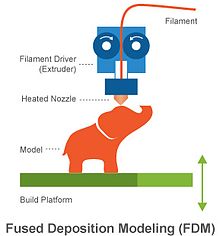

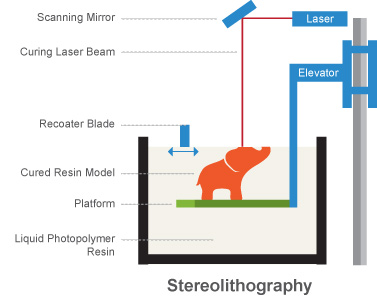

In 3D printing, there are many kinds of printers. Two of the most common are FDM and SLA printers. FDM, or Fused Deposition Molding, printers are the most popular. They use a variety of filaments, most often thermoplastics, that are melted and then deposited layer by layer to create the final print. SLA, or Stereolithography, printers use a liquid resin that is a curable photopolymer. Essentially, the print base is dipped into the resin, and a laser or UV light draws the print layer by layer by curing the resin, which hardens into a solid plastic.

FDM

FDM Printing

From: Printspace3D

Looking specifically at FDM printers, there are a few reasons why they are the more popular option.

Pros

The greatest advantage of FDM printers is pricing. FDM printers are relatively cheap compared to most other 3D printers. They can range in price from $200 to $4,000 for non-industrial printers. In addition to the lower cost of the printer, the running costs of an FDM printer are low. The filament is the only part that needs to be replaced often and is relatively cheap. For example, a spool of standard PLA from 3D-Fuel costs around $30 for a kilogram (2.2 pounds) of filament.

In addition to cost, FDM boasts a wide filament selection. While the most common filament used in FDM printing is PLA (Polylactic Acid) plastic, there are several other kinds, as well as a wide selection of colors.

For example, 3D-Fuel has a variety of different filaments including Wound Up (a coffee filament made from waste by-products of coffee), Buzzed (beer), Entwined (hemp), and Landfillament, a material made from incinerated landfill contents. There are also other types of exotic filaments like carbon fiber, wood-fill, metal-fill, cork-fill, magnetic filament, and filaments that can conduct electricity.

Cons

Although there are clear advantages with FDM, there are disadvantages as well. For one, FDM printing produces prints with a finish that is not as smooth or precise as other types of printing, especially SLA. And, while objects printed with FDM are structurally sound in the X and Y dimensions, they tend to be weak in the Z dimension due to the layering of the printed material. This can cause the print to delaminate or break when under pressure.

SLA

SLA Printing

From: Printspace3D

In addition to FDM, SLA is another 3D printing option that has its own advantages and disadvantages.

Pros

One of the best advantages of an SLA printer is the overall quality of the print. SLA printers are more accurate and print with a smoother finish. In fact, the Form 2 SLA printer can print with a layer height from 25 to 100 microns while common FDM printers can only print with a layer height of 100 to 300 microns. The better resolution that SLA printers provide give their prints a finer surface finish.

In addition, SLA prints do not have the same weakness in the Z dimension that FDM prints have, but SLA prints still do not have the same overall strength of an FDM print.

Cons

However, this quality comes at a cost. While there are SLA printers available for as low as $500, these lower priced printers are not as reliable and user friendly as higher quality desktop printers. A decent desktop SLA printer can cost as much as $4,000 while high-end industrial SLA printers easily price above $100,000.

SLA printers also have high running costs. The resin that is used must be bought from the printer companies as there are no third-party producers for higher end printers. This resin can cost anywhere from $150 to $250 per liter. The tank that holds the resin in the printer will also have to be replaced every three to four liters and can cost upwards of $60.

SLA printers tend to print slower than FDM printers. For example, a FDM printer will print a part in half the time it takes a SLA printer to print the same part. Prints completed on an SLA printer also must go through additional processing after completion, including immersion in isopropyl alcohol to remove any leftover resin. In addition, SLA printers are limited in the sizes of their prints. Considering the higher costs of the printers, the desktop versions tend to be smaller, with less variety in build area sizes compared to FDM.

Things to Consider

There are several other factors to consider for both printers. For example, if SLA prints are exposed to sunlight for extended periods, the print will weaken.

Some factors for FDM printers include nozzle blockages, missing layers, and warping. One particular factor is the size of the extruder nozzle, which influences the resolution and quality of the print.

These, as well as the advantages and disadvantages of each type of printer should be considered before purchasing a 3D printer or deciding which technology to use in making your 3D part.

Which Printer Should You Choose?

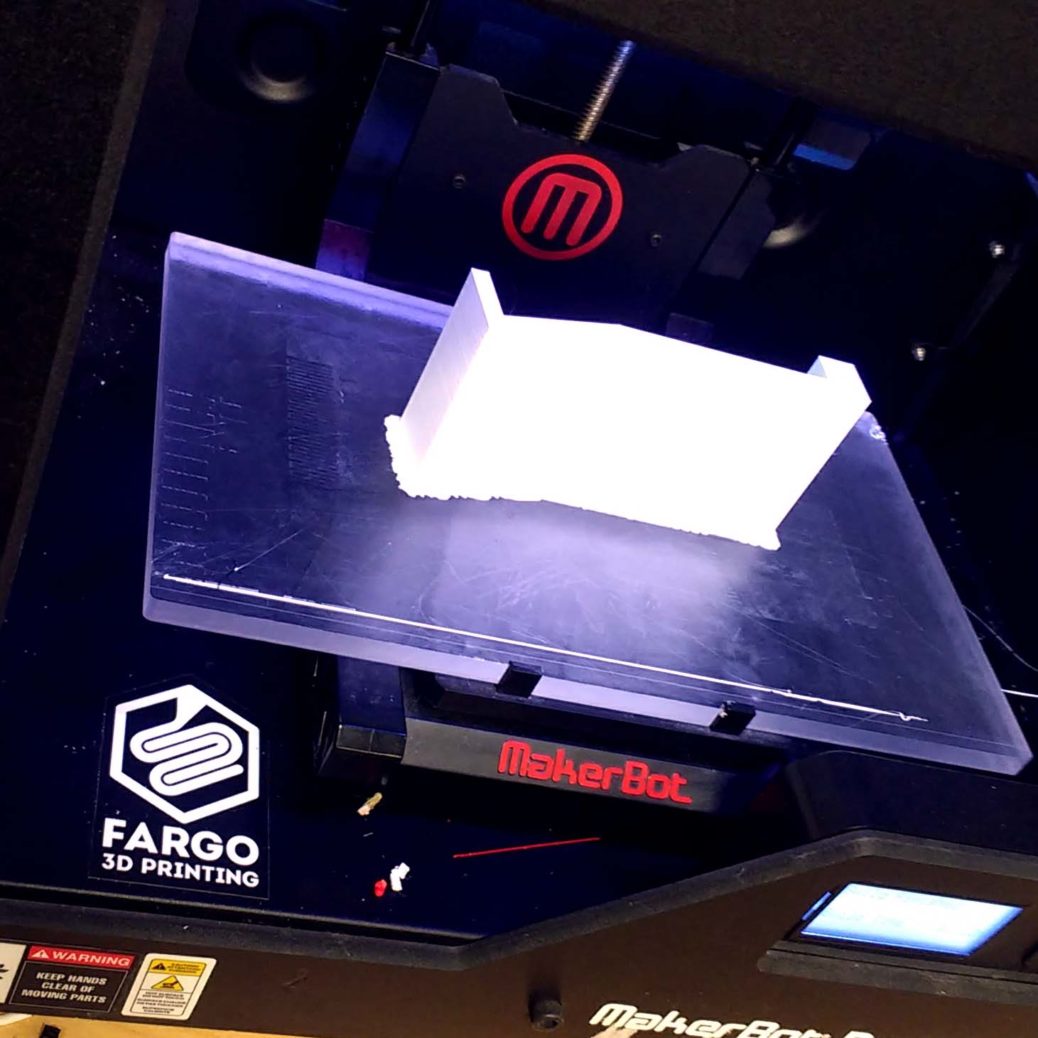

Quality comparison of an FDM print (left) and an SLA print (right).

From: Pinshape Blog

Both FDM and SLA printers are excellent options. The question isn’t which printer is better, but what you need to accomplish with your printer. FDM printers are much better for rapid prototyping, experimenting, and creating low-cost models, especially when precision and finish quality are not important to your project.

On the other hand, SLA printers are better for projects where surface finish and precision are important, such as when creating molds, especially when printer price and the strength of the print are not as important.

[sexy_author_bio]

Please let me know if you’re looking for a writer for your weblog. You have some really good posts and I think I would be a good asset. If you ever want to take some of the load off, I’d love to write some articles for your blog in exchange for a link back to mine. Please send me an e-mail if interested. Many thanks!

Some truly fantastic information, Glad I found this. “Reprove thy friend privately commend him publicly.” by Solon.

https://amoxil.science/# amoxacillian without a percription

Rattling good visual appeal on this site, I’d value it 10 10.

Perfectly indited written content, thank you for entropy. “Life is God’s novel. Let him write it.” by Isaac Bashevis Singer.

Hi, just required you to know I he added your site to my Google bookmarks due to your layout. But seriously, I believe your internet site has 1 in the freshest theme I??ve came across. It extremely helps make reading your blog significantly easier.

epinephrine over the counter antibiotic eye drops over the counter

over the counter anti inflammatories what is the best over-the-counter anti-inflammatory for dogs

I truly appreciate this post. I’ve been looking all over for this! Thank goodness I found it on Bing. You have made my day! Thx again!

best over the counter hair color over the counter uti meds

I believe other website owners should take this website as an example , very clean and superb user friendly layout.

Hi! Someone in my Facebook group shared this site with us so I came to give it a look. I’m definitely loving the information. I’m book-marking and will be tweeting this to my followers! Outstanding blog and amazing style and design.

humana over the counter over the counter allergy medicine

I’ll immediately grab your rss feed as I can’t in finding your e-mail subscription hyperlink or e-newsletter service. Do you have any? Please allow me realize in order that I may subscribe. Thanks.

Hi, I think your site might be having browser compatibility issues. When I look at your website in Safari, it looks fine but when opening in Internet Explorer, it has some overlapping. I just wanted to give you a quick heads up! Other then that, fantastic blog!

Hi, Neat post. There is an issue with your web site in internet explorer, may test thisK IE nonetheless is the marketplace chief and a big portion of folks will pass over your great writing due to this problem.

best over the counter hair color over the counter antibiotics for tooth infection

over the counter adderall uti over the counter medication

You are my intake, I possess few web logs and often run out from to post : (.

over the counter pain meds for dogs metronidazole over the counter

uhc over the counter essentials 2019 nausea medication over the counter

Greetings! I’ve been reading your blog for some time now and finally got the courage to go ahead and give you a shout out from Houston Texas! Just wanted to say keep up the great job!

It?¦s really a cool and helpful piece of info. I am satisfied that you shared this helpful info with us. Please keep us up to date like this. Thank you for sharing.

I like this post, enjoyed this one appreciate it for putting up. “The basis of optimism is sheer terror.” by Oscar Wilde.

I have to convey my passion for your kind-heartedness supporting persons who really need help on this situation. Your personal commitment to passing the message all over had been quite insightful and have without exception encouraged women just like me to arrive at their desired goals. Your own warm and friendly report implies a great deal a person like me and somewhat more to my colleagues. Regards; from everyone of us.

https://drugsoverthecounter.com/# is ivermectin over the counter

Thank you for sharing superb informations. Your web-site is so cool. I am impressed by the details that you have on this site. It reveals how nicely you perceive this subject. Bookmarked this web page, will come back for extra articles. You, my friend, ROCK! I found just the information I already searched everywhere and simply could not come across. What an ideal website.

This really answered my drawback, thanks!

You really make it appear so easy along with your presentation but I in finding this topic to be actually one thing that I believe I would by no means understand. It seems too complicated and very large for me. I am looking ahead to your next post, I’ll try to get the dangle of it!

Thank you for the good writeup. It in fact was a amusement account it. Look advanced to more added agreeable from you! By the way, how can we communicate?

I simply could not leave your site prior to suggesting that I extremely loved the usual info an individual supply on your guests? Is gonna be again often to investigate cross-check new posts

hey there and thanks to your information – I have certainly picked up something new from proper here. I did however expertise several technical points the usage of this site, as I skilled to reload the website many instances previous to I may just get it to load properly. I have been brooding about if your web host is OK? Not that I’m complaining, however sluggish loading circumstances occasions will sometimes affect your placement in google and could injury your quality rating if advertising and ***********|advertising|advertising|advertising and *********** with Adwords. Well I am adding this RSS to my e-mail and could glance out for a lot more of your respective intriguing content. Make sure you update this again soon..

Appreciating the hard work you put into your site and detailed information you present. It’s awesome to come across a blog every once in a while that isn’t the same unwanted rehashed information. Excellent read! I’ve saved your site and I’m adding your RSS feeds to my Google account.

amei este site. Pra saber mais detalhes acesse nosso site e descubra mais. Todas as informações contidas são informações relevantes e exclusivas. Tudo que você precisa saber está ta lá.

Thank you a bunch for sharing this with all folks you actually understand what you are talking about! Bookmarked. Kindly additionally seek advice from my site =). We may have a hyperlink alternate agreement between us!

I really like your writing style, good info , thankyou for posting : D.

I wish to express appreciation to this writer just for rescuing me from this condition. Just after checking through the internet and seeing tips that were not pleasant, I figured my entire life was well over. Existing minus the approaches to the problems you have resolved as a result of your article content is a critical case, as well as ones which may have badly affected my career if I hadn’t discovered your website. That ability and kindness in dealing with all areas was useful. I’m not sure what I would have done if I had not come upon such a solution like this. It’s possible to at this point look forward to my future. Thanks so much for the specialized and sensible help. I will not hesitate to propose your blog to anybody who requires guidance on this matter.

fantastic submit, very informative. I’m wondering why the other specialists of this sector don’t realize this. You should continue your writing. I’m confident, you have a huge readers’ base already!

Really wonderful info can be found on weblog. “Never violate the sacredness of your individual self-respect.” by Theodore Parker.

Thank you for another magnificent article. Where else could anyone get that type of info in such an ideal way of writing? I’ve a presentation next week, and I am on the look for such information.

You are my intake, I own few web logs and often run out from to brand.

As a Newbie, I am constantly searching online for articles that can benefit me. Thank you

Really clear site, thanks for this post.

I enjoy you because of each of your efforts on this site. My mother takes pleasure in doing investigation and it’s really easy to see why. My spouse and i notice all concerning the powerful ways you create useful information via your blog and as well as boost contribution from some other people on the subject and my child has been discovering a lot of things. Enjoy the remaining portion of the year. You are carrying out a splendid job.

Your style is so unique compared to many other people. Thank you for publishing when you have the opportunity,Guess I will just make this bookmarked.2

I am now not positive where you’re getting your information, but good topic. I needs to spend some time studying much more or working out more. Thank you for magnificent info I used to be in search of this information for my mission.

Hey there! This is my first visit to your blog! We are a group of volunteers and starting a new project in a community in the same niche. Your blog provided us beneficial information to work on. You have done a outstanding job!

Thanks for your marvelous posting! I actually enjoyed reading it, you are a great author.I will be sure to bookmark your blog and will often come back in the future. I want to encourage you to ultimately continue your great posts, have a nice evening!

Great post. I am facing a couple of these problems.

Hey There. I found your blog the usage of msn. That is a really smartly written article. I’ll be sure to bookmark it and come back to learn extra of your useful info. Thank you for the post. I will definitely return.

Very nice post. I just stumbled upon your blog and wanted to say that I have really enjoyed browsing your blog posts. In any case I will be subscribing to your feed and I hope you write again soon! okbet philippines

Woh I love your content, saved to favorites! .

Perfect piece of work you have done, this internet site is really cool with great info .

I am not rattling good with English but I get hold this really easy to understand.

As I web site possessor I believe the content matter here is rattling great , appreciate it for your hard work. You should keep it up forever! Best of luck.

Woh I love your content, saved to favorites! .

I went over this site and I conceive you have a lot of wonderful information, saved to bookmarks (:.

I have been absent for a while, but now I remember why I used to love this blog. Thanks , I will try and check back more frequently. How frequently you update your website?

It?¦s really a great and helpful piece of info. I?¦m glad that you shared this helpful information with us. Please keep us informed like this. Thanks for sharing.

Nice post. I learn something more challenging on different blogs everyday. It will always be stimulating to read content from other writers and practice a little something from their store. I’d prefer to use some with the content on my blog whether you don’t mind. Natually I’ll give you a link on your web blog. Thanks for sharing.

I have been reading out a few of your stories and it’s pretty good stuff. I will surely bookmark your website.

Great web site. Plenty of useful information here. I am sending it to several friends ans also sharing in delicious. And naturally, thanks for your effort!

I discovered your blog site on google and check a few of your early posts. Continue to keep up the very good operate. I just additional up your RSS feed to my MSN News Reader. Seeking forward to reading more from you later on!…

Thank you for the sensible critique. Me & my neighbor were just preparing to do some research on this. We got a grab a book from our area library but I think I learned more from this post. I am very glad to see such excellent information being shared freely out there.

I too conceive so , perfectly composed post! .

I was reading through some of your blog posts on this internet site and I conceive this internet site is really instructive! Continue posting.

you have a great blog here! would you like to make some invite posts on my blog?

Hiya! I know this is kinda off topic nevertheless I’d figured I’d ask. Would you be interested in trading links or maybe guest writing a blog post or vice-versa? My blog addresses a lot of the same subjects as yours and I feel we could greatly benefit from each other. If you are interested feel free to shoot me an e-mail. I look forward to hearing from you! Wonderful blog by the way!

Good post and straight to the point. I don’t know if this is truly the best place to ask but do you guys have any ideea where to get some professional writers? Thank you 🙂

Someone essentially assist to make significantly articles I would state. That is the very first time I frequented your website page and to this point? I amazed with the analysis you made to make this actual post incredible. Wonderful activity!

Just wanna input that you have a very nice website , I enjoy the pattern it actually stands out.

Great write-up, I¦m regular visitor of one¦s blog, maintain up the excellent operate, and It’s going to be a regular visitor for a lengthy time.

Real wonderful visual appeal on this web site, I’d value it 10 10.

There is perceptibly a bundle to know about this. I consider you made certain good points in features also.

In the awesome pattern of things you’ll get an A+ for effort. Exactly where you lost everybody was on all the facts. You know, as the maxim goes, the devil is in the details… And it couldn’t be more accurate right here. Having said that, allow me reveal to you precisely what did do the job. Your writing can be extremely engaging and that is most likely why I am making an effort to comment. I do not make it a regular habit of doing that. Second, although I can easily notice the leaps in reasoning you come up with, I am not really confident of just how you seem to unite your points that help to make the conclusion. For the moment I shall yield to your position but hope in the future you link the dots better.

I discovered your blog website on google and examine a couple of of your early posts. Continue to keep up the excellent operate. I simply further up your RSS feed to my MSN News Reader. In search of forward to studying more from you in a while!…

Hiya, I’m really glad I’ve found this info. Today bloggers publish just about gossips and web and this is really irritating. A good web site with interesting content, this is what I need. Thank you for keeping this site, I will be visiting it. Do you do newsletters? Cant find it.

Utterly pent articles, regards for information .

You could definitely see your enthusiasm in the work you write. The sector hopes for more passionate writers such as you who aren’t afraid to say how they believe. Always follow your heart. “There are only two industries that refer to their customers as users.” by Edward Tufte.

I think this is one of the most important info for me. And i am glad reading your article. But want to remark on some general things, The website style is ideal, the articles is really nice : D. Good job, cheers

There is visibly a lot to realize about this. I consider you made certain good points in features also.

I like the valuable info you provide in your articles. I’ll bookmark your weblog and check again here regularly. I’m quite certain I’ll learn many new stuff right here! Good luck for the next!

I’d have to verify with you here. Which is not one thing I usually do! I take pleasure in reading a publish that may make people think. Additionally, thanks for permitting me to comment!

This web site is my inhalation, real excellent style and perfect subject matter.

Hi my loved one! I want to say that this article is awesome, nice written and come with almost all vital infos. I?¦d like to look more posts like this .

As a Newbie, I am constantly searching online for articles that can be of assistance to me. Thank you

Hi there! This is kind of off topic but I need some advice from an established blog. Is it hard to set up your own blog? I’m not very techincal but I can figure things out pretty fast. I’m thinking about making my own but I’m not sure where to begin. Do you have any points or suggestions? With thanks

I like this post, enjoyed this one regards for posting.

Thank you for sharing with us, I think this website genuinely stands out : D.

Heya i’m for the primary time here. I came across this board and I to find It really useful & it helped me out a lot. I hope to give one thing back and aid others such as you helped me.

I was suggested this web site by my cousin. I’m now not certain whether or not this post is written by way of him as nobody else recognize such specific approximately my problem. You’re amazing! Thank you!

Keep up the superb piece of work, I read few articles on this website and I think that your web blog is rattling interesting and holds lots of good information.

There are certainly loads of details like that to take into consideration. That could be a great point to carry up. I offer the ideas above as normal inspiration but clearly there are questions like the one you convey up the place the most important factor will likely be working in sincere good faith. I don?t know if greatest practices have emerged round things like that, however I am certain that your job is clearly identified as a fair game. Each boys and girls feel the impact of only a second’s pleasure, for the rest of their lives.

Thanks for another informative website. Where else could I get that type of information written in such a perfect way? I have a project that I’m just now working on, and I have been on the look out for such info.

Very efficiently written article. It will be helpful to anybody who employess it, including yours truly :). Keep doing what you are doing – for sure i will check out more posts.

I loved as much as you will receive carried out right here. The sketch is tasteful, your authored material stylish. nonetheless, you command get got an edginess over that you wish be delivering the following. unwell unquestionably come more formerly again as exactly the same nearly very often inside case you shield this increase.

Great work! This is the type of information that should be shared around the internet. Shame on Google for not positioning this post higher! Come on over and visit my site . Thanks =)

This is a very good tips especially to those new to blogosphere, brief and accurate information… Thanks for sharing this one. A must read article.

I like your writing style genuinely enjoying this website .

This web site is really a walk-through for all of the info you wanted about this and didn’t know who to ask. Glimpse here, and you’ll definitely discover it.

I believe you have observed some very interesting details, thankyou for the post.

Excellent read, I just passed this onto a friend who was doing a little research on that. And he just bought me lunch since I found it for him smile Thus let me rephrase that: Thank you for lunch! “Do you want my one-word secret of happiness–it’s growth–mental, financial, you name it.” by Harold S. Geneen.

What¦s Happening i am new to this, I stumbled upon this I have discovered It absolutely useful and it has aided me out loads. I hope to contribute & help other customers like its aided me. Great job.

I have recently started a blog, the information you provide on this web site has helped me tremendously. Thank you for all of your time & work.

It¦s really a nice and useful piece of info. I¦m glad that you shared this useful information with us. Please keep us up to date like this. Thank you for sharing.

Just want to say your article is as surprising. The clarity in your submit is just excellent and i can think you are knowledgeable on this subject. Well with your permission let me to grasp your RSS feed to keep updated with coming near near post. Thanks one million and please continue the rewarding work.

I loved as much as you will receive carried out right here. The sketch is attractive, your authored subject matter stylish. nonetheless, you command get bought an impatience over that you wish be delivering the following. unwell unquestionably come further formerly again since exactly the same nearly very often inside case you shield this hike.

Some really prime content on this internet site, saved to bookmarks.

Hi my family member! I wish to say that this post is amazing, nice written and come with approximately all important infos. I’d like to see more posts like this.

Thanks for helping out, good info .

Incredible! This blog looks just like my old one! It’s on a totally different topic but it has pretty much the same layout and design. Great choice of colors!

I have not checked in here for some time since I thought it was getting boring, but the last several posts are great quality so I guess I?¦ll add you back to my everyday bloglist. You deserve it my friend 🙂

Simply a smiling visitor here to share the love (:, btw outstanding style. “Justice is always violent to the party offending, for every man is innocent in his own eyes.” by Daniel Defoe.

Good write-up, I am normal visitor of one’s website, maintain up the nice operate, and It is going to be a regular visitor for a long time.

Its excellent as your other posts : D, thanks for putting up. “Always be nice to people on the way up because you’ll meet the same people on the way down.” by Wilson Mizner.

Whats Going down i’m new to this, I stumbled upon this I have found It absolutely useful and it has helped me out loads. I am hoping to contribute & help other customers like its helped me. Good job.

Nice post. I learn something more challenging on different blogs everyday. It will always be stimulating to read content from other writers and practice a little something from their store. I’d prefer to use some with the content on my blog whether you don’t mind. Natually I’ll give you a link on your web blog. Thanks for sharing.

I like this web site so much, bookmarked.

Absolutely written subject material, regards for entropy.

I was very pleased to find this web-site.I wanted to thanks for your time for this wonderful read!! I definitely enjoying every little bit of it and I have you bookmarked to check out new stuff you blog post.

My spouse and i ended up being very fortunate when Michael managed to finish up his reports while using the ideas he discovered from your very own blog. It is now and again perplexing just to continually be handing out helpful tips that other people could have been selling. Therefore we consider we need the blog owner to thank because of that. The specific illustrations you’ve made, the easy web site menu, the friendships your site assist to instill – it’s all sensational, and it’s making our son and the family imagine that that situation is cool, and that is exceptionally fundamental. Thank you for everything!

Thank you for the auspicious writeup. It in fact was a amusement account it. Look advanced to far added agreeable from you! However, how could we communicate?

Very nice post. I just stumbled upon your weblog and wished to say that I’ve really enjoyed browsing your blog posts. In any case I will be subscribing to your rss feed and I hope you write again soon!

Great – I should certainly pronounce, impressed with your site. I had no trouble navigating through all tabs and related info ended up being truly simple to do to access. I recently found what I hoped for before you know it in the least. Reasonably unusual. Is likely to appreciate it for those who add forums or anything, website theme . a tones way for your customer to communicate. Excellent task..

Great awesome things here. I am very happy to peer your article. Thanks a lot and i’m looking ahead to contact you. Will you please drop me a mail?

It’s a shame you don’t have a donate button! I’d definitely donate to this fantastic blog! I guess for now i’ll settle for book-marking and adding your RSS feed to my Google account. I look forward to new updates and will share this website with my Facebook group. Talk soon!

My spouse and I stumbled over here coming from a different website and thought I should check things out. I like what I see so now i am following you. Look forward to exploring your web page yet again.

Hi there very cool website!! Guy .. Beautiful .. Wonderful .. I will bookmark your site and take the feeds also…I am glad to find so many useful info right here in the post, we want develop more techniques on this regard, thanks for sharing.