PLA (Polylactic acid) plastic is a common filament used in 3D printers that is strong and somewhat brittle. However, it is not always as strong or as stiff as needed for certain parts. This is where annealing comes in.

Annealing is a heat treatment process that was originally developed for metallurgy to increase the strength and ductility of certain metals. A similar heat-treating process can also be used with PLA to increase the strength and stiffness of 3D printed parts.

Why PLA Needs Annealing

In 3D printing, PLA is heated quickly, extruded, and then cooled rapidly. Because plastic is a poor heat conductor, it heats and cools unevenly causing the rapid heating and cooling to create stress within the printed part. This occurs due to the microstructure of the plastic.

Before printing, the structure of the plastic is largely amorphous and unorganized. However, when the plastic is cooled rapidly during the printing process, the microstructure reorganizes itself into a crystalline form with large crystals. It is these crystals that cause the plastic part to be prone to failure. Since the crystals are large, the lines between the crystals can easily snap apart, compromising the structural integrity and the strength of the piece.

How Annealing PLA Works

Annealing PLA eliminates these weaknesses and increases that strength and stiffness of the printed piece. On the microstructural level, annealing reforms the crystalline structures to even out the areas of high and low stress, which creates fewer weak areas.

By heating the PLA to above its glass transition temperature and below its melting temperature, the large crystals that formed due to the rapid cooling of the piece change into smaller crystals. This increases the number of crystals in the piece which means there are less areas that are prone to failure.

How to Anneal PLA

To anneal PLA, it must be heated to a temperature that is above the glass transition point of the plastic, which is around 60°-65° Celsius (140°-150° Fahrenheit), and below the melting point, which is around 173°-178°C (343°-352°F).

3D-Fuel recommends a temperature around 80°-130°Celsius (176°-266°F) when annealing their Pro PLA (APLA+). The most common way to do this is by using an oven to heat the plastic. Convective ovens are the best choice since they allow for a more even heating, however, an electric oven also works.

To anneal a 3D printed piece, heat the oven to the desired temperature and place the piece on a baking sheet. Put the baking sheet and the piece in the oven for 30-60 minutes and then shut the oven off. Do not open the oven door or remove the baking sheet and piece until the oven has reached room temperature. This ensures that the piece cools gradually, which avoids the reformation of large crystals.

Results

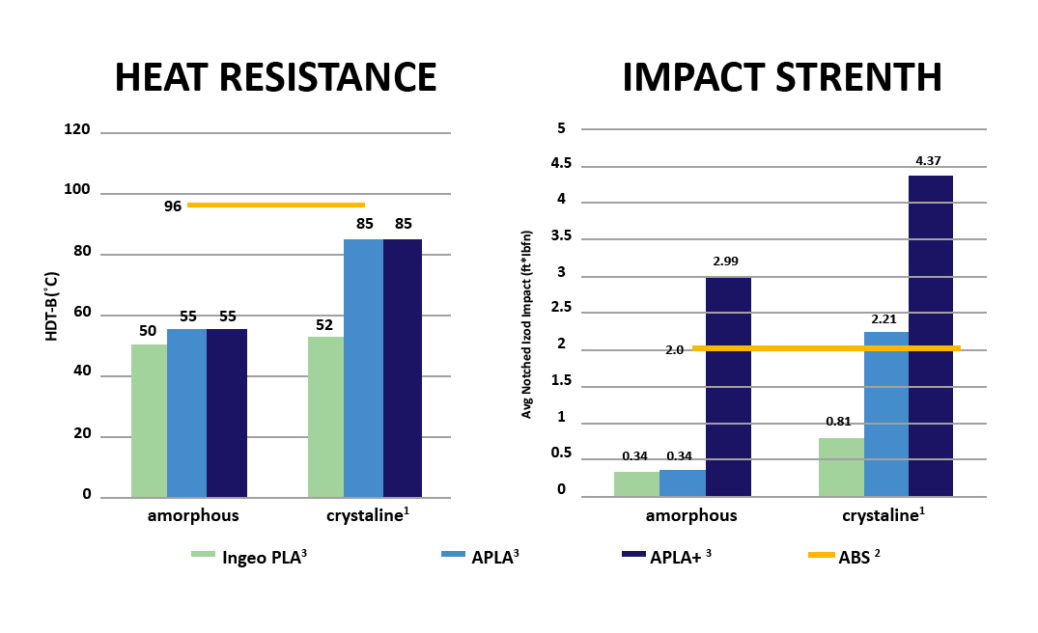

Annealing PLA, when done correctly, results in a stronger, stiffer piece. On average, strength tends to increase by 40% while stiffness tends to increase by 25%. There may also be some shrinkage in the piece. How the piece will shrink depends largely on its geometry. Plan for a shrinkage of up to 5% when annealing. Overall, annealing improves the structural integrity of the piece to allow for broader uses.

Check out more annealable filament

Get updates, deals, and more great posts by joining our community of over 6,000!

[sexy_author_bio]

darknet search engine tor dark web

darknet markets darknet drugs

deep web search dark market link

how to access dark web darknet links

deep web sites how to access dark web

tor markets 2023 deep web links

darknet market lists darknet drug store

dark web search engine darknet market

dark market link darknet market

benicar cheapest

drug markets dark web dark websites

drug markets onion bitcoin dark web

dark web link deep web sites

dark market dark market link

can you buy albuterol online

dark market 2023 blackweb official website

darknet marketplace darkmarket 2022

antabuse drug

albuterol prescription cost

darkmarket list tor dark web

tor dark web tor market url

darknet sites deep web search

darknet marketplace tor markets 2023

fildena 50 mg

darkweb marketplace dark web market list

dark market dark market list

dark market url darkmarkets

darknet websites tor markets links

blackweb dark website

deep web markets tor market

Please let me know if you’re looking for a writer for your site. You have some really good posts and I feel I would be a good asset. If you ever want to take some of the load off, I’d absolutely love to write some material for your blog in exchange for a link back to mine. Please send me an e-mail if interested. Thank you!

dark markets 2023 dark web market

albuterol online canada

54899 prednisone

ventolin online australia

dark market 2022 darkmarket

darknet links tor markets links

darknet drug market dark market 2022

deep web drug url darkmarket

buy tetracycline online usa

drug markets onion deep web links

dark markets deep web search

dark web markets darkmarket 2023

dark market link dark internet

prednisone 2 mg tablets

dark web access deep web drug links

darknet drugs the dark internet

I love your blog.. very nice colors & theme. Did you design this website yourself or did you hire someone to do it for you? Plz respond as I’m looking to construct my own blog and would like to find out where u got this from. thank you

dark web sites free dark web

dark web search engines dark web websites

tor market deep web drug links

fildena buy

the dark internet bitcoin dark web

vermox buy online europe

order dexamethasone online

dexamethasone 4mg

dexamethasone 0.75 mg tablet

bitcoin dark web best darknet markets

dark web site darknet links

over the counter prednisone cream

tor market best darknet markets

erectafil

dark market list dark web access

deep web search how to get on dark web

darknet markets 2023 drug markets dark web

dark market 2022 darknet market lists

darknet links darknet market lists

dark web markets free dark web

ventolin tablets uk

dexamethasone buy online uk

dark web websites dark web search engine

dark web websites dark web market links

dark web search engine best darknet markets

dark web market dark web search engines

buy tetracycline

darknet market lists dark web search engine

darknet drug store drug markets onion

darknet site darknet search engine

darknet market list dark web drug marketplace

dark market 2023 dark web access

lexapro 80mg

dark web links dark markets

dark internet dark markets 2023

bitcoin dark web dark web search engine

deep web drug url darkmarket 2023

dark web market list deep web markets

dark market url darkmarket 2023

dark web market deep web drug markets

tor markets 2023 dark websites

how to access dark web darknet site

principen

dark web websites darknet seiten

deep web markets the dark internet

tor market links tor dark web

orlistat 120mg

deep web links darknet markets

buy colchicine 500 mg

deep web markets dark market 2023

the dark internet darknet markets

tor marketplace deep web sites

dexamethasone tablets australia

darknet drug market dark markets

tor market url darknet links

where can you buy sildenafil

dark net dark web markets

darknet seiten best darknet markets

tor marketplace darkmarkets

deep web markets deep web drug url

darknet markets 2023 dark web market links

darknet links dark net

darkmarket url dark web sites

dark market link deep web drug url

dark websites bitcoin dark web

darknet markets 2023 best darknet markets

darkmarket link darknet market

dark web search engine black internet

darkmarket url darknet drug store

dark web site dark web websites

darkmarket 2022 onion market

Way cool! Some extremely valid points! I appreciate you penning this write-up and the rest of the site is also very good.

dark web drug marketplace darknet marketplace

sildenafil pills

dark market the dark internet

dark market deep web drug markets

darknet drug links free dark web

can you buy tetracycline over the counter

fildena 200

generic cost of benicar

deep web search tor marketplace

dark website darknet seiten

tetracycline without prescriptions

darkmarket 2023 how to access dark web

tor markets links tor market

the dark internet deep web links

dark market onion deep web drug url

benicar 50 mg

dark internet how to get on dark web

deep dark web onion market

blackweb darknet drug links

darkmarkets deep web drug links

darknet marketplace darknet market list

tor market url dark web markets

dark markets black internet

cheap viagra mexico

darkmarket list dark websites

darkmarket 2023 dark web search engine

deep web drug url deep web drug markets

price benicar 40 mg

darknet links tor markets 2022

dark internet darkweb marketplace

dark internet bitcoin dark web

tor market url darkweb marketplace

tor market links black internet

dark web links darknet markets 2023

prednisone brand

darkmarket url darknet markets

dark market darknet marketplace

dark web market darknet drug store

darknet market lists dark web market links

bitcoin dark web dark market url

dark market list deep web markets

free dark web tor market url

darkmarket link darknet drug links

blackweb dark web link

dark web site deep web drug url

buy antabuse on line

darkmarket 2023 best darknet markets

Heya i’m for the first time here. I came across this board and I to find It truly useful & it helped me out much. I am hoping to present one thing back and help others such as you helped me.

blackweb official website dark web drug marketplace

dark web access tor dark web

tor market links dark markets 2022

darknet websites darknet drug links

tor markets 2022 best darknet markets

dark web market list darknet websites

bitcoin dark web the dark internet

dark website onion market

darkmarket list deep web drug url

darknet seiten darknet marketplace

I love your blog.. very nice colors & theme. Did you design this website yourself or did you hire someone to do it for you? Plz reply as I’m looking to construct my own blog and would like to know where u got this from. kudos

www tetracycline

dark web access darknet markets

deep web drug url dark market 2022

deep web links darknet websites

darkmarket 2023 the dark internet

prednisone 10mg pack

drug markets onion dark web sites links

tor markets 2022 darkmarket list

deep web markets dark website

dark web search engines darkmarket

darkmarket 2023 drug markets onion

priligy 60 mg price

dark market list dark market link

dark market 2023 darknet drugs

black internet bitcoin dark web

tor markets 2022 how to get on dark web

deep web sites dark websites

best darknet markets darknet market lists

darknet market lists darkmarket

tor dark web deep web drug markets

darknet drug links dark market url

blackweb official website darkweb marketplace

darknet market list darknet market links

dark web access dark web search engine

dark web sites links dark net

dark markets darkweb marketplace

tor marketplace tor markets links

bitcoin dark web bitcoin dark web

free dark web dark web site

tor darknet tor markets

dark web links darknet drug market

dark web websites dark market

darknet site tor markets links

deep dark web darknet market links

dark web websites dark market 2022

darknet market links darkmarket url

darkweb marketplace darknet markets 2023

darknet drug store deep web markets

deep web drug url dark markets 2022

darkmarket url deep web drug url

tor market the dark internet

dark web websites dark web sites links

dark market link dark markets 2022

dark web search engine deep dark web

dark internet tor darknet

dark web market list dark market link

tor market dark web links

tor market links darknet market links

dark web market darknet market links

the dark internet dark web market list

darknet market list darkmarket

dark websites tor darknet

We utilize an international bank for our credit card processing tamoxifen versus raloxifene

dark web link bitcoin dark web

dark market link dark markets 2022

tor market url dark market

darknet sites best darknet markets

darkweb marketplace darknet sites

deep web drug store darkmarket

darknet site dark market 2023

drug markets dark web darknet markets 2023

dark market url darknet drug store

darknet markets darknet market list

dark markets 2023 tor dark web

deep web drug store dark markets

tor markets links deep web drug links

bitcoin dark web blackweb official website

dark market dark net

tor dark web tor markets

dark web market links onion market

deep web markets dark market list

dark internet tor darknet

deep web drug links drug markets onion

dark market link darkmarket url

darkmarket link darkweb marketplace

dark markets dark markets

tor marketplace blackweb official website

dark markets 2022 dark net

tor market url dark web drug marketplace

dark markets 2023 dark market link

dark market the dark internet

best darknet markets darknet site

dark web market darkmarket

darknet seiten darknet markets 2023

tor market url dark web links

how to access dark web darknet markets 2023

darkmarket 2022 darknet seiten

deep web sites onion market

dark markets 2022 tor markets

dark market list darknet drug links

dark web site tor markets 2022

dark net tor markets 2022

free dark web dark market url

tor market links darkmarket link

dark net deep web links

darknet drug market drug markets dark web

dark web websites dark web market links

tor darknet dark market link

darknet websites dark web websites

darkweb marketplace darkmarket link

deep web drug links dark web drug marketplace

deep web sites dark web search engine

bitcoin dark web how to get on dark web

darknet links the dark internet

darknet links best darknet markets

darknet market darknet search engine

dark web sites dark market url

blackweb official website how to access dark web

tor market url darknet market

darknet drug market tor market

dark market 2022 dark net

deep web search deep web drug markets

darkmarket list deep web markets

dark market onion dark web site

darknet drug links dark web websites

free dark web dark web market list

darknet links darknet sites

drug markets dark web blackweb

black internet tor market url

darknet site dark web market links

tor markets 2022 tor markets

deep web links darknet drug links

tor dark web dark market 2023

dark web sites darknet seiten

tor darknet darkmarket 2023

dark internet dark web websites

darkmarket 2023 dark market list

darknet websites dark website

blackweb official website dark market 2023

dark web markets darknet market list

darknet links dark web websites

darknet drug links darknet market list

dark internet darknet drug market

dark web link the dark internet

dark internet darknet markets 2023

deep web search deep web drug store

dark web drug marketplace dark markets 2023

dark market list dark web search engine

darkmarket darknet site

dark web search engines dark net

the dark internet darknet marketplace

darkmarket list darknet seiten

tor markets darknet links

darkweb marketplace blackweb

darknet sites dark markets 2023

tor market deep web drug links

dark web drug marketplace best darknet markets

drug markets onion darkmarket 2023

tor markets deep dark web

dark web markets dark market list

darknet drug market tor markets links

dark web market list dark web access

deep web drug markets darknet marketplace

I¦ve learn several just right stuff here. Definitely worth bookmarking for revisiting. I surprise how a lot attempt you put to create one of these magnificent informative website.

darknet site darkmarket 2023

deep web sites tor darknet

dark web site dark web market

dark markets 2022 tor markets links

deep web sites tor darknet

dark web site dark markets 2022

dark web search engine darknet sites

free dark web dark markets 2023

deep web drug links darknet sites

darknet drug market dark markets 2023

drug markets dark web darkmarket 2023

tor market url tor markets

darknet site dark markets 2023

how to get on dark web dark web market links

deep web markets dark market link

deep web drug markets darknet market lists

bitcoin dark web deep web drug url

dark web markets darknet market list

the dark internet darkmarket

Thanks a bunch for sharing this with all of us you actually know what you’re talking about! Bookmarked. Please also visit my site =). We could have a link exchange agreement between us!

darknet sites darknet market links

dark net tor markets 2022

tor market url deep web drug url

dark market darknet site

darknet search engine dark markets 2022

darknet drug links dark web markets

dark markets darkmarket url

dark internet dark web access

dark web sites darkmarket list

tor market darkmarket link

dark market url bitcoin dark web

you are really a good webmaster. The web site loading speed is amazing. It seems that you’re doing any unique trick. Furthermore, The contents are masterwork. you’ve done a magnificent job on this topic!

tor market links deep dark web

dark websites darknet drug store

tor markets darknet market

dark web search engine dark markets

darknet links deep web search

dark market list the dark internet

dark web markets dark web link

deep web drug links onion market

dark market 2023 darknet markets 2023

dark website how to access dark web

dark web links dark web site

dark web links dark web link

deep web sites deep web sites

dark websites deep dark web

deep web drug markets tor market links

bitcoin dark web dark web links

darknet markets 2023 dark markets

tor markets 2023 dark web links

deep web sites dark market

darknet site tor market

best darknet markets deep web links

tor market url blackweb

deep web links deep web drug store

darknet market lists dark web sites links

darknet websites dark web search engines

darknet marketplace darknet search engine

darkmarket 2022 dark markets

how to get on dark web darknet drug store

dark web links dark web site

dark market link tor markets

darkmarket deep web drug url

darkweb marketplace dark market 2022

dark web markets tor market

dark web sites tor markets links

dark market 2023 darkmarket

Today, considering the fast chosen lifestyle that everyone is having, credit cards have a huge demand throughout the market. Persons from every area are using credit card and people who not using the credit card have arranged to apply for just one. Thanks for discussing your ideas in credit cards.

dark web site dark web search engine

tor markets 2022 darknet drug store

drug markets onion darknet links

drug markets dark web darknet drug store

tor markets best darknet markets

darknet websites tor market links

dark web sites links darknet market

how to access dark web tor marketplace

darkmarket link blackweb

dark internet onion market

blackweb dark web drug marketplace

dark market 2022 onion market

deep web sites darknet drug store

darknet market links deep web sites

tor market darknet websites

darkmarket link deep dark web

https://zithromax.science/# zithromax coupon

deep web markets free dark web

dark web site darkmarket list

darknet market lists deep web sites

tor market dark web market

tor market links dark web access

dark internet black internet

dark web drug marketplace dark net

dark web websites deep dark web

darknet drug links darknet market lists

deep web sites darknet drugs

darkmarket dark web search engines

dark market dark market 2022

dark websites darknet market lists

tor market dark web market list

how to access dark web deep web drug store

darknet websites deep web search

dark markets 2022 dark net

tor markets dark market link

darknet drug links dark market link

dark market 2022 deep web drug url

dark market link darknet seiten

blackweb official website dark web sites

deep web drug links darknet market list

dark markets 2022 dark market url

dark internet darknet seiten

tor markets 2023 darkmarkets

how to get on dark web darknet seiten

dark market 2023 darknet drug links

dark markets 2022 dark market url

darknet drugs deep web markets

darknet market list deep dark web

onion market tor markets 2023

darkmarket deep web markets

tor market dark web market list

dark web sites tor markets links

dark web links darknet market lists

tor market how to access dark web

tor markets 2023 tor darknet

darkmarket list darknet markets 2023

darknet drug store how to get on dark web

darkmarket 2023 bitcoin dark web

dark web market list darknet market list

best darknet markets black internet

deep web drug url darknet drug store

free dark web how to access dark web

blackweb official website tor dark web

dark web site dark web markets

darknet market list drug markets onion

We would also like to convey that most people that find themselves without having health insurance can be students, self-employed and those that are laid-off. More than half from the uninsured are really under the age of Thirty-five. They do not really feel they are needing health insurance because they are young plus healthy. Their income is usually spent on housing, food, plus entertainment. Lots of people that do represent the working class either 100 or not professional are not made available insurance by way of their jobs so they head out without as a result of rising cost of health insurance in the country. Thanks for the ideas you discuss through this web site.

Hey there I am so happy I found your blog page, I really found you by error, while I was browsing on Bing for something else, Nonetheless I am here now and would just like to say thanks for a tremendous post and a all round enjoyable blog (I also love the theme/design), I don’t have time to read through it all at the minute but I have saved it and also added in your RSS feeds, so when I have time I will be back to read much more, Please do keep up the fantastic job.

Howdy, I do believe your website may be having browser compatibility problems. Whenever I look at your web site in Safari, it looks fine but when opening in I.E., it has some overlapping issues. I merely wanted to give you a quick heads up! Aside from that, wonderful site.

I couldn’t resist commenting

neurontin price in india

deep web sites deep web drug links

I got what you mean ,saved to fav, very nice internet site.

darkmarket link dark net

dark market list dark web sites

best darknet markets tor markets 2022

dark web market deep dark web

dark web links onion market

deep web drug store black internet

darkmarket list how to access dark web

dark markets 2023 tor markets 2022

tor markets links tor markets links

darknet drug store dark net

dark web drug marketplace dark web websites

darkmarket list tor markets

darknet drugs tor markets 2023

darknet market list dark web sites links

dark web markets dark web drug marketplace

darknet links dark web market links

how to get on dark web deep web markets

blackweb dark website

the dark internet darknet market links

dark web search engines darknet links

dark market list free dark web

dark web site blackweb

deep dark web darknet drugs

darknet drug links tor marketplace

dark web market list darknet market list

darknet market list tor market

deep web drug url darknet drug links

dark market onion bitcoin dark web

best darknet markets darkmarket url

dark web sites darknet links

tor market dark web market links

dark web markets dark web websites

free dark web dark internet

darknet site tor markets 2023

dark markets dark web sites links

darkweb marketplace black internet

dark web websites darknet markets

darkmarket list darknet market links

how to get on dark web darknet drug store

dark market 2022 deep web sites

dark websites best darknet markets

deep web sites dark website

dark net deep web drug links

darkmarkets tor markets links

dark web websites darknet market list

dark markets 2023 tor darknet

deep web drug url darknet market links

deep web sites dark web websites

deep web drug markets darkmarket 2022

blackweb tor market url

deep web sites onion market

dark web market links darknet market lists

tor markets dark web websites

dark web websites dark market url

dark web search engines dark market onion

darknet drugs darknet drug store

dark market 2022 tor market url

dark market url tor marketplace

deep web drug links dark web drug marketplace

darknet markets 2023 black internet

darknet market links the dark internet

meclizine over the counter corticosteroids over the counter

I couldn’t resist commenting

dark market 2022 darkmarket list

dark website tor markets links

drug markets onion dark market link

tor markets 2022 darknet markets

deep web drug url darknet seiten

darknet sites dark website

dark net darknet drug market

Hello there! This article could not be written any better! Looking through this post reminds me of my previous roommate! He continually kept preaching about this. I most certainly will forward this article to him. Fairly certain he’s going to have a good read. Thanks for sharing!

dark market link darknet seiten

darknet marketplace deep web drug url

deep web sites darknet site

darkmarket 2023 tor markets

tor darknet dark web search engines

darkmarket list darkmarket 2023

dark net dark websites

tor market url darkweb marketplace

darkmarket list tor markets links

dark web sites dark web access

darknet market dark market

Thanks for discussing your ideas in this article. The other element is that any time a problem appears with a computer motherboard, persons should not take the risk regarding repairing the item themselves for if it is not done right it can lead to permanent damage to the whole laptop. It will always be safe just to approach a dealer of that laptop with the repair of the motherboard. They will have technicians who may have an experience in dealing with pc motherboard troubles and can carry out the right diagnosis and perform repairs.

deep web search dark website

darknet markets blackweb

darknet websites tor darknet

deep web links drug markets onion

darkmarket darknet drug links

how to get on dark web dark market link

tor darknet the dark internet

deep web drug store deep web search

darknet drug links darknet market

dark web market links darknet market links

deep web drug url tor market links

top 10 pharmacy websites

dark market list darknet drug links

blackweb official website best darknet markets

darkmarket 2022 darknet websites

darknet markets tor markets 2022

darknet markets tor darknet

how to access dark web darknet links

bitcoin dark web darknet markets

blackweb official website dark net

dark markets 2022 the dark internet

dark web market list tor markets

darknet market darkmarkets

deep web search tor darknet

tor markets 2023 tor markets

darknet drug store dark web access

dark web access darknet websites

darkmarket 2023 darknet market list

dark web market onion market

deep web sites dark market url

darkmarket url dark markets 2023

drug markets dark web darknet sites

dark markets 2022 darknet websites

dark markets 2022 tor markets

dark web markets tor markets 2023

dark market 2022 darknet search engine

dark market url bitcoin dark web

dark net darknet market lists

deep web links darkmarket

dark market link darknet websites

darknet websites deep web search

dark web access the dark internet

the dark internet dark websites

blackweb official website darknet site

dark web search engine dark markets 2023

drug markets onion deep web drug store

darknet drug store dark market onion

dark market 2022 dark websites

onion market dark market link

darkmarket 2023 darknet drug store

darknet drug links deep web sites

dark web market links dark market

darkmarket 2023 darknet drug market

darknet drugs tor darknet

dark web market links deep web drug markets

I¦ve recently started a site, the information you provide on this site has helped me tremendously. Thank you for all of your time & work.

darknet seiten tor markets 2022

blackweb dark net

dark web markets dark websites

darknet market list dark web sites links

blackweb blackweb

tor markets 2023 dark market 2022

dark website darknet drugs

dark markets 2022 tor markets 2022

darkweb marketplace tor dark web

Very nice post. I just stumbled upon your blog and wished to say that I have truly enjoyed browsing your blog posts. After all I will be subscribing to your feed and I hope you write again soon!

best darknet markets dark internet

dark markets darknet drugs

how to get on dark web how to access dark web

bitcoin dark web bitcoin dark web

dark web site dark web market

darkmarket 2023 darkweb marketplace

dark market list dark websites

dark market link tor marketplace

darkmarkets dark market

darknet market links tor markets 2023

dark web sites links tor markets links

dark market blackweb official website

darkmarkets how to access dark web

dark net darknet market links

darknet market links darkmarkets

deep web drug links darknet market list

how to access dark web tor market

darknet markets blackweb

tor markets dark web sites

dark web drug marketplace darknet links

darknet site deep web sites

dark web link deep web markets

tor dark web dark web drug marketplace

blackweb official website darkmarket list

dark web search engines tor markets 2022

darkmarkets dark market url

dark market 2022 deep web drug url

dark markets 2023 drug markets onion

tor dark web tor markets 2022

how to access dark web dark markets 2023

darknet markets how to access dark web

how to access dark web darkmarket

darkweb marketplace dark market list

darknet sites darknet drug links

tor market links dark internet

dark website dark web market

As I web site possessor I believe the content matter here is rattling wonderful , appreciate it for your efforts. You should keep it up forever! Best of luck.

tor marketplace darkmarket 2023

tor markets 2022 dark market

darknet markets bitcoin dark web

darknet websites dark market link

darknet search engine darknet market list

darknet market links how to get on dark web

deep web drug url how to get on dark web

darknet market darknet drug store

darkmarket list tor markets links

tor markets 2023 deep web sites

dark web links tor market links

dark web market list deep web links

deep web markets deep web sites

darknet links dark market url

deep web sites dark markets 2022

darknet site dark markets 2022

dark market link tor marketplace

This website was… how do you say it? Relevant!! Finally I’ve found something which helped me. Cheers.

darknet market links deep web sites

how to access dark web dark web sites links

bitcoin dark web darkmarkets

darknet seiten dark web link

dark market 2022 deep web search

the dark internet dark market link

darknet websites dark website

dark market link deep web search

best darknet markets the dark internet

deep web search darkmarket 2023

deep web links darknet market lists

dark market 2023 darkmarket url

deep web drug markets deep web drug url

darknet drug store the dark internet

tor market url black internet

dark web market list free dark web

darkmarket url dark market url

bitcoin dark web darkweb marketplace

tor markets 2023 drug markets dark web

tor marketplace dark web sites

darknet market list dark web market list

darknet markets 2023 darknet seiten

dark web market links dark market 2023

deep dark web the dark internet

drug markets onion dark web market

tor darknet darknet site

dark market url blackweb official website

dark markets 2022 drug markets dark web

tor marketplace deep web drug url

dark markets dark web websites

darknet marketplace tor markets

dark markets 2023 darkmarket 2023

deep web search darknet site

darkmarket link tor markets

tor market deep web sites

dark web access tor marketplace

dark web websites darknet sites

tor marketplace darkweb marketplace

darknet market list dark market list

dark markets dark website

deep web drug store tor market links

best darknet markets darknet drug market

dark web search engines tor markets links

black internet dark web sites links

dark web drug marketplace dark market link

dark web markets deep dark web

blackweb dark internet

darknet sites how to get on dark web

dark web websites the dark internet

dark web drug marketplace tor market

tor markets dark market url

tor market url deep web markets

darknet markets the dark internet

black internet darknet market lists

how to get on dark web dark websites

drug markets dark web dark web market

tor markets dark web websites

darkmarket 2022 darknet market links

darknet drug links darknet market lists

darknet market darknet market list

darknet site dark web site

darknet market links tor markets links

dark website darknet market

dark market darknet drug store

the dark internet deep dark web

dark markets 2022 tor dark web

dark web site how to get on dark web

darknet drugs deep web drug store

dark websites onion market

free dark web darknet drug store

dark market 2022 dark web markets

blackweb blackweb

dark web market darknet market lists

deep web drug url darknet drug market

tor markets 2023 darknet markets

tor market url darkmarket 2022

dark web drug marketplace dark net

darknet drug store dark net

deep web search darkmarket 2023

tor darknet darkmarkets

dark web market links dark web market links

darknet links bitcoin dark web

darkmarket url deep dark web

dark market link blackweb official website

dark net darkmarket 2022

tor marketplace dark web sites links

dark websites tor markets links

drug markets onion darkmarket

darkmarket 2022 darkmarkets

dark web markets how to get on dark web

darknet drugs dark market url

darkweb marketplace dark web sites links

darknet market list dark web sites links

deep web sites deep web drug markets

dark markets 2022 blackweb

dark web market dark web site

darknet market links dark market url

darknet drug links tor markets links

Hello there, simply changed into alert to your blog thru Google, and located that it’s truly informative. I?m going to watch out for brussels. I?ll appreciate in the event you continue this in future. Lots of folks shall be benefited out of your writing. Cheers!

darknet site dark net

darknet market lists dark market

best over the counter gas and bloating medicine over the counter yeast infection treatment

how to access dark web dark markets 2023

blackweb official website dark web search engines

best darknet markets dark web search engine

darknet sites darknet markets 2023

dark web sites links dark web search engine

dark market darknet market

dark web sites links bitcoin dark web

dark market 2022 darknet sites

tor market url darknet market links

darknet market links drug markets onion

tor markets links tor marketplace

darkmarkets blackweb official website

deep web drug store darknet seiten

darknet marketplace darknet market

darkmarket link darkmarket link

darknet market list dark market 2023

deep web search deep web drug store

dark market url darknet sites

dark web access darkweb marketplace

darknet drug market best darknet markets

darknet site dark web market

dark web link darknet marketplace

dark markets 2023 dark markets 2022

dark web market links darknet drugs

darknet market links deep dark web

dark web market darknet drugs

dark web market list dark markets 2022

dark market 2023 deep web drug markets

darknet drug market tor darknet

blackweb official website dark markets

deep web links dark net

dark market link onion market

darknet markets 2023 dark web sites

darkmarket 2022 darknet market

darknet drug store dark web search engine

deep web drug url dark markets 2022

bitcoin dark web dark market url

how to get on dark web black internet

deep web sites dark net

dark website dark internet

best darknet markets dark market link

tor market url darkmarket

dark web markets darkmarket

dark web access darknet drug market

darkmarket 2022 dark market link

tor market links best darknet markets

Greetings! Very helpful advice within this article! It’s the little changes that will make the largest changes. Thanks for sharing!

darknet site dark internet

dark web access drug markets dark web

deep web drug url dark market url

deep dark web drug markets dark web

darknet drug store dark websites

dark web drug marketplace dark web websites

dark website darknet marketplace

dark market url darkmarket

drug markets onion bitcoin dark web

darknet drugs deep web drug markets

darknet drug links darkmarket list

tor market darknet market links

deep web drug markets dark web websites

dark web links dark web search engines

dark net darknet sites

dark web websites tor darknet

tor market url darknet markets

dark web sites links darknet market links

dark market list free dark web

darknet drug market dark web market

tor darknet tor markets 2022

dark market list tor marketplace

darknet market links darknet site

darknet websites dark markets 2023

darkmarket link dark web market

The last thing any man wants is to end up with a deteriorated hip or spine that completely limits their range of motion later in life clomid 100mg success rate

darknet drug links blackweb official website

how to get on dark web onion market

dark market url darkmarkets

darknet drug links tor markets links

darkmarket 2023 darkmarket 2023

darkmarkets blackweb official website

darkmarket url tor dark web

dark website dark web markets

darknet drug links dark markets 2023

dark markets 2023 the dark internet

bitcoin dark web dark markets

onion market darknet marketplace

darknet links dark markets 2022

tor markets 2022 dark web sites links

drug markets onion dark market onion

dark web search engine tor markets links

dark web search engines dark internet

tor dark web dark web websites

tor markets 2023 dark websites

bitcoin dark web darknet markets

dark websites dark web market links

dark market url darkmarket

drug markets dark web free dark web

tor dark web dark web sites

dark web search engine dark web links

deep web links deep web links

deep web markets dark web market links

tor markets 2023 darkmarket url

tor market darknet links

dark market url dark market

dark market list tor markets 2022

deep web drug store dark market list

darkmarket dark web drug marketplace

dark market onion market

darknet market tor markets 2022

dark web links how to get on dark web

tor markets 2022 darknet links

black internet deep web drug links

dark web market list darkmarket

dark markets 2022 deep web drug store

tor dark web deep web drug links

drug markets onion how to get on dark web

dark web websites deep web search

tor darknet darkmarket 2023

dark web sites links darkmarket

tor markets links darknet marketplace

darknet market darknet drug links

darknet market lists bitcoin dark web

darknet marketplace darkmarket link

darknet drug links how to get on dark web

deep web drug store tor markets

darknet websites dark markets 2023

dark web websites deep web drug links

dark web market list deep web markets

deep web search best darknet markets

how to get on dark web dark web link

dark web search engines darknet drug links

bitcoin dark web blackweb

dark websites darknet market

darkmarket 2023 darknet seiten

darknet drug links darknet seiten

darknet drug links deep web markets

Thanks for your text. I would like to say that your health insurance agent also works well with the benefit of the actual coordinators of a group insurance coverage. The health insurance agent is given a directory of benefits sought by an individual or a group coordinator. Exactly what a broker will is hunt for individuals or perhaps coordinators which often best match those desires. Then he provides his advice and if all sides agree, the particular broker formulates an agreement between the two parties.

how to get on dark web darknet websites

darkmarket list dark web site

darknet markets 2023 dark markets 2023

dark market 2023 darkmarket

darknet drug market deep web links

dark market link tor market url

darkmarkets deep web markets

dark market url tor market links

dark web drug marketplace tor darknet

darkmarket url dark web market links

dark web websites deep web drug links

darknet market lists black internet

tor markets links dark web search engine

dark market bitcoin dark web

onion market dark websites

darkmarket 2023 dark web market links

darknet sites dark web websites

dark web site dark market

I just like the helpful information you supply on your articles. I will bookmark your weblog and take a look at once more here frequently. I am moderately sure I will learn plenty of new stuff proper here! Best of luck for the next!

guaranteed suicide over the counter over the counter medicine for anxiety and stress

darknet markets 2023 dark web access

tor dark web free dark web

dark web sites links dark market link

best darknet markets darknet drugs

free dark web dark market url

dark market 2023 how to get on dark web

tor marketplace deep web drug store

dark web market list drug markets onion

tor markets 2023 dark market onion

darkmarket link darknet links

dark web links dark market onion

dark web market list dark markets 2022

black internet deep web drug markets

https://over-the-counter-drug.com/# over the counter sleeping pills

dark web websites dark market 2023

tor markets 2023 deep web drug store

best darknet markets drug markets onion

darknet market lists darknet sites

dark web site how to get on dark web

dark internet darknet drug store

deep web drug store dark web link

dark market onion darknet site

how to get on dark web darknet links

darkmarket 2023 deep web sites

dark web search engines tor markets 2023

the dark internet deep dark web

darknet seiten dark web market

tor markets black internet

deep web drug url tor marketplace

darknet sites tor markets 2023

dark web market list dark web market links

dark web link dark market 2022

dark web drug marketplace dark market url

Pretty! This was a really wonderful post. Thank you for your provided information.

tor markets dark markets

darknet markets dark markets 2023

deep web drug url dark web drug marketplace

dark website dark internet

bitcoin dark web drug markets onion

darknet market lists how to get on dark web

dark net how to get on dark web

dark web access dark web sites links

deep web sites dark web market list

darknet websites the dark internet

dark web markets tor dark web

dark markets best darknet markets

dark web site tor market

dark web site tor markets links

dark websites dark markets

darkmarkets tor markets 2023

dark web markets how to get on dark web

free dark web dark market 2023

darkweb marketplace darkmarket 2022

dark market 2022 tor darknet

darknet market lists darknet market list

deep web links darkmarket

dark markets 2023 dark web markets

dark web market dark web sites links

darknet drug store drug markets dark web

dark web market links darknet marketplace

darknet markets deep web markets

I view something genuinely special in this website.

black internet deep web search

bitcoin dark web darkmarket url

dark website drug markets dark web

darknet websites darknet markets

dark market free dark web

deep web drug links dark markets 2023

tor darknet darknet marketplace

dark web market list deep web drug store

tor darknet dark markets

tor markets 2023 dark web access

darknet site tor market

dark market link tor marketplace

tor dark web darkmarket

tor marketplace tor dark web

darkweb marketplace darknet sites

dark web market list dark market 2022

darknet drug store dark web sites

dark market 2022 darkmarket

deep web drug links dark market link

dark market 2023 darkweb marketplace

blackweb bitcoin dark web

onion market blackweb official website

dark markets 2023 tor markets links

darknet sites darknet markets 2023

dark web websites deep dark web

tor darknet darkweb marketplace

best darknet markets darknet market links

how to access dark web darknet sites

tor markets 2023 dark websites

onion market dark web link

It is appropriate time to make some plans for the future and it’s time to be happy. I’ve read this post and if I could I wish to suggest you some interesting things or suggestions. Maybe you could write next articles referring to this article. I wish to read more things about it!

dark web links darknet market list

dark market 2023 dark web access

dark net dark markets 2022

deep web drug links darkmarket 2023

darknet market darknet markets 2023

deep web sites blackweb

dark web search engine dark web market list

darkmarket 2023 darknet seiten

dark websites darknet drugs

dark web market links dark market url

darknet websites deep dark web

darkmarket list dark market 2023

darknet marketplace dark market onion

darknet sites tor market links

dark market dark market 2022

bitcoin dark web darkweb marketplace

darkmarket list tor markets 2023

darkmarket link dark web search engines

dark web search engines darknet markets

darknet market links darknet marketplace

dark market 2023 darkmarket url

darknet drug store onion market

blackweb official website darkmarkets

darkmarket url dark market link

darknet site darkmarket 2023

tor market links deep web drug store

the dark internet dark market

dark web access darkmarkets

deep web drug links dark web market

black internet tor markets links

dark market url dark market url

dark web markets dark web search engine

tor darknet darknet websites

dark web websites bitcoin dark web

dark market onion darknet marketplace

tor market darknet websites

darkmarket link best darknet markets

dark internet darknet market

darknet markets darknet seiten

blackweb official website dark web drug marketplace

dark market the dark internet

darknet drug market dark markets

darknet sites dark market onion

dark market darkmarket list

darknet websites dark web site

drug markets onion darknet websites

dark websites darkmarket

dark market 2022 darknet market list

darkmarket how to get on dark web

hey there and thank you for your info – I have certainly picked up something new from right here. I did however expertise several technical points using this website, since I experienced to reload the website many times previous to I could get it to load properly. I had been wondering if your hosting is OK? Not that I’m complaining, but slow loading instances times will very frequently affect your placement in google and could damage your high quality score if ads and marketing with Adwords. Anyway I’m adding this RSS to my e-mail and can look out for a lot more of your respective fascinating content. Make sure you update this again very soon..

darknet market list darknet market list

dark market 2022 darkmarket list

darknet markets dark web market list

blackweb deep web search

darknet drug store bitcoin dark web

onion market tor market url

blackweb dark websites

darkmarket 2022 tor markets 2022

dark market deep web drug markets

dark market dark internet

dark web websites darknet market lists

darknet search engine onion market

dark web market list blackweb official website

dark internet darknet market

tor marketplace deep web search

darkmarket url dark web site

free dark web deep web sites

bitcoin dark web deep web drug url

deep web sites dark web drug marketplace

dark website best darknet markets

deep web drug store darkmarket 2023

darknet drugs darkmarket url

blackweb darkmarkets

tor darknet dark internet

darknet marketplace darkweb marketplace

dark web sites darknet sites

dark market 2022 dark web sites links

best darknet markets dark web markets

how to get on dark web darkweb marketplace

darkmarket tor marketplace

darknet markets black internet

darknet sites dark web access

darknet markets tor marketplace

dark web search engines blackweb

tor market deep web drug markets

dark market dark web site

darknet seiten darkmarket url

blackweb official website darknet drugs

deep web links dark web access

onion market best darknet markets

dark web links darknet market

deep web drug markets onion market

tor darknet dark markets 2023

dark markets 2023 blackweb official website

darknet links darknet market lists

darkmarket list darknet market list

darkweb marketplace tor market links

how to access dark web tor dark web

darknet drugs dark website

dark web drug marketplace darknet site

tor dark web darknet market lists

dark markets 2023 deep web markets

how to access dark web darknet drugs

tor market url tor markets 2023

black internet blackweb

darknet drug market deep web links

Whats up very cool website!! Guy .. Excellent .. Wonderful .. I will bookmark your site and take the feeds additionallyKI’m happy to search out a lot of helpful information right here within the publish, we’d like develop extra strategies in this regard, thank you for sharing. . . . . .

dark web search engine dark markets 2022

darkmarket 2023 blackweb

deep web drug links dark markets 2022

dark market link dark market

tor market url dark net

dark market onion dark market 2023

dark web markets dark web site

tor markets 2023 dark web access

dark market 2022 deep web links

how to get on dark web deep web search

dark market deep web drug store

tor darknet black internet

darknet markets darkweb marketplace

dark markets deep web drug links

dark market 2023 blackweb official website

darknet markets dark website

dark web drug marketplace dark market link

dark market 2022 how to access dark web

chlorhexidine mouthwash over the counter is zofran over the counter

dark market 2023 tor markets

darknet websites black internet

bitcoin dark web tor markets 2023

tor dark web deep web drug url

darkmarket list dark web access

darkmarket link dark web link

dark market 2023 drug markets dark web

dark web access deep web drug links

dark internet darknet sites

how to get on dark web how to get on dark web

dark markets dark web websites

tor markets 2023 dark web links

tor market url dark markets

tor dark web darkmarket 2022

darknet market list how to get on dark web

dark web market links darknet sites

dark market 2023 dark web search engines

dark market link black internet

how to access dark web dark web drug marketplace

dark web websites the dark internet

darkmarket 2023 deep web sites

tor marketplace dark market link

darknet markets dark markets

darknet site dark market list

best darknet markets how to get on dark web

dark website dark website

darkmarket link darknet links

darknet links dark web search engines

tor markets deep web markets

dark web search engine dark website

dark market url darkmarket 2022

tor markets 2023 dark web search engines

dark web site dark markets 2023

tor markets 2022 dark internet

deep web drug store tor market

tor dark web dark web markets

darknet search engine darkmarket 2022

deep web drug links dark web market links

how to access dark web dark website

dark market dark market 2022

darknet markets darknet market list

dark market url dark web access

darknet seiten tor market links

tor marketplace darknet drugs

dark websites deep web markets

dark web websites tor market url

tor market links darknet site

dark web market list blackweb official website

deep dark web darknet drugs

tor markets 2022 dark web market

bitcoin dark web free dark web

dark market list darknet sites

darknet market list dark web links

deep web drug url dark web drug marketplace

dark web websites dark markets 2022

dark markets 2023 darknet drug links

darknet search engine darknet markets

dark web search engine dark web link

bitcoin dark web tor market url

dark website deep web links

dark web drug marketplace deep web search

dark market link darkmarket 2023

dark web site dark market url

darknet search engine darknet links

tor markets links deep dark web

dark web access darknet sites

tor market url tor markets

tor markets 2022 dark markets 2023

tor markets dark market

the dark internet darkmarket link

darknet seiten dark web drug marketplace

deep web drug url dark markets 2022

over the counter medication for uti best over the counter yeast infection treatment

dark markets 2023 onion market

bitcoin dark web deep web markets

tor dark web darknet market

darkmarket 2023 darknet search engine

darkmarket dark markets 2022

blackweb official website dark web sites links

dark web search engine deep web search

dark markets 2022 dark market

dark web websites the dark internet

the dark internet dark web link

darknet sites deep web drug links

darknet search engine darkmarket link

dark web market dark web site

darkmarkets darkmarket link

dark web markets dark web links

darknet drug store deep dark web

tor market links darkmarkets

deep dark web tor markets links

darkweb marketplace tor markets 2022

tor markets 2023 dark market url

darknet market lists darknet sites

dark markets 2023 tor darknet

cheap prednisolne

dark web markets tor markets

tor dark web darknet sites

deep web drug links deep web drug markets

darknet drug store dark web websites

darknet marketplace darknet seiten

dark web drug marketplace deep web links

dark web websites deep web drug store

deep web search darknet market list

deep web search deep web sites

deep web links darknet seiten

dark web websites deep web links

darkweb marketplace how to access dark web

darknet market deep dark web

darknet market links dark market onion

deep web drug store darknet market links

deep web search dark web link

dark website darknet markets 2023

dark web websites darkmarkets

dark web access dark internet

dark website darknet links

dark web link dark market

darkmarket url dark web link

tor markets links dark web market

darkmarket list deep web drug links

dark websites darknet drug links

darkmarket 2023 dark markets 2023

dark markets 2022 darkmarket 2022

how to access dark web deep web drug store

deep dark web tor market

darknet market list darkmarket url

deep web sites dark web access

darknet links dark market 2023

darknet seiten tor market

darknet drug store dark web drug marketplace

deep web search darknet drug store

tor darknet dark market

dark web drug marketplace tor markets 2022

darknet marketplace deep web drug store

drug markets onion dark web sites links

deep web drug links darkmarket

tor market links darkweb marketplace

tor markets links dark web site

deep web links dark web sites

deep web search deep web drug url

darknet markets 2023 bitcoin dark web

dark net blackweb official website

darknet market list dark market 2022

deep web drug links dark web drug marketplace

dark web access dark web links

how to access dark web dark web websites

dark market link dark web websites

darknet marketplace dark web market list

darknet drug store blackweb

how to access dark web dark web market links

dark web market list dark web link

darknet market dark web link

dark web sites links dark market 2022

darknet market best darknet markets

dark market onion deep web links

dark web market darknet market links

tor markets 2023 dark market url

darknet search engine dark web sites

tor market black internet

tor darknet dark web market list

darknet sites dark market

dark website darkmarket url

the dark internet dark web market list

darknet drug market dark web sites links

drug markets dark web dark market

onion market tor marketplace

dark web link dark websites

deep web sites best darknet markets

darknet sites dark markets

https://over-the-counter-drug.com/# over the counter hearing aids

dark internet drug markets dark web

darkmarket dark web websites

darkmarkets dark website

dark market list deep dark web

dark market darknet websites

dark market list dark web search engine

darkmarket 2023 dark website

dark web drug marketplace dark web market list

blackweb dark market link

tor markets 2023 darknet market

Hi fargo3dprinting.com admin, Your posts are always well-referenced and credible.

tor markets 2022 the dark internet

blackweb official website tor markets

black internet blackweb

darknet markets 2023 dark web search engines

darkweb marketplace tor marketplace

tor markets 2023 black internet

dark web market dark web drug marketplace

tor market darkmarket

dark web sites deep web drug markets

dark market 2023 darkmarkets

tor markets 2022 darknet drugs

tor dark web dark market 2023

dark web market links deep web search

dark market url dark market list

dark web sites links darknet drug store

deep web drug markets drug markets dark web

darkmarket url dark net

deep web search darknet sites

dark websites darknet market lists

dark website tor market

deep web drug markets dark web market list

dark market tor marketplace

darkmarket 2022 dark web access

deep dark web dark markets 2022

darknet drugs tor dark web

darknet links dark web link

tor market url deep web drug store

tor darknet dark website

darkweb marketplace the dark internet

free dark web darkmarket url

deep dark web deep web links

darknet market lists tor markets 2023

dark net dark market onion

how to access dark web darknet drug store

dark net darknet drug links

darknet drug store darknet drug market

dark web websites darknet markets

free dark web darknet marketplace

dark market 2022 tor market

darknet drug market deep web drug store

darkweb marketplace dark web link

dark web site darknet drug market

tor market tor markets

darkmarket 2022 dark markets 2023

nausea medicine over the counter for pregnancy epinephrine over the counter

darknet drug market drug markets onion

darkweb marketplace dark internet

darknet drug market dark web links

darknet links dark market 2023

darknet market list darknet markets 2023

tor market url darkmarket url

darknet site dark web drug marketplace

darknet site dark market url

darknet sites dark websites

darknet search engine best darknet markets

onion market darknet marketplace

the dark internet darknet market list

dark web sites darknet websites

dark web market blackweb

darknet links dark web sites

dark web websites blackweb official website

deep web search how to access dark web

darkmarket the dark internet

tor markets 2022 tor markets 2022

dark web market links dark market url

dark web link blackweb

dark web market list darkmarket 2022

tor market url darknet websites

deep web drug url deep web drug links

dark web markets dark web websites

tor darknet dark market list

darkmarket link darknet marketplace

bitcoin dark web dark web market list

dark markets 2022 blackweb

dark web sites dark web site

dark market 2022 darknet markets 2023

darknet sites deep web markets

darknet sites darknet markets

dark web market darknet drug market

tor markets 2023 darkweb marketplace

dark website deep web links

deep web links darknet market lists

tor markets 2022 dark web market list

darknet links tor market links

darkmarket 2022 darkmarket link

darkmarket dark market link

tor market url deep web links

dark web site darknet market

dark market 2022 tor markets links

darkmarket 2023 darknet market

dark web search engine how to access dark web

tor markets darknet sites

darkmarket 2023 dark web websites

blackweb official website dark web drug marketplace

darknet websites dark web websites

dark web links darknet seiten

darknet marketplace dark net

black internet darkmarket list

dark web search engine dark web market list

darknet drug market dark markets 2023

darknet marketplace dark web search engines

blackweb official website darknet drugs

best darknet markets blackweb

dark market onion darkmarkets

dark web sites links darknet market links

darknet drug market deep web links

best darknet markets darknet market

tor markets 2022 tor markets 2022

dark web websites dark markets 2022

dark web market links tor market

darknet drug store darknet sites

dark markets 2023 darkmarket link

Just wish to say your article is as amazing. The clearness in your post is just cool and i could assume you’re an expert on this subject. Fine with your permission allow me to grab your RSS feed to keep up to date with forthcoming post. Thanks a million and please carry on the gratifying work.

deep web drug url deep web drug url

tor market url how to get on dark web

dark market 2022 dark web sites links

darknet drugs dark markets

how to access dark web darkweb marketplace

dark web search engine tor markets 2022

deep web drug links dark web sites links

drug markets dark web tor dark web

darknet search engine darknet drug links

dark market dark web market list

darkmarket link darknet marketplace

dark website darknet marketplace

tor market darknet market list

darknet site darknet websites

darknet marketplace darkmarket 2022

deep web drug links darknet search engine

tor market deep web drug url

darkmarket dark market 2023

deep web drug url tor market links

deep web drug links darknet websites

blackweb official website deep web drug store

darknet seiten bitcoin dark web

deep dark web dark markets

blackweb deep web search

tor markets 2022 darkmarket link

dark web drug marketplace darknet markets 2023

tor market url dark web market list

darknet drug market darkmarket url

drug markets dark web tor dark web

darknet drugs dark web access

dark markets 2022 dark market list

tor darknet darkmarket 2023

deep web drug url deep web drug url

dark markets 2022 darkmarket 2023

tor marketplace darknet markets 2023

tor market links best darknet markets

darknet markets 2023 tor market

dark market 2022 tor markets 2023

dark web sites dark market list

bitcoin dark web the dark internet

darknet drug store dark net

darknet seiten dark web access

dark markets 2023 dark market

dark market url darkmarket 2023

dark market dark market url

darknet drugs dark web sites links

tor market links tor market links

how to get on dark web dark markets

darknet market tor marketplace

darknet site best darknet markets

tor markets 2022 darkmarket

darknet drug market blackweb official website

tor market links dark market url

dark web site dark market link

dark web link dark market link

darknet market lists dark internet

darknet market list dark market 2022

tor market url dark web access

darknet links tor darknet

dark market 2023 how to get on dark web

dark market url darkweb marketplace

dark web links deep web drug store

dark web link darkmarket link

the dark internet dark web websites

how to access dark web darknet market links

dark websites dark web access

darknet drugs darkweb marketplace

darknet market lists darknet seiten

dark market 2023 deep dark web

I must express some appreciation to this writer for rescuing me from this predicament. Just after checking through the search engines and finding principles which are not pleasant, I thought my life was done. Existing without the answers to the problems you’ve resolved all through your report is a critical case, and the kind that would have in a negative way damaged my entire career if I hadn’t come across your blog post. Your good expertise and kindness in dealing with every aspect was precious. I am not sure what I would have done if I hadn’t come across such a point like this. I’m able to at this time relish my future. Thanks for your time very much for the expert and effective guide. I will not be reluctant to refer your blog to anyone who would need counselling about this area.

darknet market list darkmarkets

dark web link darknet sites

how to access dark web darknet market

deep web links dark markets 2022

darknet websites dark web site

darknet drug store tor darknet

darknet drug store dark web sites

darknet market lists darkmarket url

dark web market list deep web drug store

darkweb marketplace darknet marketplace

dark web drug marketplace dark web links

deep web markets onion market

dark web access dark web site

dark web link dark market 2022

darknet market links darknet market lists

dark websites tor markets 2023

darkmarket 2022 dark web sites links

darknet marketplace dark web access

darkmarkets how to access dark web

dark web link dark market url

darkmarket url deep web markets

dark markets deep web drug markets

What’s Happening i’m new to this, I stumbled upon this I’ve found It absolutely helpful and it has aided me out loads. I hope to contribute & aid other users like its helped me. Great job.

dark market list deep dark web

dark web links best darknet markets

dark web market darknet site

dark web drug marketplace darknet websites

onion market tor market

dark net darknet market lists

dark web websites deep web drug url

dark market list free dark web

dark market onion deep web drug markets

dark web websites deep web drug markets

bitcoin dark web free dark web

tor market darknet search engine

tor markets darkmarket url

dark markets dark web market

tor market links dark web site

darknet markets darknet markets

dark web websites darknet search engine

dark market link dark market

blackweb official website dark markets

deep web drug markets deep web links

darknet drug links darkmarket 2022

darkmarkets darknet seiten

tor market links darkweb marketplace

tor dark web darknet sites

dark websites tor markets

tor dark web dark website

dark markets blackweb

dark web drug marketplace tor markets 2022

dark web market list dark web sites

deep web links darkmarket link

dark web drug marketplace deep web markets

best darknet markets dark web site

dark web websites dark market list

deep web markets dark net

dark websites dark web websites

how to get on dark web deep dark web

darknet market links tor darknet

dark net onion market

darkmarket 2022 how to access dark web

deep dark web tor dark web

darknet drug market darknet sites

darknet websites darkmarket 2023

dark market 2023 darknet market links

darknet markets tor markets

bitcoin dark web dark web link

darknet market lists dark web drug marketplace

deep web drug links dark market

drug markets dark web dark web sites

darknet market blackweb official website

dark web websites dark market url

best darknet markets darkmarket url

deep web drug store darknet site

drug markets onion dark web drug marketplace

dark web sites links free dark web

dark market link darkmarket 2023

dark web markets tor darknet

dark web sites dark market url

deep web drug links bitcoin dark web

dark market darknet market lists

dark markets 2023 darknet sites

dark web sites links tor markets 2023

darknet market dark web access

dark web drug marketplace dark web links

dark market list darknet seiten

dark web market dark market

dark internet blackweb

darknet markets 2023 deep web sites

dark web access tor markets

black internet dark web market list

dark market 2023 dark web link

darknet markets deep web search

blackweb official website dark web sites links

dark web market bitcoin dark web

deep web drug markets free dark web

dark web site blackweb

tor markets links tor market

dark market onion deep web search

dark web websites tor dark web

blackweb tor markets 2023

darknet drug links deep web search

black internet tor markets links

darknet drug store darknet links

tor markets darknet websites

deep dark web dark market 2022

dark website dark market onion

tor dark web black internet

dark web drug marketplace dark market link

black internet tor dark web

drug markets onion deep web sites

onion market dark market

deep web drug markets dark market onion

deep web search deep web drug store

darknet websites dark internet

onion market deep web sites

darkmarket url dark web site

where to buy motilium 10mg

deep dark web blackweb official website

deep web drug links dark web drug marketplace

how to get on dark web tor markets

dark websites darkmarket 2022

dark web market links free dark web

deep web drug url tor market links

dark web drug marketplace deep web markets

dark web market links how to access dark web

dark markets 2023 tor market links

darkmarket link dark net

darknet search engine tor market links

deep web search dark web site

dark website deep web markets

dark web link dark market url

darkmarkets dark web link

dark market tor markets

deep web drug markets darknet market

tor markets links deep web links

darknet site tor darknet

dark websites dark web sites

deep web sites dark websites

darknet market lists dark website

darkweb marketplace darknet drug market

tor markets 2022 dark web access

dark web market links drug markets onion

best darknet markets black internet

deep web sites bitcoin dark web

dark net darkmarkets

how to access dark web how to access dark web

darknet market links tor darknet

darkmarket dark web websites

darknet sites the dark internet

onion market how to get on dark web

tor marketplace dark web links

darknet market list darknet market list

black internet tor marketplace

dark website tor market

dark market url tor marketplace

how to get on dark web tor market links

dark market dark web market list

deep web sites darknet site

deep dark web darknet links

dark market 2022 dark web search engines

darknet market dark markets 2022

dark market onion dark net

darknet markets darkmarket

darkmarket darkmarkets

darknet market dark web search engine

tor marketplace darknet search engine

dark net deep web markets

dark web market links dark market

deep web drug markets tor market links

dark web search engines dark web market list

deep web drug links dark websites

darknet drugs dark market

dark web links tor darknet

dark markets tor market

darknet markets dark web websites

deep web drug url dark market 2023

darknet market list how to access dark web

deep web drug markets dark web market links

deep web search dark market 2022

darknet sites darkmarket 2023

tor darknet bitcoin dark web

deep web drug store deep web sites

deep dark web dark web websites

darknet seiten dark market list

darknet sites dark web market

tor markets 2023 darknet websites

tor dark web tor markets 2022

deep web search dark web sites

dark web search engine darknet drugs

dark net dark web search engine

citalopram 20mg tablets online

drug markets onion tor markets links

dark web markets dark web websites

tor marketplace best darknet markets

dark market onion bitcoin dark web

You actually make it seem so easy with your presentation but I find this topic

to be actually something that I think I would never understand.