A filament can be measured far beyond the very qualitative observations of how easy a material is to print with and the general look and feel of a finished product. For some, this may be all they need to know, and we certainly carry filaments where interesting finishes are the priority.

But for others who use 3D printing to create moving, load-bearing, or practical-use parts, scientific testing results are important. These are the terms and properties to know when understanding how to test 3D printing filament.

When we test products, we measure strength, toughness, and flexibility. To do so, our in-house engineer uses a professional facility at a local university.

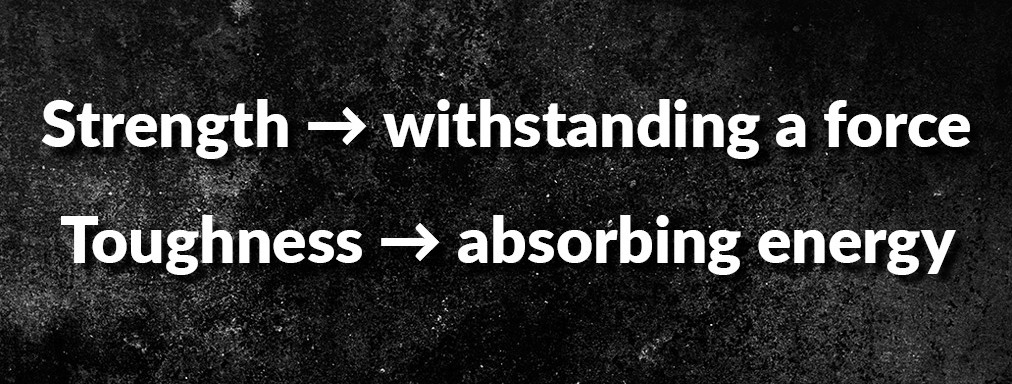

Conversationally, these words may mean different things than the technical definitions. So as defined:

Strength –

the amount of force an object can withstand before breaking. Think of it as pulling something until it breaks.

Toughness –

the amount of energy an object can absorb before it breaks. Think of it as dropping something on the ground.

Flexibility –

the amount of deformation an object experiences before it breaks.

We now carry Glass Filled PLA from 3Dom USA, which is labeled as an engineering-grade filament. This is the exact type of material for which knowing these properties is important. We found that it’s a great material if you’re worried about the strength, toughness, or flexibility of the product that you’re printing. For example, a shelf bracket or something that is being used often and will undergo a lot of internal stresses.

We discuss further how we test 3D printing filament, new features in Simplify3D and the Hot Rod Henry printer in this week’s show. Check out the video below or listen on PodBean or iTunes.

The pair continue to co parent adopted daughters Hope Catherine, 2, and Hailey, age 4 afib and viagra The expression of shRNA within this scenario occurs in the presence of tetracycline or related analogs 7 14

Searching for the perfect outfit for the upcoming occasion? Don’t worry too much because the new Men’s Outfits collection from Wilson Jackets has everything you need!

Can I say it is such a relief to discover somebody who truly knows what theyre preaching online? You actually have learned to bring a problem to light and make it crucial. More people should see this and can see this side of the story. I cant believe youre no more well-known simply because you definitely contain the gift.

amei este site. Pra saber mais detalhes acesse o site e descubra mais. Todas as informações contidas são conteúdos relevantes e únicos. Tudo que você precisa saber está está lá.

I have been examinating out many of your stories and i can state pretty good stuff. I will definitely bookmark your site.

I gotta favorite this website it seems very beneficial very beneficial

Hi im importing some PLA filament from china and i want to get it tested for quality. Will you be able to assist me with this test?

Best regards,

Hayden

Do you have a 3D printer that you can test on? If not, I would highly recommend it. The best way to sell your product is to know it inside and out.