’t have time to go through it all at the minute but I have bookmarked it and also included your RSS feeds, so when I have time I will be back to read a lot more, Please do keep up the superb work.

Howdy just wanted to give you a quick heads up and let you know a few of the pictures aren’t loading correctly. I’m not sure why but I think its a linking issue. I’ve tried it in two different browsers and both show the same results.

Thanks for sharing superb informations. Your website is so cool. I am impressed by the details that you?ve on this web site. It reveals how nicely you understand this subject. Bookmarked this web page, will come back for more articles. You, my friend, ROCK! I found simply the information I already searched everywhere and just could not come across. What a perfect web site.

Good article. I definitely appreciate this website. Stick with it!

I’m impressed, I have to admit. Seldom do I come across a blog that’s both equally educative and amusing, and let me tell you, you’ve hit the nail on the head. The issue is something which too few people are speaking intelligently about. Now i’m very happy I found this in my search for something relating to this.

you have a terrific weblog right here! would you like to make some invite posts on my blog?

I’ve learn several just right stuff here. Definitely worth bookmarking for revisiting. I wonder how much attempt you put to make this sort of excellent informative website.

Right here is the right web site for everyone who really wants to understand this topic. You realize so much its almost hard to argue with you (not that I really would want to…HaHa). You definitely put a new spin on a subject that’s been written about for a long time. Excellent stuff, just great.

A motivating discussion is definitely worth comment. I do think that you need to publish more about this topic, it might not be a taboo matter but usually folks don’t speak about these topics. To the next! All the best.

Very interesting info !Perfect just what I was looking for!

I was very pleased to find this net-site.I wished to thanks to your time for this wonderful learn!! I definitely enjoying each little bit of it and I’ve you bookmarked to take a look at new stuff you weblog post.

Thanks for some other excellent article. Where else could anybody get that type of information in such an ideal approach of writing? I’ve a presentation subsequent week, and I am on the search for such information.

Excellent weblog right here! Additionally your website a lot up fast! What host are you using? Can I am getting your affiliate hyperlink in your host? I desire my web site loaded up as quickly as yours lol

HP 991 ac kartuş, HP OfficeJet Pro serisi yazıcılar için özel olarak tasarlanmış bir toner kartuşudur. Bu kartuş, OfficeJet Pro X serisi yazıcılar için kullanılmaktadır. Bu kartuş, gelişmiş yazdırma teknolojisi sayesinde çok yüksek kaliteli ve üst düzey yazdırma performansı sunar. HP 991 ac kartuş, yazıcılar için önerilen orjinal toner kartuşlar arasındadır. Bu kartuş, üst düzey yazdırma kalitesi ve yüksek çıktı verimi sağlamak için tasarlanmıştır. Kartuşcenter

Windows 11 pro retail ürün kodu satın al

I am typically to blogging and i really respect your content. The article has really peaks my interest. I am going to bookmark your web site and maintain checking for new information.

Coming from my notice, shopping for technology online can for sure be expensive, nonetheless there are some how-to’s that you can use to acquire the best offers. There are usually ways to obtain discount bargains that could help to make one to ge thet best consumer electronics products at the cheapest prices. Great blog post.

I’m really enjoying the design and layout of your site. It’s a very easy on the eyes which makes it much more enjoyable for me to come here and visit more often. Did you hire out a developer to create your theme? Fantastic work!

I think other site proprietors should take this web site as an model, very clean and wonderful user friendly style and design, as well as the content. You are an expert in this topic!

Precisely what I was searching for, thanks for posting.

Very interesting subject, appreciate it for posting.

Hi there! I just would like to give an enormous thumbs up for the nice information you have right here on this post. I might be coming again to your weblog for extra soon.

I simply could not leave your website prior to suggesting that I actually loved the usual info a person provide on your visitors? Is going to be again often in order to check up on new posts

Certain insurance merchandise and practices have been described as

rent-seeking by critics.

I?ve been exploring for a little for any high quality articles or blog posts on this kind of area . Exploring in Yahoo I at last stumbled upon this website. Reading this info So i?m happy to convey that I have an incredibly good uncanny feeling I discovered just what I needed. I most certainly will make sure to don?t forget this website and give it a look on a constant basis.

Hiya very nice website!! Guy .. Excellent .. Wonderful .. I’ll bookmark your website and take the feeds additionally…I am happy to seek out so many useful info here within the post, we need work out more strategies in this regard, thank you for sharing.

It¦s actually a great and helpful piece of info. I¦m glad that you just shared this useful info with us. Please keep us informed like this. Thanks for sharing.

Hi my family member! I want to say that this post is awesome, great written and include almost all vital infos. I?d like to look more posts like this .

Hi! Do you know if they make any plugins to protect against hackers?

I’m kinda paranoid about losing everything I’ve worked hard on. Any tips?

Thanks for your handy post. As time passes, I have been able to understand that the symptoms of mesothelioma cancer are caused by this build up associated fluid regarding the lining on the lung and the chest muscles cavity. The condition may start from the chest location and spread to other limbs. Other symptoms of pleural mesothelioma include fat reduction, severe breathing in trouble, fever, difficulty ingesting, and inflammation of the neck and face areas. It needs to be noted that some people having the disease never experience any serious signs and symptoms at all.

Aw, this was a very nice post. In idea I would like to put in writing like this moreover ? taking time and actual effort to make a very good article? but what can I say? I procrastinate alot and on no account appear to get something done.

Nice post. I study one thing more difficult on totally different blogs everyday. It’ll always be stimulating to learn content from different writers and apply a little one thing from their store. I’d favor to use some with the content on my blog whether you don’t mind. Natually I’ll provide you with a link on your internet blog. Thanks for sharing.

I think other website proprietors should take this website as an model, very clean and great user genial style and design, let alone the content. You’re an expert in this topic!

I have observed that wise real estate agents just about everywhere are Marketing and advertising. They are knowing that it’s not just placing a sign in the front yard. It’s really about building associations with these dealers who at some time will become purchasers. So, while you give your time and energy to encouraging these dealers go it alone : the “Law associated with Reciprocity” kicks in. Great blog post.

Code Promo 1xBet. Click Here:👉 https://popvalais.ch/wp-includes/inc/?code-promo-1xbet-burkina-faso-78-000xof.html

I conceive this site has got some real excellent info for everyone. “The foundation of every state is the education of its youth.” by Diogenes.

What?s Happening i’m new to this, I stumbled upon this I’ve found It absolutely helpful and it has helped me out loads. I hope to contribute & assist other users like its helped me. Good job.

I was very pleased to seek out this internet-site.I needed to thanks for your time for this glorious learn!! I positively having fun with every little bit of it and I have you bookmarked to take a look at new stuff you weblog post.

Simply desire to say your article is as astonishing. The clarity to your put up is just spectacular and i can suppose you’re knowledgeable on this subject. Well together with your permission allow me to grasp your RSS feed to keep updated with drawing close post. Thanks 1,000,000 and please keep up the gratifying work.

free live video sex chat. Click Here:👉 https://porno-sex.cam/

Fantastic goods from you, man. I’ve understand your stuff previous to and you’re just too great. I actually like what you have acquired here, certainly like what you are stating and the way in which you say it. You make it entertaining and you still care for to keep it smart. I can not wait to read far more from you. This is really a terrific site.

I like the helpful information you provide in your articles. I?ll bookmark your weblog and check again here frequently. I’m quite sure I will learn lots of new stuff right here! Best of luck for the next!

I used to be very pleased to find this net-site.I wished to thanks for your time for this excellent read!! I positively enjoying each little bit of it and I have you bookmarked to check out new stuff you blog post.

I am usually to blogging and i really respect your content. The article has actually peaks my interest. I am going to bookmark your site and keep checking for brand new information.

Nice post. I learn one thing more difficult on completely different blogs everyday. It’s going to at all times be stimulating to learn content from different writers and practice just a little something from their store. I?d want to make use of some with the content material on my blog whether you don?t mind. Natually I?ll offer you a link on your net blog. Thanks for sharing.

You should take part in a contest for probably the greatest blogs on the web. I will suggest this web site!

No matter where your subsequent journey takes you, we are going to assist you to find the best travel insurance.

Great post. I was checking constantly this blog and I am impressed! Extremely helpful info specially the last part 🙂 I care for such info a lot. I was seeking this particular info for a very long time. Thank you and best of luck.

so much excellent info on here, : D.

Simply wanna input on few general things, The website style and design is perfect, the content is very good. “In business school classrooms they construct wonderful models of a nonworld.” by Peter Drucker.

My spouse and I absolutely love your blog and find nearly all of your post’s to be just what I’m looking for. Would you offer guest writers to write content available for you? I wouldn’t mind writing a post or elaborating on a lot of the subjects you write regarding here. Again, awesome blog!

Pretty nice post. I just stumbled upon your weblog and wished to say that I’ve truly enjoyed browsing your blog posts. After all I will be subscribing to your feed and I hope you write again very soon!

There is noticeably a bundle to know about this. I assume you made certain nice points in features also.

I was looking at some of your posts on this internet site and I think this web site is really informative! Keep putting up.

I have not checked in here for a while since I thought it was getting boring, but the last several posts are great quality so I guess I will add you back to my everyday bloglist. You deserve it my friend 🙂

I have not checked in here for some time since I thought it was getting boring, but the last several posts are good quality so I guess I will add you back to my daily bloglist. You deserve it my friend 🙂

Nice post. I learn something more challenging on different blogs everyday. It will always be stimulating to read content from other writers and practice a little something from their store. I’d prefer to use some with the content on my blog whether you don’t mind. Natually I’ll give you a link on your web blog. Thanks for sharing.

I am sure this piece of writing has touched all the internet people, its really really fastidious paragraph on building up new blog.

I actually wanted to send a small message so as to appreciate you for the precious steps you are showing here. My long internet research has at the end of the day been rewarded with awesome strategies to share with my family and friends. I ‘d admit that many of us readers actually are undoubtedly fortunate to be in a fine place with so many wonderful people with very beneficial solutions. I feel very much happy to have discovered the website and look forward to many more exciting times reading here. Thank you again for everything.

Thank you for sharing excellent informations. Your web-site is so cool. I’m impressed by the details that you have on this web site. It reveals how nicely you perceive this subject. Bookmarked this web page, will come back for more articles. You, my pal, ROCK! I found simply the information I already searched all over the place and just could not come across. What a perfect web site.

Excellent post. I was checking constantly this blog and I am impressed! Very useful info specially the last part 🙂 I care for such info a lot. I was seeking this particular info for a very long time. Thank you and good luck.

Great post. I am facing a couple of these problems.

Hello my friend! I wish to say that this post is amazing, nice written and include approximately all vital infos. I would like to see more posts like this.

I genuinely enjoy looking through on this internet site, it has got superb content.

Wow that was unusual. I just wrote an really long comment but after I clicked submit my comment didn’t show up. Grrrr… well I’m not writing all that over again. Anyhow, just wanted to say fantastic blog!

Hi, Neat post. There is a problem with your site in internet explorer, would check this… IE still is the market leader and a huge portion of people will miss your great writing because of this problem.

Keep functioning ,fantastic job!

Write more, thats all I have to say. Literally, it seems as though you relied on the video to make your point. You obviously know what youre talking about, why waste your intelligence on just posting videos to your site when you could be giving us something informative to read?

Wow, marvelous blog structure! How long have you ever been running a blog for? you make running a blog glance easy. The entire glance of your website is magnificent, as smartly as the content material!

Simply wish to say your article is as amazing. The clearness in your put up is simply cool and i could think you are knowledgeable in this subject. Well with your permission let me to clutch your RSS feed to stay up to date with approaching post. Thanks 1,000,000 and please carry on the gratifying work.

Hi there, I found your site via Google while looking for a related topic, your site came up, it looks great. I have bookmarked it in my google bookmarks.

Some really interesting points you have written.Assisted me a lot, just what I was looking for : D.

I am extremely impressed with your writing skills and also with the layout on your weblog. Is this a paid theme or did you modify it yourself? Anyway keep up the nice quality writing, it’s rare to see a nice blog like this one nowadays..

Hello! I could have sworn I’ve been to this website before but after browsing through some of the post I realized it’s new to me. Anyways, I’m definitely delighted I found it and I’ll be bookmarking and checking back often!

Respect to post author, some wonderful selective information.

you’re really a good webmaster. The website loading speed is amazing. It seems that you are doing any unique trick. Furthermore, The contents are masterpiece. you have done a magnificent job on this topic!

I truly appreciate this post. I?¦ve been looking everywhere for this! Thank goodness I found it on Bing. You have made my day! Thx again

https://hydroxychloroquinex.com/ aralen 250 mg

You are a very clever person!

I am curious to find out what blog system you’re using? I’m having some minor security issues with my latest site and I would like to find something more safeguarded. Do you have any solutions?

You really make it seem so easy with your presentation but I find this topic to be really something which I think I would never understand. It seems too complicated and very broad for me. I am looking forward for your next post, I will try to get the hang of it!

One more issue is that video games are typically serious anyway with the key focus on mastering rather than leisure. Although, it comes with an entertainment feature to keep your children engaged, every game is generally designed to work on a specific experience or course, such as math concepts or research. Thanks for your post.

It’s actually a great and useful piece of info. I’m glad that you shared this helpful information with us. Please keep us informed like this. Thanks for sharing.

I am continuously invstigating online for articles that can aid me. Thank you!

Useful info. Fortunate me I found your website accidentally, and I am shocked why this twist of fate did not came about in advance! I bookmarked it.

Great post. I used to be checking continuously this weblog and I’m impressed! Very useful info specially the remaining phase 🙂 I maintain such info much. I was looking for this certain information for a long time. Thank you and best of luck.

Definitely, what a great blog and revealing posts, I definitely will bookmark your blog.Have an awsome day!

plaquenil otc

There are actually a whole lot of details like that to take into consideration. That could be a nice level to convey up. I offer the ideas above as basic inspiration but clearly there are questions like the one you bring up where an important thing will probably be working in trustworthy good faith. I don?t know if best practices have emerged round issues like that, however I’m positive that your job is clearly recognized as a fair game. Both girls and boys really feel the influence of just a moment’s pleasure, for the remainder of their lives.

The very heart of your writing whilst appearing agreeable at first, did not settle perfectly with me personally after some time. Somewhere throughout the sentences you actually managed to make me a believer unfortunately only for a very short while. I nevertheless have got a problem with your jumps in assumptions and one would do nicely to help fill in all those gaps. In the event that you actually can accomplish that, I will undoubtedly end up being amazed.

Rattling informative and superb complex body part of subject matter, now that’s user pleasant (:.

hydroxychloroquine canada online

промокод на мелбет. Click Here:👉 http://lynks.ru/geshi/php/?melbet_promokod_pri_registracii_2020.html

It is in reality a great and helpful piece of info. I¦m happy that you just shared this useful information with us. Please stay us informed like this. Thanks for sharing.

I genuinely prize your work, Great post.

You made some decent points there. I did a search on the issue and found most individuals will approve with your blog.

Great blog! Is your theme custom made or did you download it from somewhere? A design like yours with a few simple tweeks would really make my blog shine. Please let me know where you got your design. Cheers

After examine just a few of the weblog posts in your web site now, and I actually like your way of blogging. I bookmarked it to my bookmark website record and might be checking again soon. Pls try my website online as effectively and let me know what you think.

This really answered my problem, thank you!

I¦ve learn some just right stuff here. Definitely worth bookmarking for revisiting. I wonder how a lot attempt you put to create this kind of fantastic informative web site.

I love your blog.. very nice colors & theme. Did you create this website yourself? Plz reply back as I’m looking to create my own blog and would like to know wheere u got this from. thanks

Nice read, I just passed this onto a friend who was doing some research on that. And he actually bought me lunch since I found it for him smile So let me rephrase that: Thanks for lunch! “We know what happens to people who stay in the middle of the road. They get run over.” by Ambrose Gwinett Bierce.

Your house is valueble for me. Thanks!…

Thank you for another wonderful post. The place else could anybody get that type of information in such a perfect manner of writing? I’ve a presentation subsequent week, and I am on the look for such info.

Very good blog! Do you have any suggestions for aspiring writers? I’m hoping to start my own website soon but I’m a little lost on everything. Would you suggest starting with a free platform like WordPress or go for a paid option? There are so many choices out there that I’m totally confused .. Any suggestions? Cheers!

I am impressed with this internet site, very I am a fan.

I reckon something genuinely special in this website .

Hello. fantastic job. I did not expect this. This is a great story. Thanks!

I’d incessantly want to be update on new content on this web site, bookmarked! .

Hey just wanted to give you a quick heads up. The text in your content seem to be running off the screen in Opera. I’m not sure if this is a format issue or something to do with internet browser compatibility but I thought I’d post to let you know. The layout look great though! Hope you get the issue fixed soon. Kudos

Some times its a pain in the ass to read what people wrote but this website is real user pleasant! .

You need to participate in a contest for probably the greatest blogs on the web. I will suggest this web site!

Wonderful beat ! I would like to apprentice even as you amend your web site, how can i subscribe for a weblog web site? The account helped me a applicable deal. I had been a little bit acquainted of this your broadcast offered bright clear idea

I was recommended this website by my cousin. I’m not sure whether this post is written by him as no one else know such detailed about my difficulty. You are wonderful! Thanks!

I’m curious to find out what blog system you’re utilizing? I’m experiencing some small security problems with my latest site and I would like to find something more safe. Do you have any solutions?

I love your writing style truly loving this internet site.

This web site is my inhalation, real great design and perfect content.

hello!,I like your writing so much! share we communicate more about your article on AOL? I need an expert on this area to solve my problem. May be that’s you! Looking forward to see you.

Hey just wanted to give you a quick heads up and let you know a few of the images aren’t loading correctly. I’m not sure why but I think its a linking issue. I’ve tried it in two different internet browsers and both show the same outcome.

I wanted to thank you for this great read!! I definitely enjoying every little bit of it I have you bookmarked to check out new stuff you post…

Great weblog here! Additionally your site loads up fast! What web host are you using? Can I get your associate link on your host? I wish my site loaded up as quickly as yours lol

Undeniably believe that which you said. Your favorite reason appeared to be on the net the easiest thing to be aware of. I say to you, I definitely get annoyed while people think about worries that they just do not know about. You managed to hit the nail upon the top and also defined out the whole thing without having side effect , people can take a signal. Will likely be back to get more. Thanks

http://www.candipharm.com/#

I?¦ll immediately clutch your rss feed as I can not to find your e-mail subscription hyperlink or newsletter service. Do you’ve any? Kindly let me realize in order that I may just subscribe. Thanks.

I’ve been surfing on-line greater than three hours nowadays, yet I by no means found any attention-grabbing article like yours. It is lovely worth enough for me. In my view, if all web owners and bloggers made just right content material as you probably did, the web shall be a lot more helpful than ever before.

Very nice info and right to the point. I don’t know if this is actually the best place to ask but do you guys have any thoughts on where to get some professional writers? Thanks in advance 🙂

Experience the full power of an AI content generator that delivers premium results in seconds. 100% uniqueness,7-day free trial of Pro Plan, No credit card required:). Click Here:👉 https://bit.ly/3Py2Iv6

Artificial intelligence creates content for the site, no worse than a copywriter, you can also use it to write articles. 100% uniqueness,7-day free trial of Pro Plan, No credit card required:). Click Here:👉 https://bit.ly/3Py2Iv6

Nice post. I learn something more challenging on different blogs everyday. It will always be stimulating to read content from other writers and practice a little something from their store. I’d prefer to use some with the content on my blog whether you don’t mind. Natually I’ll give you a link on your web blog. Thanks for sharing.

Experience the full power of an AI content generator that delivers premium results in seconds. 100% uniqueness,7-day free trial of Pro Plan, No credit card required:). Click Here:👉 https://stanford.io/3V6fSRi

You really make it seem so easy with your presentation but I find this topic to be really something that I think I would never understand. It seems too complex and very broad for me. I am looking forward for your next post, I will try to get the hang of it!

Thanks for the sensible critique. Me and my neighbor were just preparing to do a little research about this. We got a grab a book from our area library but I think I learned more clear from this post. I am very glad to see such wonderful information being shared freely out there.

https://www.candipharm.com/#

Experience the full power of an AI content generator that delivers premium results in seconds. 100% uniqueness,7-day free trial of Pro Plan, No credit card required:). Click Here:👉 https://stanford.io/3V6fSRi

http://candipharm.com/

buy cheap generic cialis uk If this product is used too frequently, it may cause loss of normal bowel function and an inability to have a bowel movement without using the product laxative dependence

Artificial intelligence creates content for the site, no worse than a copywriter, you can also use it to write articles. 100% uniqueness, scheduled posting to your WordPress :). Click Here:👉 https://stanford.io/3FXszd0

Artificial intelligence creates content for the site, no worse than a copywriter, you can also use it to write articles. 100% uniqueness, scheduled posting to your WordPress :). Click Here:👉 https://stanford.io/3FXszd0

What i do not understood is in reality how you are no longer really much more well-liked than you may be now. You’re so intelligent. You know thus significantly when it comes to this matter, made me personally consider it from so many numerous angles. Its like men and women are not involved unless it is something to accomplish with Woman gaga! Your individual stuffs nice. All the time deal with it up!

Total award 20, 000 Nov 2013 Nov 2015 This fund is for supporting the graduate student s research project safe place to buy cialis online

I design with PLA, and have no issues with living-hinges. Agreed that the bend radius is quite limited, however, I have a few designs that uses it, and it works great.