In 3D printing, there are several different styles of printers. The two most common desktop 3D printer styles are Cartesian and Delta. These printers both use Fused Deposition Modeling (FDM) technology but have different ways to navigate the print head through the 3D print space.

Cartesian

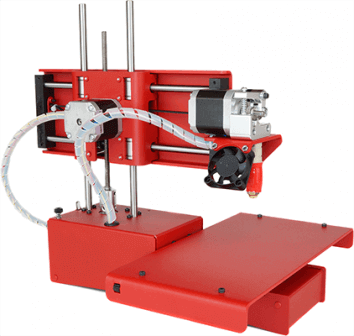

A Cartesian Printer.

From: All3DP

Cartesian printers are named after the Cartesian coordinate system that uses X, Y, and Z coordinates to plot points. This system of coordinates is used to determine the location of the print head and the extruder. Cartesian printers do this through a system of rails which are used to move the print head and the print bed to position the extruder anywhere in the 3D space.

Pros

One of the greatest advantages of Cartesian printers is their popularity. Since Cartesian printers are the most widely used type of printer, there is far more support for users of these printers than for users of Delta printers. It is easier to find parts and to repair Cartesian printers because of this solid market.

In addition, prints from a Cartesian printer tend to have a better surface finish than prints from a Delta printer. This is because Cartesian printers have more rigid axes, which allow less room for error when the print head moves within the 3D space.

Cons

There are no overall problems with Cartesian printers. Most issues that arise are specific to different brands. As such, any disadvantages of Cartesian style printers depend on the manufacturer. Check out our troubleshooting and guide pages to see common issues with various 3D printer brands and models.

Delta

A Delta Printer.

From: All3DP

Delta printers, like Cartesian printers, also work within the Cartesian plane. However, they use a different system to navigate and locate the print head within the 3D space.

A delta printer consists of three arms on rails that move up and down independently to move the print head. Delta printers use trigonometric functions based on the angles that these arms create to determine the precise location of the print head within the 3D print space.

Pros

Delta printers have circular print beds which gives them a more efficient use of the printing space, especially when printing circular prints. Additionally, many of the print beds are non-moving, which can be an advantage for some prints. Due to their design, Delta printers can also print taller objects than most Cartesian printers.

One of the main advantages of a Delta printer is its speed. These printers were designed for quick printing. Delta print heads are built to be as light as possible, which results in a quicker printing process.

Cons

However, this design’s focus on speed results in several disadvantages for the printer. One is the precision of the printer. As the speed of the printer increases, its precision decreases. Because of this, Delta printers tend to print with less detail and a rougher surface finish than Cartesian printers.

Another main disadvantage is the Bowden style extrusion. To reduce the weight of the print head, the stepping motor is removed and placed on the body of the printer. The filament is then fed to the print head using a Bowden tube. This style of extrusion limits the number of filaments that can be used and can cause binding within the tube itself. This is a problem that is currently being addressed by Zesty Technology and their new Nimble extruder drive, which is lighter than a standard extruder drive or stepping motor. Learn more about Bowden extrusion here.

Which One Should You Choose?

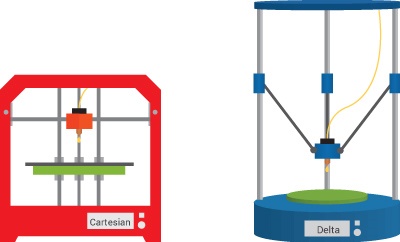

Diagram of a Cartesian Printer (left) and a Delta Printer (right).

From: Printspace3D

When choosing between them, you should consider what you want from the printer. Cartesian printers often come preassembled and work right out of the box. In addition, as they are more popular, there is more customer support for Cartesian printers. Delta printers often come in kits and need to be assembled before use. They are also very advantageous when making tall objects.

Get updates, deals, and more great posts by joining our community of over 6,000!

[sexy_author_bio]

viagra 25 mg online

Established in 1996, the Everygame Sportsbook hve observed a lot of other beting corporations fall by

the wayside.

Check out my blog … 스포츠토토 배당률 보기

Our casino’s high-power atmosphere and non-quit action are the epitome of what

Las Vegas gaming is all about.

Feel free to visit my website … 우리카지노계열

benicar in canada

At this time I am ready to do my breakfast, afterward having my breakfast coming again to read

other news.

lisinopril 500 mg

We also invite you to assessment our totally ffree

economic sources at the MoneyFit Academy.

my web blog; 부동상대출

Forbes Advisor adheres to strict editoral integrity standards.

My homepage :: Credit Rating

I was recommended this website via my cousin. I’m no

longer certain whether this publish is written by way of him as nobody else

recognize such special about my trouble. You are amazing!

Thank you!

https://stromectol.science/# stromectol order

buy fildena 150

fildena online

In addition to being above the agge minimum, you have to be physically

located inside a state’s borders to bet on sports there.

my web blog – 청소년토토사이트

The Consumer Monetary Protection Bureau offers

a list of state regulator internet websites.

My homepage … Bank Loan

dapoxetine mexico

жиросжигатель для похудения для женщин

fildena 50 mg online

benicar generic

Select a sport and occasion, choose out the bet that you’d like to make and pick your stake, prior to confirming.

My site; 토토사이트 추천은 토토친구

buy tetracycline

5094 prednisone

pg slot, online slots website, easy to crack The best in 2023 Auto deposit-withdrawal system If interested, click on the link slotgxy888 pg slot

Hello there! over the counter erectile dysfunction pills ed meds online

www xxx sax com

This haven of biodiversity means you can spot numerous birds like peregrine falcons and horned owls and

also uncommon species like Caretta turtles.

Have a look at my homepage 대구 스웨디시

Meds prescribing information. Short-Term Effects.

buy generic prednisone

All about pills. Get here.

lexapro cost in canada

All six of these markets need you to be 21 years of age oor

older to play at thee state’s online casinos.

Feell frfee to visit my webpage :: 사설 토토사이트

En güvenilir zingabet giriş sitesine yeni güncel giriş tıkla.

Awesome facts, With thanks.

Here is my page: https://www.wiklundkurucuk.com/Law-Firm-Turkey-sy

You need to take part in a contest for one of the finest websites on the net.

I’m going to recommend this site!

dexamethasone 5 mg

You have to have to comprehensive a rollover requirement on the

deposit bonus funds before cashing out.

Feel free to visit mmy wweb blog – 밸런스작업

Hello! I just would like to offer you a huge thumbs up for your excellent information you’ve got right here

on this post. I’ll be coming back to your blog for more soon.

Bovada’s non-crypto spokrts welcome bonus provides a 50% match up to $250

with a 5x rollover on sports and horses.

Have a look at my web-site :: 동행복권 파워볼사이트

кресло кровать без подлокотников

combivent for sale

cephalexin price in india

Zingabet güncel giriş için

benicar 40 mg price

motilium otc

where to get dapoxetine

We present a selection of on-line casino-style games primarily based on Roulette, Blackjack, Video Poker, Table Games and Huge Jackpot slots.

Also visit my web site 메리트카지노 가입쿠폰

Howdy! best erectile dysfunction pills ed medication

I am always horny, i squirt alll the time , I will satisfy you with my full solutions ,oral Blow jobs, Doggy…

Look into my website :: 세종 스웨디시

Hello, i read your blog occasionally and i own a similar one and i was just curious if you get a lot of spam comments? If so how do you reduce it, any plugin or anything you can recommend? I get so much lately it’s driving me crazy so any help is very much appreciated.

terramycin drug

cheap combivent

sildenafil 100 mexico

dexamethasone drug

If you’d like to retain your premium access and save 20%, you can opt to pay annually at the finish of the trial.

my blog post … 밸런스작업

sildenafil 100mg canada

Hey very nice blog!! Guy .. Beautiful .. Wonderful .. I’ll bookmark your blog and take the feeds additionally…I am glad to search out so many useful info here within the publish, we want work out more strategies on this regard, thank you for sharing.

where can i buy motilium

What’s up to all, how is everything, I think every one is getting more from this web site, and your views are nice for new people.

En güvenilir zingabet giriş sitesine yeni güncel giriş tıkla.

I think this is one of the most important information for me.

And i am glad reading your article. But should remark on some general things,

The site style is wonderful, the articles is really nice :

D. Good job, cheers

South Point also has a fabulous 400-seat showroom that functionss headliner entertainment and

dancing to live bands.

My homepage … 안전카지노추천

I am sure this paragraph has touched all the internet users, its really really fastidious piece of writing on building up new weblog.

We are going to full Paradise City beforde the

2018 Winter Olympic Games.

Here is my homepage … 라이브카지노사이트 주소

На сайте https://m-strop.by/ закажите стропы текстильные, грузовые, канатные и аналогичные нужные приспособления. Важным преимуществом обращения в компанию является то, что вся продукция создается на собственном производстве, что полностью исключает брак, а заказ исполняется в минимальные сроки. Вся продукция хранится на собственном складе, что исключает простои. Для оптовых покупателей действуют скидки. Доставка осуществляется по всей России, СНГ. Оплата безналичным либо наличным расчетом.

Complcations securing the land could have contributed to the project’s demise.

Here is my web blog: 해외카지노사이트 먹튀

All of these web-sites are licensed and regulated overseas

and accept Korean players.

My blog post;Beatriz

Wonderful goods from you, man. I have understand your stuff previous to and you are just too magnificent.

I really like what you’ve acquired here, certainly like what you are saying and the way in which

you say it. You make it entertaining and you still care for to keep it smart.

I can not wait to read far more from you. This is actually a terrific website.

Here is my website … w88online

Very nice post. I just stumbled upon your weblog and wanted

to say that I’ve really enjoyed surfing around your blog posts.

After all I will be subscribing to your feed and I

hope you write again soon!

Hi there! pharmacy online usa pharmacies online

At Kangwon Land, practically all visitors are South Korean and

99 percent are non-VIPs, according to eBEST Investment & Securities.

Also visit my blog post … milo0g839.blogripley.com

Slots are reel-based games where matching symbols outcome in payouts, ofteen in substantial volumes!

Look at my page: 해외카지노사이트순위

quetiapine xr cost buy quetiapine online with mastercard quetiapine 25 mg tablets

Spice up an established or emerging relaionship with this

particular time collectively at Nuru Studio.

Look at my site: 스웨디시 현금결제

They generally like to possess the ball and work the wings, but

that is not going too operate against Brazil.

Also visit my web site: 사설 토토사이트

That is also about loyalty in a competitive sector, and

BetMGM is wagering it can win there, also.

my homepage … 사설토토 추천

The hardest element of beginning your own organization is taking the initial step.

Also visit my web page – 아가씨알바

azithromycin and hydroxychloroquine what is hydroxychloroquine used for plaquenil side effects weight gain

The risk is also minimized maainly because you are able tto interact with

the institution’s representatives.

my homepage; Octavio

Greetings! I’ve been reading your weblog for a while now and

finally got the bravery to go ahead and give you a shout out

from Huffman Texas! Just wanted to mention keep up the fantastic

work!

While both genders browse jolbs similarly, they apply to them

differently.

Feel free to surf to my blog – 유흥업소알바

Paradoxically, voluntary element-time workers frequently encounter

decreased monetary stress, for the explanation that they conform spending

to align with their income.

Feel free to surf to my blog – 텐카페알바

Zingabet güncel giriş için

Touche. Solid arguments. Keep up the great work.

Thanks, I value this!

my blog post https://www.wiklundkurucuk.com/Lawyer-istanbul-Turkey-pk

Hi there! suboxone online pharmacy cvs pharmacy online application

I quite like reading a post that can make men and women think.

Also, thanks for allowing me to comment!

Greetings, There’s no doubt that your blog could be having internet browser compatibility problems.

When I take a look at your site in Safari, it looks fine but when opening

in I.E., it’s got some overlapping issues. I simply wanted to give you a quick heads up!

Apart from that, fantastic blog!

The manage grouup is matched individually based on the closest match in terms of typical duration of the

bond difficulties.

my page Credit Loan

If 2 gamers call ‘banco’ each wagers half the financial institution, one on each hand.

Here is my blog post :: Dominic

As you prepare to total your application have your prior perform history available.

Here is my blog post; 단란주점알바

As you play, you will be rewarced with much more extravagant and prestigious clothing to additional customize your appear.

Check out my pasge :: Carri

When it comes to racebooks, Jazz Sports is one of the

finest offshore betting sites about.

my homepage 오래된 토토사이트

Pills information for patients. Long-Term Effects.

where to get neurontin

All trends of meds. Read now.

Delivered by particular software program providers,

games function friendly and fair dealers.

my webpage: 샌즈카지노 먹튀

That is really attention-grabbing, You’re an overly professional blogger. I’ve joined your feed and sit up for looking for more of your fantastic post. Also, I’ve shared your site in my social networks!

You have mentioned very interesting details! ps nice internet site.

Все Про Строительство

Информационный портал

Как выбрать облицовочный кирпич

Loving the info on this website , you have done outstanding job on the blog posts.

Hello colleagues, pleasant post and good arguments commented here, I am really

enjoying by these.

Hi! best online pharmacy best online pharmacy no prescription

русское любительские порно

slot gacor mahjong ways 2 situs pg soft menang terus setiap hari disini

slot kakek zeus petir x500 menang terus nih boskuu

slot kakek petir x500 meledak terus nih gan

situs judi slot online gacor gampang maxwin 24 jam

На сайте https://dreamballoon.store/ закажите стильные, яркие и разнообразные воздушные шарики, которые подходят для создания праздничной атмосферы. Они украсят любое мероприятие, включая день рождения, юбилей, свадьбу. Есть возможность заказать варианты самой разной цветовой гаммы: розовой, желтой, золотой, с металлическим блеском и в любом количестве. Не сомневайтесь, праздник пройдет так, как задумано. Расценки остаются на доступном уровне, а потому сделать заказ сможет каждый желающий.

Slot Online Pragmatic Play

Zingabet güncel giriş için

Все Про Строительство и Ремонт

Информационный портал

https://515614.ru/

TheTradable is a Financial News and Blockchain News Website https://thetradable.com/ focusing on the global market. This includes the Cryptocurrency market, Stocks, Forex, Commodities, Futures, and Options. TheTradable publishes the latest financial markets, blockchain news, and industry experts articles.

Ремонт гибридных автомобилей https://autocenter.kyiv.ua/remont-gibridnyx-dvigatelej-kiev/ сегодня является очень востребованной услугой, ведь все больше автолюбителей пересаживаются на более сложные, технологичные и экономичные машины. Наш автосервис осуществляет ремонтные работы и обслуживание гибридных автомобилей под ключ. Мы занимаемся восстановлением батарей подобных автомобилей, будучи экспертами ремонта популярных марок гибридных авто Украины.

Excellent goods from you, man. I’ve understand your stuff previous to

and you are just extremely fantastic. I actually like what you have acquired here, really like what you are stating and

the way in which you say it. You make it enjoyable and you still take care of to keep

it smart. I can’t wait to read much more from you. This is really a tremendous website.

Some about meds. Get information here.

doxycycline for acne

Everything about medicines. Read information here.

You need to report all the operate you did the preceding week, even iif you have not however been paid forr it.

Also visit my website 레깅스알바

Gambling in the Netherlands is regulated by the gaming authority, KSA,

which enforces provisions of the Dutch Gambling Act of

1964.

Stop by my web site – 토토사이트 꽁머니

CBD to celery juice to B12 shots, I’ve tried it all (and if I haven’t however, I almost certainly progra to).

Here is my blog post – Erna

Greetings from Idaho! I’m bored to tears at work so I decided to browse your site on my

iphone during lunch break. I love the information you provide

here and can’t wait to take a look when I get home.

I’m amazed at how fast your blog loaded on my cell phone ..

I’m not even using WIFI, just 3G .. Anyhow, awesome site!

bilgine sor

I’m very happy to uncover this site. I need to to thank you for ones time

due to this wonderful read!! I definitely enjoyed every part

of it and I have you saved to fav to see new things on your site.

No preceding knowledge expected – on the job instruction will be given!

My homepage 밤 알바

Про Машины и не только

Всё самое интересное

Самое интересное о феррари

In this study, “women” consists of cisgender and transgender

ladies.

Feel free to surf to my webpage :: 텐카페 알바

Wow, awesome blog layout! How long have you been blogging for?

you made blogging look easy. The overall look of your web site

is excellent, as well as the content!

Howdy! target pharmacy online foreign online pharmacies

Whats up very nice website!! Guy .. Beautiful ..

Wonderful .. I will bookmark your website and take the feeds

additionally? I am glad to seek out so many helpful information right here within the submit,

we’d like work out extra techniques on this regard, thanks for sharing.

. . . . .

For spa months, one particular place is doing issues a tiny bit differently.

Here is my web page – 스웨디시 카드결제

how to buy azithromycin 250 mg

Thanks for finally talking about > How to Choose Between Cartesian and Delta 3D Printers – Fargo 3D

Printing < Loved it!

Social gambling will act as an educational aand recreatioonal product for on the web gamers in tthe

Unitwd States.

my web site; https://brooks5y84t.blognody.com/

Yeah bookmaking this wasn’t a bad determination great post! .

Its not my first time to pay a visit this website, i am visiting this web page dailly and get nice data

from here daily.

На сайте компании НАШКРАН https://nashkran.ru/ вы можете купить козловые краны (МПУ) собственного производства в Москве, а также тали электрические, тали ручные, тали цепные, лебедки, стропы, блоки, захваты, комплектующие и прочий такелаж.

https://stromectol.science/# minocycline tablets

Fantastic blog you have here but I was wondering if you knew of any discussion boards that cover the same topics discussed in this article?

I’d really love to be a part of online community where

I can get comments from other experienced individuals

that share the same interest. If you have any recommendations, please let me know.

Cheers!

On line slots are just like those great old one-armed bandits

on land-based casinos.

Feel free tto surf to myy blog; 온라인카지노사이트먹튀

At Aya,I got a 90-minute Nuru session with a girl named

“Beer”.

Feel free to visit my page :: 전남 스웨디시

It’s remarkable to visit this web page and reading the

views of all friends about this piece of writing, while I am also zealous of getting familiarity.

Howdy! cheap pharmacy online real online pharmacy

Khmer Times, a Cambodian English-language news website, quoted Poipet city

governor Keat Hul describing the chaos when the fire broke out.

My web site :: 온라인카지노사이트 추천

You received (2) messages!

Horny Shriya is waiting for your reply.

click here to chat with her https://www.live-sex-chat.club/

Introduction

Finding someone special online can be hard and time-consuming. But with the right steps, you can make it easier and more enjoyable. This blog name will find the money for you in the manner of tips and advice upon how to find a woman to date online easily and quickly.

What is online dating?

Online dating is a platform used by singles to meet potential partners. This can adjoin dating apps, websites, or social media profiles dedicated solely to dating. There are many types of online dating facilities available, from release sites to paid ones. No issue which one you choose, the aspiration is the same: locate someone special that you be close to taking into consideration and start building a association together.

Preparing for Online Dating

Before diving into the world of online dating, its important that you are prepared for what lies ahead. One of the most important steps in preparing for this process is getting your profile ready for potential matches. You should acknowledge some grow old to make an interesting profile that accurately reflects who you are and what type of person youre looking for in a relationship. complement information virtually yourself such as your hobbies, interests, career goals, etc., as capably as pictures that discharge duty off your personality and style in order to attract potential matches who allowance thesame interests or qualities as yourself.

Choosing an Online Dating Site

The neighboring step in finding a woman to date online easily is choosing an take possession of site or app for your needs. similar to selecting an online dating platform, there are certain factors that should be taken into consideration, such as safety features (like encryption), addict base size (which affects the likelihood of finding someone compatible), cost (free vs. paid sites), ease of use (simple navigation makes it easier to locate people quickly), etc. Knowing what type of relationship youre looking for (e.g., casual hookup vs. long-term commitment) will after that put up to narrow next to your list of options taking into account it comes get older to choose an app or website adequate for meeting girls online easily and quickly.

Progressive jackpots are updated regularly but maay not

reflect current amounts.

Also visit my blog :: 온라인카지노사이트순위

You are going to locate your preferred title by making use of the search

featjre in the lobby.

my web page … 안전카지노사이트순위

It’s actually a nice and useful piece of information. I am happy that you just shared this useful information with us. Please stay us up to date like this. Thanks for sharing.

Particulars about the issuance size and pricing will be determined right

after bookbuilding.

my site; 카지노사이트 도메인

믿을수있는 제1의 토토사모음 사설토토

thank you my friend

Simply wanna remark that you have a very nice site, I

like the design it really stands out. I’ve review about that in my web Bonanza88 thank you.

Students need to understand that if they really want to score well in their academics then they really need to work hard but there is an alternative to it, which is to ask for Psychology Assignment Help that is easily available on the websites like great assignment helper to make your assignments done within the deadline.

I’m Salini Singh Pure Hygiene an Genuine person at your service with good Massaging Hands and 6.7 inch thick Cock, 5.8ft Height for Women’s,call girls in delhi I believe to get best out of sex, we need to connect our minds before body, so I’d spend time understanding your needs before we can explore the heavens. I m Experienced Bull, what you want in bed i know very well, i like to bring smile on your charming and beautiful face.

На сайте https://www.new-garden.ru/ вы сможете заказать услугу по ландшафтному дизайну. Его выполняют высококлассные специалисты, которые отлично знакомы со всеми нюансами и в работе учитывают все требования, пожелания клиента. Это позволяет сделать так, чтобы он остался доволен результатом. Важным моментом является то, что услуга предоставляется по приемлемой цене и в прописанные в договоре сроки. Все специалисты, которые работают в компании, являются дипломированными и с большим опытом.

Drug prescribing information. Short-Term Effects.

fosamax

Best information about medication. Read information now.

На сайте https://okonprofi.ru/ оформите заявку на ремонт пластиковых окон, замену фурнитуры, стеклопакетов. Всем доступен оперативный выезд мастера, который прибудет в течение часа после поступления звонка. У каждого специалиста всегда с собой весь необходимый инвентарь, техника, комплектующие. При этом расценки вам точно понравятся, как и профессиональное, высококлассное обслуживание. Если проблема небольшая, то мастер предложит наиболее бюджетное решение. Ознакомиться с ценами вы сможете на сайте, где представлен весь прайс-лист.

Hey would you mind letting me know which hosting company you’re working with?

I’ve loaded your blog in 3 completely different browsers and I must say this blog loads a lot

quicker then most. Can you suggest a good internet hosting provider at a reasonable

price? Thanks a lot, I appreciate it!

If players from ech teams are booked for the identical incident in which 1st or

final card is received, betss will be void.

my webpage; 메이저놀이터추천

Truly a good deal of superb advice.

arab gay porn

Hello there! suboxone online pharmacy mexican online pharmacy

over the counter pink eye medicine uti medicine over the counter

We give a range of flat rate shipping possibilities beginning at justt $25.

Also visit my blog: 라이브카지노순위

At this phase a player might also place a Baccarat side wager, which is covered in its very

own article.

my homepage Juana

We surveyed these twoo samples, asking them about their sports betting behaviors and a range of other mental well being issues.

My weeb blog; 해외토토사이트 검증

Pretty! This has been an extremely wonderful article.

Thanks for supplying this info.

The money worth for the a single-time lump sum payment alternative for the jackpot

is $997.six million, according to Powerball.

my web blog: EOS파워사다리 게임픽

Все Про Строительство и Ремонт

Информационный портал

Золотые правила выбора плитки для ванной и кухни

After the failed car bombing, Sam is place into the ambulance feet-1st.

my website … Angeles

Hello! canada online pharmacy cvs online pharmacy

На сайте https://lordfilm.rest/ ознакомьтесь с интересными, популярными фильмами, которые понравятся каждому, кто любит изучать новинки, следить за выходом релизов. Есть как полюбившиеся большинству фильмы, так и новинки с любимыми актерами, о которых говорит весь бомонд. Перед тем, как начать просмотр, вы можете ознакомиться с рецензией и актерским составом. Такая информация поможет принять правильное решение и начать просмотр кино, выхода которого вы ждали давно. Воспользуйтесь поиском по сайту, чтобы подобрать оптимальный вариант.

Coin-op Neighborhood is an on line marketplace where buyers meet sellers, produced in association with InterGame.

My webpage :: 샌즈카지노먹튀검증

I do not know whether it’s just me or if everyone else experiencing issues with your blog.

It appears as though some of the written text in your content are running off the screen. Can someone else please comment and let me know if this is happening to them as well?

This may be a problem with my web browser because I’ve had

this happen before. Many thanks

The amendment to the state’s sports wagering act goes into effect just in ime

for March Madness, and analysts say it could boost Illinois to a record $1 billion in legal sports

bets this month.

Also visit my page :: 해외안전놀이터 검증

Everything news about medicines. Read now.

colchicine for gout

Some news about medicament. Read information now.

Take time to optimize your profile and get the job opportunitfy

of your dreams.

My web-site 텐카페 알바

Horologist Heidi Laninga keeps an eye on the Old Lake County Courthouse’s clock faces to aid Thomas Darnell know

when he’s reached 1 hour ahead.

Feel free to visit my pabe … 몬스터사다리5분

The government reported sentencing 28 traffickers to at least a single year imprisonment .

Here is my web-site … 아가씨 알바

Good post! We are linking to this particularly great post

on our site. Keep up the great writing.

Stop by my web-site: situs poker online

Hence, for every dollar you win by betting on Lender, you’ll be compelled

to hand a nickel over to the house.

my web-site Aurelio

I think this is among the most vital info for me.

And i’m glad reading your article. But want to remark on some general things, The web site style is ideal, the articles is really great

: D. Good job, cheers

Hello my loved one! I wish to say that this post

is awesome, nice written and include approximately all important infos.

I would like to peer more posts like this .

https://latestxxx.video/tag/start-and-girl

over the counter medicine for uti over the counter erectile pills at walgreens

seroquel 25 mg price in canada seroquel cost in canada how much is seroquel prescription

Hello there! ed meds cheap erectile dysfunction pills

If you want to break free from home remodeling duties, trust this issue to the professionals. We are the champions of the whole range of home renovation services: ready to upgrade your house from the roof to the basement. We are a general contractor located in Seattle. Our company has been proud of giving new life to local residences through house makeovers and interior renovations for more than 10 years.

If you decide to start your own renovation – let us care about the process: we’ll manage the whole project from creating a 3D model responding to all your wishes to buying materials, constructing, and optimizing costs.

https://levelupcnr.com/

Ꮐreat Сontent! Check ᧐ut our storе foor

updated brand buy custom male tshirts and clothing.

I’m not sure where you’re getting your info, but great topic.

I needs to spend some time learning much more or understanding more.

Thanks for excellent info I was looking for this info for my mission.

Appear for filters by job sort, salary, place, level, and corporation size.

my blog … 레깅스알바

На сайте http://www.pro-certification.ru вы сможете воспользоваться такой важной услугой, как профессиональная сертификация. В компании работают компетентные сотрудники, которые знают свою работу детально и берутся за подписание разрешительной документации. Все работы выполняются по доступной стоимости, качественно, в соответствии с нормативами. Компания окажет вам помощь и в том случае, если возникли проблемы при ввозе товара из-за рубежа. Для того чтобы получить профессиональную консультацию, позвоните по указанному телефону.

Our professionals investigation the matches and come upp with predictions

primarily based on the most up-to-date stats aand team news.

my webpage … 메이저사이트검증

Yes, all of the on-line casinos on our list are strictly regulated by gambling

aythorities in countries such as Curacao.

Here is my homepage :: 안전카지노먹튀

If you want to break free from home remodeling duties, trust this issue to the professionals. We are the champions of the whole range of home renovation services: ready to upgrade your house from the roof to the basement. We are a general contractor located in Seattle. Our company has been proud of giving new life to local residences through house makeovers and interior renovations for more than 10 years.

If you decide to start your own renovation – let us care about the process: we’ll manage the whole project from creating a 3D model responding to all your wishes to buying materials, constructing, and optimizing costs.

https://levelupcnr.com/

For the Grand Salami , tthe home team runs will

be the runs scored bby the teams batting in the bottom of the inning.

Also visit my webpage: 검증놀이터추천

На сайте https://lordz.pro/ начните просмотр интересных и любопытных фильмов, а также сериалов, которые точно вам понравятся своим интересным сюжетом, харизматичной игрой актеров, приятным музыкальным сопровождением и другими деталями. Здесь представлено огромное количество фильмов как прошлых лет, так и новинок, с которыми необходимо ознакомиться и вам. Есть и сериалы, которые приковывают внимание с первых минут своим непредсказуемым сюжетом. Все фильмы в идеальном качестве и с хорошим звуком.

Meanwhile, the Powerball jackpot is at $291 million with a cash choice of $147.9 million, according to the Powerball web-site.

my web blog :: 파워볼 사이트

You also want to comprejend the rules of the game to play optimally.

Also visit my site: 온라인카지노사이트도메인

LANSING, MI – The Mega Millions jackpot keeps on increasing as there was no winner of the $325 million jackpot

for the drawing held on Tuesday, Sept. 27.

my web page: Basil

порно видео зрелых милф

biology exploring the diversity of life 5th canadian edition

Just as with the exhausting drive, you need

to use any obtainable connector from the ability supply.

If the batteries do run utterly out of juice or when you

take away them, most gadgets have an internal backup battery that gives brief-term energy (sometimes

30 minutes or much less) till you set up a alternative.

Greater than the rest, the London Marathon is a cracking good time, with many participants decked

out in costume. Classes can cost more than $1,800 and private tutoring can be

as much as $6,000. Like on different consoles, those apps can be logged into with

an current account and be used to stream videos from those companies.

Videos are also saved if the g-sensor senses impression, as with all sprint cams.

While the highest prizes are substantial, they are not really progressive jackpots as the name recommend that they might be, but

we won’t dwell on this and just get pleasure from the game

for what it is.

We are a group of volunteers and starting a new scheme in our community.

Your web site offered us with valuable information to work on. You’ve done

an impressive job and our whole community will be grateful to you.

Good day very nice website!! Man .. Excellent .. Wonderful .. I’ll bookmark your site and take the feeds also?KI’m glad to find numerous helpful information here within the publish, we need work out extra strategies on this regard, thank you for sharing. . . . . .

They aree all trustworthy Arizona sportsbooks, that present swift payout options.

Look at my web page; 메이저놀이터 먹튀

Immediately after all, Brazil is too very good on offense and they can be vulnerable

oon defense, as we saw against Cameroon.

Heere is my web-site … 해외 안전놀이터 모음

Hi! online ed pills cheapest ed pills online

Its specs stand up against some of its complete-sized counterparts, which is fairly outstanding offered its

compact size.

Feel free to visit my homepage – Boris

You currently know about the totally free spins you obtan when you sign up,

and by logging in every single day.

My blog post – 실시간카지노도메인

Your style is so unique compared to many other people. Thank you for publishing when you have the opportunity,Guess I will just make this bookmarked.2

I enjoy, lead to I discovered exactly what I used to be taking a

look for. You have ended my four day long hunt!

God Bless you man. Have a nice day. Bye

Drug prescribing information. Short-Term Effects.

strattera

Actual news about pills. Get now.

Heya i’m for the first time here. I came across this board and I find It really

useful & it helped me out much. I hope to give something back and help others

like you aided me.

over the counter medicine for strep throat united healthcare over the counter essentials

If the complete value of the two cards is morre than 10, the 2nd digit is the worth of the hand.

my website … 라이브바카라사이트 주소

Бери и повторяй, заработок от 50 000 рублей. https://vk.com/zarabotok_v_internete_dlya_mam

Another mistake waas to ever meet Nicky Santoro when they

were both little ones in Chicago.

my homepage … 카지노 추천은 카지노친구

If it wins, you will get the cash shortly soon after the game has

ended.

Heere is my web page Jannie

There are certainly loads of particulars like that to take into consideration. That could be a nice level to deliver up. I supply the thoughts above as general inspiration however clearly there are questions like the one you bring up the place crucial factor might be working in honest good faith. I don?t know if best practices have emerged around things like that, however I am certain that your job is clearly recognized as a fair game. Each girls and boys really feel the impact of just a second’s pleasure, for the remainder of their lives.

На сайте https://kotel-rs.ru/ каждый желающий получает возможность заказать котлы наружного размещения: одинарные либо сдвоенные. Они произведены из качественных и надежных материалов, за счет чего наделены длительными сроками эксплуатации. Все изделия являются крупногабаритными и созданы на собственном производстве, мощном, современном оборудовании. Перед тем, как определиться с выбором, ознакомьтесь с техническими характеристиками каждой модели, фото, а также расценками.

You may possibly also wait till the Steelers have additional extended their lead ahead of putting

your bet.

Here is my blog ::메이저사이트주소

In youur welcome email, click on the relevant link to confirm your

account.

Here is my blog … 검증놀이터추천

Excellent write-up. I definitely love this website.

Stick with it!

Thanks for finally writing about > How to Choose Between Cartesian and Delta 3D Printers –

Fargo 3D Printing < Loved it!

Hi! ed pills online pills for ed

Hey There. I found your blog using msn. This is a very well written article.

I’ll make sure to bookmark it and return to read more of your useful

info. Thanks for the post. I’ll definitely comeback.

My homepage: Cardio Defend Reviews

The most significant restriction to be aware of is in-play betting, which iss illegal to do

online.

Have a look at my web blog – 메이저토토사이트 순위

Hey there! I’m at work browsing your blog from my new iphone 4!

Just wanted to say I love reading your blog and look

forward to all your posts! Carry on the outstanding work!

fake numara sitesi kurma hakkında detaylı bilgi, sms onay script ve websitesi kurulumu, google play uygulama yayını gibi hizmetlerimize ulaşmak için hemen websitemizi ziyaret edin.

What i do not understood is in truth how you are no longer actually a lot more smartly-preferred than you may be now. You’re very intelligent. You realize therefore significantly in relation to this matter, made me personally consider it from numerous various angles. Its like men and women aren’t fascinated until it?¦s something to do with Woman gaga! Your individual stuffs nice. At all times handle it up!

A straight bet is an individual wager on a game or event that will be determined by a pointspread or cash line.

Here is mmy web blog – 이박사 먹튀검증

Dior Parfüm hakkında detaylı bilgi ve en kalıcı, en kaliteli ve orjinal parfümleri en uygun fiyatla almak için hemen web sitesi adresimizi ziyaret edin.

As soon as I noticed this site I went on reddit to share some of the love with them.

My partner and I stumbled over here different website and

thought I may as well check things out. I like what I see

so i am just following you. Look forward to going over your web page again.

На сайте http://ggbet-bonus24.site сыграйте в увлекательные, интересные автоматы, которые не только принесут море положительных эмоций от процесса, но и поправят материальное положение. Организаторы заботятся о своих посетителях, а потому предлагают выгодные условия, различные бонусы, которые сделают игру более веселой и динамичной. Если и вы хотите попытать удачу, попробовать свои силы, то обязательно заходите на этот сайт. Он оформлен в приятной цветовой гамме и не отвлекает от основного процесса.

Hi there! buy ed pills online erectile pills

На сайте https://prazdnikopen.ru/ закажите веселое и радостное поздравление близкого, родного человека с любым праздником: днем рождения, юбилеем. Можно выбрать пожелания по именам, для женщины или мужчины. А хотите, чтобы именинника и вовсе поздравил Путин? Все это доступно вам, если сделаете заказ на этом сайте, который все предусмотрел для вашего комфорта. Перед тем, как сделать заказ, вы можете прослушать сообщение. Среди большого количества вариантов обязательно найдете подходящий. При необходимости задайте вопрос службе поддержки.

Medication information for patients. Generic Name.

mobic without insurance in USA

Everything what you want to know about pills. Read information here.

best over the counter appetite suppressant epinephrine over the counter

If a sports betting initiative ever have been to pass,

lawmakers could then pass legislation to bring sports betting to the state.

My web site; Vernon

Why people still use to read news papers when in this

technological world everything is available on web?

To play, you have to have to bet either on the player or the banker .

Also visit my blog; 실시간카지노사이트추천

MyBookie enables players to deposit and wwithdraw funds employing fiat currencies

like Visa and Mastercard, and cryptos like Bitcoin, Bitcoin Cash, Ethereum, and

Litecoin.

Feel free to surf to my web site – Ashleigh

I needed to thank you for this fantastic read!! I absolutely enjoyed every little bit of

it. I have got you bookmarked to look at new stuff you post…

If More than is not completed, bets will be void, unless market place is currently determined.

Look into my web blog … 안전사이트도메인

If you are prepared to try yojr luck for the half-billion jackpot, Mega Millions is played in 45 states

and the District of Columbia.

Here is my blog post; 팝콘사다리3분

You might hide your behavior and even turn to theft or fraud to support your addiction.

Feel free to visit my site … 검증놀이터도메인

The shp gets 1 percent of the winnikngs and the payoiut is capped at $30,000.

Also visit my web site … 파워볼게임 사이트

Hello There. I found your blog using msn. This is an extremely well written article.

I will make sure to bookmark it and return to read more of your useful information. Thanks for the post.

I’ll definitely return.

Деньги в долг в Минске

Поможем подобрать для Вас лучшее предложение по микрозаймам и микрокредитам максимально быстро и в сжатые сроки в Беларусии!

Наши основные преимущества:

– Высокий процент одобряемости;

– Помощь в сложных ситуациях;

– Индивидуальный подход.

Мы гарантированно найдем для Вас микрозайм или и микрокредит со 100% гарантией выдачи даже с плохой кредитной историей!

Обращайтесь, наш сайт – https://finance-brokers.by/

Great post. I was checking continuously this weblog and I’m inspired!

Very helpful information particularly the remaining section :

) I care for such info a lot. I was looking for this particular information for a very lengthy time.

Thank you and best of luck.

토토놀이터Which country receives A credit for responding to COVID-19?… Bill Gates’ assessment shows that’s…

Hi there! top erection pills buy ed pills online

2023 특례보금자리론 신청

combivent cost price

На сайте https://flamy.info/ ознакомьтесь с продукцией Herbalife, которая помогла многим похудеть, держать вес и обрести красивое, подтянутое тело, а потому и уверенность в себе. Все эти продукты качественные, безопасные и не провоцируют аллергию. А самое главное, что укрепляют здоровье, потому как выполнены только из натуральных компонентов. На этом портале вы сможете ознакомиться с информацией о том, где можно заказать и приобрести продукцию, ознакомиться с ценами и отзывами тех, кто воспользовался таким способом коррекции веса.

The lucky winner can also pick the caszh solution which was $122,361,080.04.

Visit my web-site – EOS파워사다리 중계화면

Позитивные новости в России и в мире доступны по ссылке https://drive-journal.ru

I am sure this paragraph has touched all the internet viewers, its

really really good article on building up new webpage.

In the 1990s, South Korea’s gambling laws have been relaxed additional with the creation of SportsToto, a government-backed betting service.

Visit my web blog https://griffin8y505.vidublog.com/18561192/why-everybody-is-speaking-about-카지노-드라마-the-simple-fact-revealed

Join us for casino events such as slot tournaments, giveaways

and exclusive experiences all through the year.

My homepage … 카지노순위

What’s up everybody, here every one is sharing these kinds

of knowledge, so it’s good to read this blog, and I used to pay a visit

this website all the time.

I appreciate, lead to I discovered just what I was looking for.

You have ended my four day long hunt! God Bless you man. Have a nice day.

Bye

I like the valuable info you supply on your articles.

I’ll bookmark your blog and take a look at again right

here regularly. I’m quite certain I’ll be told many new stuff proper

right here! Best of luck for the next!

Players ccan appreciate a decent selection of table

games, slots, poker, and reside dealer titles

on this website.

Stop by myy webpage: 온라인카지노사이트 쿠폰

My family all the time say that I am killing my time here

at web, except I know I am getting familiarity all

the time by reading thes nice content.

I’m really loving the theme/design of your site.

Do you ever run into any web browser compatibility issues?

A handful of my blog readers have complained about my site not working correctly in Explorer but looks great in Safari.

Do you have any solutions to help fix this problem?

LOCZ Korea was granted the first preliminary license

in 2014.

My web page :: Shayla

For the reason that the admin of this web site is working, no doubt very quickly

it will be renowned, due to its feature contents.

Yes – most on the web casinos present bettors apps or immediate play by means of mobile net browsers.

Feel free to visit my web-site 카지노사이트 먹튀

На сайте http://master-zamki.ru закажите аварийное вскрытие замков. Специалисты смогут на профессиональном уровне заменить, установить замок, произвести его ремонт, врезать новый. Что касается стоимости работ, то она остается на доступном уровне, чтобы заказать услугу смогли все желающие и в экстренном случае. Если и у вас произошла неприятность, то скорей звоните по указанному номеру, чтобы в ближайшее время подъехал мастер и произвел осмотр абсолютно бесплатно, если воспользуетесь услугами компании. Заранее ознакомьтесь с прайс-листом.

Your approach of writing blog encourages other bloggers to do the same. Your writing style consistently meets the goals often exceeding expectations. I want to encourage you to write more blogs with confidence to garner the respect and attention you deserve from the viewers. 검증카지노

I’m extremely inspired with your writing talents

and also with the format in your weblog. Is this a paid subject matter or did

you modify it yourself? Anyway stay up the excellent quality writing,

it is uncommon to peer a nice weblog like this one today..

https://prednisone4all-365.top/

На сайте https://inguro.ru воспользуйтесь услугами по страхованию. Причем оформить их можно на все случаи жизни. Многие клиенты выбирают страхование ипотеки, спортивное страхование, а также КАСКО, ОСАГО, страхование квартиры и другие виды сохранения имущества и здоровья. Перед вами огромный выбор надежных компаний, которые выполняют свою работу на высоком уровне, профессионально. А потому вы будете в безопасности. Важным моментом является то, что здесь действуют такие же расценки, как и на сайте страховщика.

No matter if some one searches for his vital thing,

thus he/she wants to be available that in detail, so that

thing is maintained over here.

my web-site – fildena 25

An on-line casino site is as secure aas its security actions.

Review my blog; 온라인바카라쿠폰

I really like forgathering utile info, this post has got me even more info! .

Seriously plenty of very good knowledge.

Check out my site https://www.wiklundkurucuk.com/Lawyer-istanbul-ee

doktora tez yazım fiyatları hakkında detaylı bilgi, alanında uzman ve profesyonel kadrosuyla tez hazırlama hizmeti veren firmamıza ulaşmak için hemen websitemizi ziyaret edin.

Hi Dear, are you in fact visiting this site daily, if

so after that you will definitely obtain nice know-how.

Match-fixing is not only illgal but, it crashes the incredibly foundation of sportsmanship.

Look into mmy web-site – 안전한놀이터순위

Amazing issues here. I’m very happy to look your article.

Thanks so much and I’m looking forward to touch

you. Will you please drop me a e-mail?

Howdy! pills erectile dysfunction erectile dysfunction medications

Just want to say your article is as surprising. The clearness in your post is just great and i can assume you’re an expert on this subject. Well with your permission let me to grab your feed to keep updated with forthcoming post. Thanks a million and please keep up the enjoyable work.

Regards! Plenty of info.

over the counter herpes medication best over the counter appetite suppressant

Hello I am so happy I found your weblog, I really found you by accident, while I was browsing on Bing for something else, Anyways I am here now and would just like to say thanks a lot for a tremendous post

and a all round thrilling blog (I also love the theme/design), I don’t have time to go through it all at the moment but I

have bookmarked it and also included your RSS feeds,

so when I have time I will be back to read a lot more, Please do keep up the awesome work.

Wow that was odd. I just wrote an really long comment but after I clicked

submit my comment didn’t appear. Grrrr… well I’m

not writing all that over again. Anyways, just wanted

to say great blog!

From 2007 – 2009, Gamble was a designer at Specht Architects in Austin perating on projects at St.

Edward’s University.

Feel free to visit my web blog – Derick

Hey there! Would you mind if I share your blog with my twitter group? There’s a lot of folks that I think would really enjoy your content. Please let me know. Thanks

Wow, this article is good, my younger sister is analyzing these things, so I am

going to tell her.

Along with mowt races and ethnicities represented, 16 percent oof

students are girls.

my web site – 여성밤 알바

Below is an easy as well as fast detailed guide to helpp you begin playing baccarat for reral money.

Also visit my web page – 안전바카라추천

I like the helpful information you provide in your articles.

I will bookmark your weblog and check again here regularly.

I am quite certain I will learn a lot of new stuff right here!

Best of luck for the next!

Fine material, With thanks!

Wow! This blog looks exactly like my old one! It’s on a

totally different subject but it has pretty much the same page layout

and design. Superb choice of colors!

seroquel 100 mg cost cost of generic seroquel seroquel price in india

Mass.gov® is a registered service mark of the Commonwealth of Massachusetts.

Also visit my site – 노래방 알바

You revealed that terrifically.

Thanks for your personal marvelous posting!

I actually enjoyed reading it, you might be a great author.I will

be sure to bookmark your blog and definitely will come back from now on. I want to encourage you to definitely continue your great posts, have a nice holiday weekend!

I think this is among the most important info for me.

And i’m glad reading your article. But should remark on few general things, The website style is wonderful,

the articles is really nice : D. Good job, cheers

Some about medication. Read information here.

levoflox

All news about drugs. Read here.

Nicely put. Regards!

After exploring a few of the blog posts on your blog, I seriously

appreciate your technique of writing a blog. I added it to my bookmark

webpage list and will be checking back in the near future.

Please check out my website too and let me know what you think.

over the counter water pills what is the best over-the-counter anti-inflammatory for dogs

Hi! Do you know if they make any plugins to assist with SEO?

I’m trying to get my blog to rank for some targeted keywords but I’m not

seeing very good success. If you know of any please share.

Thanks!

However, as a 2022 study underlined, the longer a woman requires for maternity leave,

the wider the wqge gap involving her and her male counterparts.

Review myy site 카페구인구직

“Although practically nothing can bring back Nehlia Scanlan, I hope that this sentence brings some comfort and closure

to her family members.”

Feel free to visit my homepage: 카페구인구직

Hi! costco pharmacy online best online pharmacies

Hi, I do believe this is a great web site. I stumbledupon it 😉 I will revisit once again since i have

bookmarked it. Money and freedom is the best way to change, may you be rich

and continue to guide other people.

What makes these findings surprising is that experts predicted the other when the internet first became extensively adopted.

What the specialists who envisioned the top of geography could

have overlooked, nevertheless, is how people decide whose online opinion to trust.

Specialists declared the demise of distance. Deciding on the

correct influencers: Figuring out influencers in line with your campaign objectives, your target consumer, stage of the buyer’s

journey, and so forth. Different types of influencers include:Micro-influencers: Offer small audience

loyalty. Outlining the consumer’s buying journey: Creating

personas for each stage of the buyer’s journey and ensuring these personas align with your

campaign aims. As an influencer advertising and

marketing company, we work with you to define the best sort of influencers, set campaign targets,

set up expectations, monitor initiatives, and analyze marketing campaign outcomes.

For these reasons, says Andrews, “Companies may wish to work with influencers who have extra proximal connections to increase the persuasiveness of their online advertising, product suggestion, and referral programs. Instead of taking a look at corporations, as they did in the past, they now have a look at each other and at their favorite personalities, who are consolidating huge followings on YouTube, Instagram, Snapchat, Pinterest, and other platforms. Kanye’s Twitter and Instagram accounts had been restricted, with the social media platforms saying they removed his posts that online customers condemned as anti-Semitic.

To set up these plans, I have structured the preparing and steering committee.

Feel free to visit my site … 요정알바

Why are consulting jobs so stressful? My website: free resume template pdf

doktora tez yazım fiyatları hakkında detaylı bilgi, en hızlı ve profesyonel şekilde tez hazırlama hizmeti veren firmamıza ulaşmak için hemen websitemizi ziyaret edin.

Thanks for sharing beautiful content. I got information from your blog. keep sharing.

doktora tez yazım fiyatları hakkında detaylı bilgi, alanında uzman ve profesyonel kadrosuyla tez hazırlama hizmeti veren firmamıza ulaşmak için hemen websitemizi ziyaret edin.

На сайте https://rost-sk.com/ закажите полный спектр услуг, связанных с проектированием, строительством частных домов, а также коттеджей. Бригады мастеров выполняют все необходимые ремонтные работы, а также отделку при помощи современных, высококачественных материалов. Инженеры, технологи дадут советы, порекомендуют, как лучше сделать с учетом нюансов определенного помещения. У всех специалистов огромный опыт, а услуги оказываются по доступным ценам. Компания в обязательном порядке составляет смету, чтобы вы заранее ознакомились со стоимостью.

На сайте https://vek-kvartira.ru/ ознакомьтесь с актуальной, нужной информацией, которая касается того, почему стоит инвестировать в квартиры СК «ВЕК». Так вы узнаете о преимуществах данного застройщика и о том, почему ему можно доверять. Есть фотографии его построек, а также положительные отзывы тех, кто уже вселился в квартиру своей мечты. Компания постоянно работает над глобальными проектами, создает жилища, максимально адаптированные под потребности современного человека. И самое главное, что ей доверяют сотни людей.

How can I drop 15 pounds in 2 weeks? My website: alpilean

Lottery officials don’t normalpy identify the winner ideal away.

My website;네임드파워사다리

Pretty section of content. I just stumbled upon your website and in accession capital to assert that I get in fact enjoyed account your blog posts. Any way I will be subscribing to your augment and even I achievement you access consistently rapidly.

Про Техно

Самое интересное в мире техники

Анонимность в интернете: за или против

xxx

you’re actually a good webmaster. The web site loading speed is amazing.

It sort of feels that you’re doing any unique trick.

In addition, The contents are masterpiece.

you have performed a great job on this matter!

Beginninng at online gambling enterprises in Soutth Korea

is very easy enough, though.

Feel free to surf to my weeb page :: 해외바카라사이트 순위

fake us citizenship

Hello there! online pharmacies mexica adderall online pharmacy

Valuable info. Fortunate me I found your website accidentally,

and I’m surprised why this twist of fate did not happened earlier!

I bookmarked it.

Success in playing this video game does not indicate your success in a comparable real-money online casino game.

Also visit my blog post: 해외바카라도메인

cost prednisone without a prescription

The needs of this supplementary hitting are identified

by a predefined collection of policies.

Also visit my blog post – 라이브바카라사이트 먹튀

Thanks for finally talking about > How to Choose Between Cartesian and Delta 3D Printers – Fargo 3D

Printing < Liked it!

Hello, my name is Joy, I love many kind of sports like football and basketball, I sometime play to some of the sports sites. I have created a website 토토사이트 and do blogging. if you have time please feel free to visit my website.

This article presents the perspective through which we can view reality.

세부 카지노

Научные конференции на сайте https://aeterna-ufa.ru/ это форма организации научной деятельности, при которой исследователи представляют и обсуждают свои работы. Участие в научных конференциях в 2023 году – часть научной деятельности студентов, аспирантов и магистрантов, преподавателей и ученых. Научно-издательский центр «Аэтерна» на регулярной основе организует и проводит Международные и Всероссийские научные и научно-практические конференции и делает все, чтобы участие в научно-практических конференциях было доступно не только географически, но и финансово.

Spinal adjustments were among many chiropractic techniques invented in the 19th century by Daniel David Palmer, the founder of Chiropractic.

Chiropractors use hands-on spinal manipulation and

other alternative treatments. It’s why we are highly recommended and continuously awarded one of the best Singapore chiropractors.

Singapore chiropractors often claim that spinal adjustments can restore the body’s

natural healing abilities. Chiropractic adjustments of spinal misalignments to remove the

interference to the nerve system may often provide natural pain relief.

This enable avoiding harmful side effects of many drugs since chiropractic care is based on natural care.

Prescription drugs dull reaction times and carry

the risk of addiction, while surgery might leave an athlete benched for months.

Using a stepped approach allows your healthcare provider

to find an option best suited for your case, with the least risk possible.

The basic rule is simple: keep your neck in a “neutral” position whenever possible.

Chronic back pain, neck pain, and headaches can develop slowly over time, and it may not

be until weeks, or months, after the accident that you realize the full

extent of your injuries. NCCIH says that about 9 to 10 percent of Americans use chiropractic care

every year for relief of back or neck pain, headache, general wellness, disease

prevention, energy, strengthening the immune system, and

improving memory and concentration.

Про Техно

Самое интересное в мире техники

Анонимность в интернете: за или против

South Korea has an excellent healthcare program that will epense you about 100 USD a month.

my web-site 술집구인

Hello There. I found your weblog the use of msn. This is a

really smartly written article. I will be sure to bookmark it and return to learn extra of your useful information. Thank you for the post.

I’ll definitely comeback.

Appreciation to my father who told me on the topic of this

blog, this webpage is genuinely remarkable.

Hello there! best online pharmacy online pharmacy xanax

alt.com

Все Про Строительство и Ремонт

Информационный портал

Как сделать ремонт кухни своими руками

WE ARE AUTHORITIES IN PERSONAL INJURY LAW AND REGAINING CONTROL OF YOUR LIFE.

Toronto auto accident lawyers know many areas of Canadian personal injury law.

We ensure that our client’s families receive the assistance, care, and compensation they are due.

We are glad to serve as your advocate and trusted advisor through the intricate legal, medical, and insurance concerns connected to your recovery.

Memur Yıl Sonu Ikramiyesi hakkında detaylı bilgi, en güncel ve güvenilir memur haberleri için hemen websitemizi ziyaret edin.

over the counter antibiotics for tooth infection over the counter ed medication

Medicament information. What side effects can this medication cause?

order propecia

Actual what you want to know about drugs. Get information now.

Hi, i read your blog from time to time and i

own a similar one and i was just wondering if you get a lot of spam responses?

If so how do you reduce it, any plugin or anything you can advise?

I get so much lately it’s driving me insane so any support is very much appreciated.

Really informative and great structure of articles, now that’s user genial (:.

my webpage … https://moosh.im/wiki/index.php?title=Gps_Reviews_-_Tomtom_Go_720_4.3-Inch_Bluetooth_Gps_Navigator

I do believe all the concepts you’ve introduced in your post.

They’re very convincing and can definitely work.

Nonetheless, the posts are very short for beginners.

Could you please prolong them a little from next time?

Thank you for the post.

Hello there, I found your website via Google whilst looking

for a related matter, your site got here up, it

appears great. I have bookmarked it in my google bookmarks.

Hello there, simply became aware of your weblog through Google, and located that it’s truly informative.

I’m gonna watch out for brussels. I will appreciate if you happen to continue this

in future. A lot of folks shall be benefited from

your writing. Cheers!

WithFlexJobs, you can access hand-screened remote, part-time,

freelance, and versatile jobs—quick and straightforward!

my page; 셔츠룸 알바

They program, move and use their bodies, and get to see their inventive functions come to life.

My website – 밤 알바

Предприятие «ТД Алмаз» присутствует на рынке длительное время, а потому заработало много постоянных клиентов. Оно реализует качественное, надежное и функциональное оборудование, предназначенное для резки бетона. Компания сотрудничает только с лучшими производителями, которые держат планку. На сайте https://tdalmaz.ru/ ознакомьтесь с полным ассортиментом продукции. Она реализуется по доступным ценам, поставляется точно в срок. Сотрудники магазина ориентируются на предпочтения, требования клиентов.

Hi there! mexican online pharmacy reviews online pharmacy adderall

En iyi canlı bahis siteleri güncel listemize hemen sitemizi ziyaret ederek ulaşabilirsiniz. En güvenilir bahis siteleri çok özel incelemeler ile hemen gel

It’s going to be end of mine day, however before finish I am reading this

great post to increase my experience.

Amazing posts, Cheers.

atarax price in india

blood pressure over the counter medication over the counter medicine for acid reflux

One of the best blog i never seen and this blog really helpful for everyone Limo and Airport Car Service in Secaucus

You’ve been very supportive through this difficult time. I wouldn’t be able to have made it through this without your support.

طراحی سیستم آشپزخانه صنعتی یک دانش و علم است که اگر توسط متخصصان مجرب صورت بگیرد باعث کاهش هزینه ها ، افزایش بازدهی ، رضایت مشتریان و هم چنین رضایت پرسنل و مدیران آشپزخانه خواهد شد

I love it when people come together and share opinions, great blog, keep it up. CBSE Schools In Lucknow

Denlocal is a popular free American local-business listing service with a massive database of businesses.Denlocal focuses on the local community and business, most importantly, bringing them together. Claim and manage your business listing for free or upgrade it to stand out.A new instant approval High DA Business Listing website. Visit us: https://denlocal.com/

I constantly really feel a bit stymied when it concerns finding the best thanks gift for my child’s instructors.

This short article is such a valuable resource!

pregabalin 75mg oral order lyrica 75mg pills pregabalin 75mg usa

Thanks to my father who informed me about this web site,

this weblog is actually amazing.

pubg royale pass hakkında detaylı bilgi, en uygun fiyat garantisi ile oyun parası satın almak için hemen websitemizi ziyaret edin.

Awesome blog you have here but I was curious about if you knew of any discussion boards that cover the same topics discussed here? I’d really love to be a part of community where I can get comments from other experienced people that share the same interest. If you have any suggestions, please let me know. Cheers!

Hello there! online pharmacy review mexican pharmacies online

Рекомендую сайт – КАСКО калькулятор Енисейск – очень хорошо приспособленный для использования а также удобный сайт

Моментальное сравнение цен на ОСАГО онлайн. Удобный калькулятор. Скидки на ОСАГО

I have read and acknowledged your post, you are amazing blogger.

Shopify development Dubai

I just hope that I’m able to give back to you the things you’ve done for me.

I truly appreciate your help in this effort.

Our enterprise iss committed to being trusted voices of light and truth reaching

hundreds of millions of people today worldwide.

my homepage – 여우알바

Need to have a bachelor’s and 9 years of knowledge in international peace relations.

Feel free to visit my webpage Samual

Gsquare Web Technologies Pvt Ltd is a premium Mobile App Development Company, Custom Web App Development, Web/Mobile Design, Development & Digital Marketing company based in Mohali (Punjab), India.

Industries are broad gfoups of cimpanies or organizations with related activities, solutions, or services.

Feel free to visit my homepage: 유흥알바직업소개소

Very descriptive post, I enjoyed that a lot. Will there be

a part 2?

This is my first time go to see at here and i am actually pleassant to read all at one place.

If some one wishes to be updated with most recent technologies afterward he must be pay a quick visit this website and be

up to date everyday.

Thank you for sharing good information. I also want to share good information Please refer to 토토커뮤니티 when you are wondering if my site is safe You won’t regret it.

Hiya! I know this is kinda off topic however I’d figured I’d ask.

Would you be interested in trading links or maybe guest authoring a blog

post or vice-versa? My website goes over a lot of the same subjects as yours and

I think we could greatly benefit from each other. If you’re interested

feel free to send me an email. I look forward to hearing from you!

Fantastic blog by the way!

На сайте https://kupikod.com/ приобретите оригинальный электронный ключ, активируйте различные интересные и новые игры. Сайт предоставляет отличную возможность пополнять счет на самых разных платформах, приобретать музыку, различные приложения. При этом доставка осуществляется максимально оперативно. Все цифровые товары проверены, поэтому полностью исключается брак. На портале вы сможете совершить оплату безопасно, ведь вся информация поступает в запароленном виде. Подобрать то, что нужно можно, воспользовавшись специальным фильтром.

Tonight the Powerball is now worth $580 Million, but with a money worth of $29.six

million.

Here is my blog: FELIX비트볼3분

There is a hotel fitness center accessible to guests staying at Jeju Oriental

Hotel & Casino.

My website :: 라이브카지노사이트 순위

The world is lucky that we have people like yours, who is always there for others.

토토사이트“I’m not ready to say goodbye”…Withdrawal of intention to sell Angels → Impact on Otani’s future?

We are a group of volunteers and starting a brand new scheme in our community.

Your website offered us with useful information to work on. You’ve done an impressive process and our entire neighborhood will likely

be thankful to you.

Roulette is yet a furthe game exactly exactly where it’s probable to adjust things about.

Here is my site :: 해외카지노사이트먹튀

Howdy! pharmacy technician schools online online pharmacies

Currently they’re also coping with the disproportionte

influence of COVID-19 on the Black community.

Also visit my blog … 텐카페알바

Women are great at creating reputations with stronmg foundations for

clientele.

Feel free tto surf to my homepage – 유흥 알바

Which food has the most biotin? My website: kerassentials

Is Avocado good for prostate? My website: prostadine

What gives you energy besides coffee? My website: java burn

As component of the AdventHealth group, you will

get exclusive discounts on choose tickets and season passes.

My blog: 유흥알바

Meb Haber hakkında detaylı bilgi, en son ve güncel öğretmen haberlerine ulaşmak için hemen websitemizi ziyaret edin.

As a instructor myself, I can testify that

a sincere thank you gift can indicate the world.

Many thanks for the ideas in this post.

For detailed information about vps server, the most professional hosting, cloud and domain services, visit our website now.

Greetings! Very helpful advice in this particular article!

It is the little changes that make the largest changes. Thanks for sharing!

https://tutsvarka.ru/raznoe/kak-osushhestvlyaetsya-refinansirovanie-kreditov

generic for cleocin

Later, the Bureau carried out thhe very same sort of survey iin 31 other states.

Feel free to surf too my web page … Charity

Inform us a small about the history of social casino game improvement in South Korea.

my web-site: Milan

alt.com

The card earns rewards from casino play and other spendding at High1 that can bee redeemed

at the resort.

Feel free to surf to my page; 해외카지노

You made my birthday an event to remember.

pro essay writing service motivation and emotion psychology essay phd essay writing service

Hi there! pharmacy technician online pharmacy technician certification online

It iss beneficial if there is Japanese in the hotel description paper for hotel

guests.

Also visit my webpage 라이브카지노사이트도메인

Job categories on Poached involve bar, floor, barista, kitchen, management,hotel, and counter careers.

Feel free to suef to my web site – 쩜오 알바

This is when the Lender holds a greeater card value and also is

proclaimed the champion.

My web blog :: 온라인바카라사이트쿠폰

На сайте https://citaty.life/ ознакомьтесь с цитатами известных, публичных людей, а также теми, что были произнесены в фильмах. Имеются цитаты из книг, к примеру, «Мастер и Маргарита», «Ромео и Джульетта». Опубликованы фразы, которые разошлись на цитаты, из популярных сериалов, мультиков, аниме, из песен востребованных групп. Все они невероятно интересные, любопытные, а потому перечитывать их можно в любое время. Регулярно добавляются новые, чтобы вы ознакомились с ними в данный момент.

Medicines information for patients. Brand names.

buying female viagra price in US

All information about medicament. Get now.

What’s up to all, it’s truly a pleasant for me to pay a visit this web site, it consists of helpful Information.

I constantly spent my half an hour to read this web site’s articles

or reviews all the time along with a cup of coffee.

Кто такой видеограф и фотограф https://videophotos.ru

Female writers and authors have a tendency to earn 98% of what their mawle colleagues make.

Feel free to visit my blog post … 텐프로 알바

Реферат – это самый популярный вид научно-исследовательской, а точнее сказать, учебно-поисковой работы в старших классах школы и на студенческой скамье. Первый опыт всегда пугает. Как правильно оформить реферат? Что такое ГОСТ? Какие источники включают в список литературы? Мы расскажем, как правильно писать реферат, дадим образец и снабдим вас важными подсказками на будущее. Ничего сложного нет – стоит выполнить работу один раз, и вы в этом убедитесь.

Рекомендуем сайт со скидкой промокод студентам на контрольные работы Если вы хотите найти хорошую скидну на написание курсовых, то вам к нам! Любые образовательные услуги по написанию контрольных а так же проконсультируем как написать отчет по практике, мы ждем Вас!

заочник

With the enable of engineering mentors, all-girl

teams from diverse grade levels develop robots and engage tgem in competitors.

Feel free to visit my webpage – 레이디알바

Ремонт квартир под ключ Киев дешево.

Работаем быстро, качественно, держим сроки!

Наш сайт – https://evrorem.kiev.ua/

Lotts of attend moon-viewing events all over the nation for the new year’s 1st complete moon.

My site … 카페 알바

I don’t know whether it’s just me or if perhaps everyone else encountering issues with

your blog. It appears like some of the written text on your posts are running off the screen. Can someone else please comment and

let me know if this is happening to them too?

This could be a problem with my web browser because I’ve

had this happen before. Thanks

Very good post.Really looking forward to read more. Great.

My website: cartoon porn

The South Korean casino affiliate applications we’ll be discussing are

effectively known in Asia, in particular by South Korean players.

Feel free to surf to my web blog – 카지노사이트 쿠폰

During the video game, the gamer can bet on either the player or the financial institution.

Visit my website: 온라인바카라사이트검증

Specifics of job-associated education or other skills improvement activity.

Here is my homepage; 여성 구인구직

Hello I am so glad I found your weblog, I really found you by error, while

I was searching on Digg for something else, Anyways I am

here now and would just like to say cheers for

a marvelous post and a all round interesting blog (I also love the theme/design),

I don’t have time to look over it all at the moment but I have bookmarked it and also included

your RSS feeds, so when I have time I will be back to read more, Please do

keep up the great work.

I all the time used to study paragraph in news papers

but now as I am a user of web so from now I am using net for content, thanks to web.

Hello there! pharmacy technician schools online safe online pharmacy

provigil canada purchase online

I am in fact happy to glance at this webpage posts which contains plenty

of helpful data, thanks for providing these information.

I was recommended this website via my cousin. I am not certain whether or not this put up is

written via him as no one else know such distinctive approximately my

trouble. You are incredible! Thank you!

this is our website come visit hay4d

visit our fastest result on sgp

data hk togelers tercepat pasti terpercaya

visit the best bakery store in town