As an engineer, when I use a 3D printer, I use it to print functional parts. Most of the time these parts have to withstand some sort of force or impact in order to function properly. PLA is normally good enough and gets the job done but if I need a tougher, more flexible material, I used to reach for my spool of ABS. Not anymore. Here’s a engineer’s filament review.

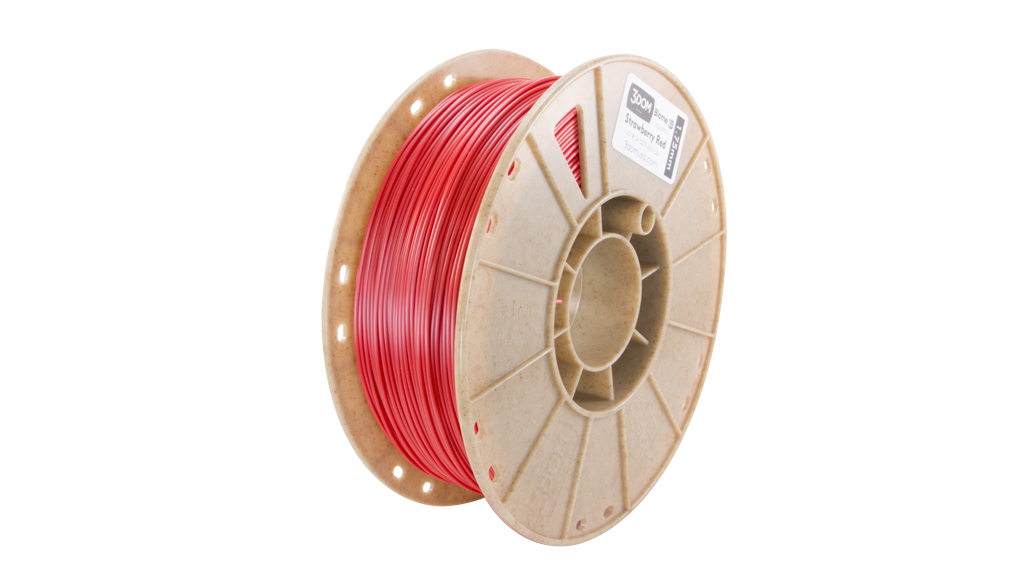

When I first saw a spool of Biome3D I noticed that it had a luster and felt very smooth. I was told that it had similar mechanical properties to ABS but without the odor and warping issues. I was intrigued to say the least.

My first few test prints came out well but they stuck to the gaffer’s tape build surface I was using and I couldn’t for the life of me remove the raft from the part. After fiddling with the print settings and going from gaffer’s tape to bare acrylic and finally to painters tape I got my first good print. The final product had a great look and feel, and sure enough, it was much more flexible than the PLA I was used to using and possibly more flexible than ABS.

Biome3D definitely has its uses, and like other plastic and composites, it may not always be the best for every application. A few things to note about Biome3D: it has temperature characteristics more similar to PLA than ABS so it might not be a drop in replacement if you need the extra thermal protection. Also, many people like the ability to use acetone to smooth and adhere ABS parts. Acetone works like this because it is a solvent for ABS, but it won’t work on Biome3D. Unless I am using ABS for one of these two reasons, I will pick Biome3D every time from here on out.

I have yet to print a part in Biome3D that has had more than minor warping issues. It also has great interlayer adhesion – I have yet to have a part delaminate while on the printer of after. This leads to a part that is strong, even in the vertical dimension.

Like I said before, I am an engineer, not an artist. That doesn’t mean that Biome3D can’t be used because of its appearance. Biome3D has one of the best finishes I have seen on a 3D printed part. Once I got the settings dialed in on my printer, my completed parts had a very consistent surface finish and were very smooth. Printing on a heated bed with no raft leads to a very nice bottom surface as well.

One of my responsibilities at Fargo 3D Printing is to do materials testing. I have access to an electromechanical load frame (the same one used by other companies in the plastic industry) where I do tensile testing of the different filaments that we carry. Unlike the rest of the industry that uses injection molded samples for their tests, I 3D print my samples (at 100% infill) to get data that more closely represents how the filament will be used. Based on my testing, I found that Biome3D is 6 times more flexible than PLA and has an impact toughness of nearly 110% of PLA. This is why Biome3D is more desirable in applications where an impact or cyclical forces will be the norm, i.e. cell phone cases, gears, etc. This doesn’t mean that Biome3D is stronger than PLA, and in fact has only about 87% the strength of PLA, but this only matters in applications where a large constant load will be applied to a part which, at least for me, is rarely the case with a printed part.

After I do property testing on a new material, I get to mess around with finding the best print settings for it. I started working on a Makerbot Replicator 2 (i.e. no heated bed). As I alluded to before, Biome3D sticks to itself and other materials very readily. I started with printing on gaffer’s tape which is what we at Fargo 3D Printing use for nearly all of our printers. Biome3D stuck to it extremely well, so well that I couldn’t remove it without tearing up the tape. I moved to a bare acrylic surface which was a bit better than the gaffer’s tape, but I ended up scratching the build plate a lot which could lead to bad prints down the line. I finally settled on good ol’ blue painters tape and it seemed to do the trick. The only issue I had with it was that the tape had a tendency of pulling away from the build surface so I layered blue tape on top of gaffer’s tape and that finally got me to the best prints so far.

When not using a heated bed, I print with a raft. In order to get the raft to be removed from the part while still getting a good bottom surface finish, I had to increase the distance between the raft and the part. In Makerbot’s slicer software, this is the Raft-Model Spacing property. Similar names are used in other slicing software, but it all means the same thing: the distance between the last layer of the raft and the first layer of the part. In Makerbot Desktop, I had to change the property from the default 0.23mm all the way up to 0.27mm before the part would separate.

On our Lulzbot Mini, I print directly on the included PEI build surface with no raft and a bed temperature of around 40 degrees Celsius.

Finally let me talk about print speeds and temps. For the most part, I print at 200 degrees Celsius on any machine but have gotten successful prints anywhere from 180 to 220. I generally leave the print speeds to the default or a standard PLA setting and only change them if the geometry of the part requires fiddling with these settings.

Overall, Biome3D is an easy to print with material that is tough and flexible and has a great surface finish.

— Zach Triplett is Fargo 3D Printing’s in-house engineer. See some of his work like the Overhead Spool Holder and the MakerBot Replicator 5th Gen Spool Holder on Thingiverse.

Loving the info on this web site, you have done outstanding job on the articles.

I’m impressed, I must say. Rarely do I come across a blog that’s equally educative and engaging, and without a doubt, you’ve hit the nail on the head. The issue is something that too few men and women are speaking intelligently about. Now i’m very happy that I stumbled across this in my hunt for something regarding this.

That is really fascinating, You are an overly skilled blogger. I have joined your feed and look ahead to in search of more of your fantastic post. Additionally, I’ve shared your web site in my social networks!

Hi, I do believe this is a great blog. I stumbledupon it 😉 I will come back once again since i have bookmarked it. Money and freedom is the greatest way to change, may you be rich and continue to guide other people.

After looking over a number of the blog articles on your web site, I seriously like your technique of writing a blog. I saved it to my bookmark webpage list and will be checking back soon. Take a look at my web site too and tell me your opinion.

whoah this blog is wonderful i like studying your posts. Stay up the good work! You already know, many individuals are hunting round for this information, you can help them greatly.

I think this internet site holds some very superb info for everyone :D. “We rarely think people have good sense unless they agree with us.” by Francois de La Rochefoucauld.

Great article. I am facing many of these issues as well..

Everything is very open and very clear explanation of issues. was truly information. Your website is very useful. Thanks for sharing.

This is a topic which is near to my heart… Best wishes! Where can I find the contact details for questions?

you have a great blog here! would you like to make some invite posts on my blog?

You have observed very interesting details ! ps decent web site.

What i do not realize is actually how you’re not really much more well-liked than you might be right now. You’re very intelligent. You realize thus considerably relating to this subject, made me personally consider it from numerous varied angles. Its like men and women aren’t fascinated unless it’s one thing to do with Lady gaga! Your own stuffs outstanding. Always maintain it up!

Interesting article. It is very unfortunate that over the last years, the travel industry has already been able to to take on terrorism, SARS, tsunamis, bird flu, swine flu, as well as the first ever true global tough economy. Through all this the industry has really proven to be strong, resilient and dynamic, locating new approaches to deal with difficulty. There are always fresh troubles and opportunity to which the market must again adapt and react.

https://zithromax.science/# how to get zithromax online

Enjoyed looking through this, very good stuff, regards.

I should say also believe that mesothelioma is a rare form of cancer malignancy that is commonly found in those previously familiar with asbestos. Cancerous tissue form inside mesothelium, which is a safety lining which covers most of the body’s areas. These cells typically form inside the lining from the lungs, stomach, or the sac that really encircles one’s heart. Thanks for expressing your ideas.

Pretty nice post. I just stumbled upon your weblog and wanted to say that I have really enjoyed browsing your blog posts. After all I?ll be subscribing to your feed and I hope you write again very soon!

This is a good tip especially to those new to the blogosphere. Simple but very precise info… Thanks for sharing this one. A must read post!

After examine a couple of of the weblog posts in your website now, and I actually like your way of blogging. I bookmarked it to my bookmark website record and shall be checking back soon. Pls take a look at my website online as properly and let me know what you think.

Many thanks for this article. I would also like to state that it can often be hard when you find yourself in school and simply starting out to initiate a long credit score. There are many students who are just trying to live and have a good or positive credit history can often be a difficult matter to have.

Pretty great post. I just stumbled upon your weblog and wanted to say that I’ve really enjoyed surfing around your blog posts. After all I will be subscribing on your feed and I am hoping you write again soon!

I was able to find good advice from your blog posts.

It is really a great and useful piece of information. I am glad that you shared this helpful information with us. Please keep us informed like this. Thank you for sharing.

Pretty! This was a really wonderful article. Thank you for providing this information.

best over the counter skin tag removal over the counter ed medication

You need to take part in a contest for top-of-the-line blogs on the web. I will advocate this web site!

I?ve read several good stuff here. Certainly worth bookmarking for revisiting. I wonder how a lot attempt you put to make any such wonderful informative site.

I just like the helpful information you provide for your articles. I will bookmark your blog and take a look at once more here frequently. I am moderately certain I?ll learn many new stuff right right here! Best of luck for the following!

Great work! This is the type of info that should be shared around the internet. Shame on the search engines for not positioning this post higher! Come on over and visit my web site . Thanks =)

over the counter oral thrush treatment best over the counter weight loss pills

Right here is the right website for everyone who hopes to find out about this topic. You know a whole lot its almost tough to argue with you (not that I personally would want to…HaHa). You certainly put a fresh spin on a topic that’s been discussed for a long time. Excellent stuff, just wonderful.

Wow! This can be one particular of the most useful blogs We have ever arrive across on this subject. Actually Magnificent. I am also a specialist in this topic so I can understand your hard work.

My brother recommended I might like this web site. He was totally right. This post actually made my day. You cann’t imagine simply how much time I had spent for this info! Thanks!

I like the valuable info you provide in your articles. I?ll bookmark your blog and check again here regularly. I am quite certain I?ll learn a lot of new stuff right here! Good luck for the next!

One thing I want to say is that car insurance termination is a horrible experience so if you’re doing the right things being a driver you’ll not get one. Many people do obtain the notice that they have been officially dropped by their particular insurance company and many have to struggle to get supplemental insurance after a cancellation. Cheap auto insurance rates are usually hard to get after having a cancellation. Having the main reasons concerning the auto insurance cancellation can help drivers prevent sacrificing one of the most significant privileges out there. Thanks for the suggestions shared by your blog.

I appreciate, cause I found just what I was looking for. You’ve ended my four day long hunt! God Bless you man. Have a nice day. Bye

F*ckin? remarkable issues here. I am very glad to peer your article. Thank you a lot and i’m looking forward to touch you. Will you kindly drop me a e-mail?

Having read this I believed it was extremely informative. I appreciate you taking the time and energy to put this article together. I once again find myself spending way too much time both reading and leaving comments. But so what, it was still worthwhile.

WONDERFUL Post.thanks for share..more wait .. ?

I want to to thank you for this wonderful read!! I definitely enjoyed every bit of it. I have you saved as a favorite to check out new stuff you post…

I think this web site holds some real superb info for everyone : D.

over the counter tapeworm treatment for dogs over the counter eye drops for pink eye

I need to to thank you for this very good read!! I certainly enjoyed every little bit of it. I’ve got you saved as a favorite to look at new things you post…

Would love to incessantly get updated great web blog! .

I’m very pleased to find this page. I wanted to thank you for ones time due to this wonderful read!! I definitely really liked every little bit of it and I have you bookmarked to look at new things on your web site.

Greetings! Very useful advice in this particular post! It is the little changes that will make the greatest changes. Thanks a lot for sharing!

I genuinely enjoy looking at on this internet site, it contains fantastic articles.

walgreens sleep aids over the counter male uti treatment over the counter

Hello, you used to write magnificent, but the last several posts have been kinda boring… I miss your great writings. Past several posts are just a little out of track! come on!

Insurance premiums from many insureds are used to fund accounts reserved for later payment of claims – in principle for a relatively few claimants – and for overhead prices.

Great article. It is rather unfortunate that over the last 10 years, the travel industry has had to fight terrorism, SARS, tsunamis, flu virus, swine flu, as well as the first ever entire global economic depression. Through everything the industry has proven to be sturdy, resilient as well as dynamic, acquiring new strategies to deal with hardship. There are often fresh issues and chance to which the industry must again adapt and react.

I needed to thank you for this wonderful read!! I absolutely loved every bit of it. I’ve got you bookmarked to check out new things you post…

Excellent post. I was checking constantly this blog and I’m impressed! Very useful info specially the last part 🙂 I care for such info much. I was looking for this certain info for a long time. Thank you and best of luck.

Wow, amazing blog layout! How long have you been blogging for? you made blogging look easy. The overall look of your website is wonderful, let alone the content!

Next time I read a blog, Hopefully it doesn’t fail me as much as this particular one. I mean, Yes, it was my choice to read through, but I genuinely believed you would have something useful to say. All I hear is a bunch of moaning about something you can fix if you were not too busy seeking attention.

I blog often and I really thank you for your information. The article has really peaked my interest. I am going to book mark your website and keep checking for new details about once a week. I opted in for your RSS feed as well.

Aw, this was a very nice post. In thought I want to put in writing like this moreover ? taking time and actual effort to make an excellent article? but what can I say? I procrastinate alot and on no account seem to get something done.

Thanks for your posting. One other thing is that if you are promoting your property alone, one of the troubles you need to be alert to upfront is how to deal with house inspection reviews. As a FSBO supplier, the key towards successfully transferring your property as well as saving money about real estate agent income is expertise. The more you recognize, the smoother your home sales effort will probably be. One area where by this is particularly significant is information about home inspections.

Thanks for the suggestions you are revealing on this weblog. Another thing I want to say is always that getting hold of duplicates of your credit file in order to look at accuracy of each and every detail could be the first measures you have to accomplish in repairing credit. You are looking to cleanse your credit reports from detrimental details problems that ruin your credit score.

Do you mind if I quote a couple of your articles as long as I provide credit and sources back to your website? My blog site is in the exact same niche as yours and my visitors would really benefit from some of the information you provide here. Please let me know if this ok with you. Thanks a lot!

Unquestionably imagine that that you said. Your favourite reason appeared to be at the net the simplest factor to have in mind of. I say to you, I certainly get irked while people think about concerns that they just don’t recognise about. You controlled to hit the nail upon the top and also defined out the entire thing with no need side effect , other people can take a signal. Will probably be again to get more. Thanks

The following time I read a weblog, I hope that it doesnt disappoint me as a lot as this one. I mean, I do know it was my choice to read, however I truly thought youd have one thing interesting to say. All I hear is a bunch of whining about one thing that you might fix when you werent too busy searching for attention.

over the counter best over the counter nausea medicine

Thank you sharing these kind of wonderful content. In addition, the optimal travel in addition to medical insurance system can often ease those problems that come with visiting abroad. A new medical crisis can quickly become extremely expensive and that’s certain to quickly place a financial burden on the family’s finances. Putting in place the ideal travel insurance package deal prior to setting off is definitely worth the time and effort. Cheers

over the counter blood thinners best over the counter cold medicine

https://over-the-counter-drug.com/# uhc over the counter essentials 2019

Today, I went to the beachfront with my children. I found a sea shell and gave it to my 4 year old daughter and said “You can hear the ocean if you put this to your ear.” She placed the shell to her ear and screamed. There was a hermit crab inside and it pinched her ear. She never wants to go back! LoL I know this is totally off topic but I had to tell someone!

Its like you read my mind! You appear to know so much about this, like you wrote the book in it or something. I think that you simply can do with a few to power the message home a bit, but other than that, that is magnificent blog. A great read. I will definitely be back.

Somebody essentially help to make seriously posts I would state. This is the first time I frequented your website page and thus far? I amazed with the research you made to create this particular publish incredible. Excellent job!

clobetasol cream over the counter best over-the-counter medicine for sinus infection

I believe that avoiding packaged foods is a first step to lose weight. They can taste great, but processed foods contain very little vitamins and minerals, making you consume more just to have enough vigor to get with the day. If you are constantly having these foods, transitioning to grain and other complex carbohydrates will make you to have more energy while eating less. Good blog post.

is viagra over the counter over the counter stocks

Yet another thing to mention is that an online business administration program is designed for people to be able to effortlessly proceed to bachelors degree courses. The Ninety credit diploma meets the other bachelor college degree requirements and when you earn your current associate of arts in BA online, you will have access to the modern technologies in this particular field. Several reasons why students need to get their associate degree in business is because they can be interested in this area and want to receive the general training necessary just before jumping in a bachelor diploma program. Thanks alot : ) for the tips you provide with your blog.

Dear fargo3dprinting.com webmaster, You always provide great insights.

You made a number of good points there. I did a search on the subject matter and found most persons will go along with with your blog.

You made some first rate points there. I regarded on the internet for the difficulty and located most individuals will go together with along with your website.

It’s really a great and useful piece of information. I am happy that you simply shared this helpful info with us. Please keep us informed like this. Thank you for sharing.

https://drugsoverthecounter.shop/# over the counter pills like viagra

This is the right blog for anyone who wants to find out about this topic. You realize so much its almost hard to argue with you (not that I actually would want…HaHa). You definitely put a new spin on a topic thats been written about for years. Great stuff, just great!

Hi there! This is my first visit to your blog! We are a collection of volunteers and starting a new project in a community in the same niche. Your blog provided us beneficial information to work on. You have done a outstanding job!

Some genuinely nice and utilitarian info on this site, too I believe the layout holds excellent features.

Major thanks for the article post. Much thanks again.

My website: cartoon porn

Thanks for the strategies presented. One thing I additionally believe is that credit cards giving a 0 apr often bait consumers along with zero monthly interest, instant acceptance and easy internet balance transfers, but beware of the real factor that will probably void the 0 easy street annual percentage rate as well as throw anybody out into the bad house rapidly.

In the awesome pattern of things you’ll receive a B- with regard to hard work. Where you misplaced us was in all the specifics. As as the maxim goes, details make or break the argument.. And that couldn’t be much more true right here. Having said that, let me tell you just what did give good results. Your writing is extremely convincing which is possibly why I am taking an effort in order to comment. I do not really make it a regular habit of doing that. Secondly, while I can notice a leaps in reason you make, I am not necessarily confident of exactly how you seem to connect the points which produce the actual conclusion. For right now I will yield to your position but wish in the foreseeable future you actually link your dots much better.

Today, considering the fast life style that everyone leads, credit cards have a huge demand throughout the market. Persons from every area are using credit card and people who are not using the card have made up their minds to apply for just one. Thanks for spreading your ideas about credit cards.

Terrific work! That is the type of information that are supposed to be shared across the net. Shame on the search engines for not positioning this put up upper! Come on over and seek advice from my website . Thank you =)

I like this web blog so much, bookmarked.

You have mentioned very interesting points! ps decent web site.

With every thing that seems to be building within this particular subject material, a significant percentage of points of view tend to be quite refreshing. Nevertheless, I appologize, but I can not subscribe to your entire idea, all be it stimulating none the less. It looks to everyone that your commentary are generally not entirely justified and in simple fact you are your self not entirely certain of your point. In any case I did take pleasure in reading through it.

Thanks for another informative website. Where else could I get that kind of information written in such an ideal way? I’ve a project that I am just now working on, and I have been on the look out for such information.

I have discovered that service fees for online degree specialists tend to be a terrific value. For example a full Bachelors Degree in Communication from The University of Phoenix Online consists of Sixty credits with $515/credit or $30,900. Also American Intercontinental University Online gives a Bachelors of Business Administration with a full program element of 180 units and a tuition fee of $30,560. Online studying has made having your diploma much simpler because you might earn the degree in the comfort of your dwelling place and when you finish working. Thanks for other tips I have really learned through the web site.

I have been checking out some of your articles and i can state pretty clever stuff. I will make sure to bookmark your blog.

Amazing blog! Is your theme custom made or did you download it from somewhere? A design like yours with a few simple tweeks would really make my blog shine. Please let me know where you got your theme. Thank you

I was suggested this web site via my cousin. I’m now not certain whether this post is written by means of him as no one else realize such particular approximately my trouble. You’re incredible! Thanks!

Muchos Gracias for your article.Really thank you! Cool.

My website: cartoon porn

okmark your weblog and check again here frequently. I’m quite sure I?ll learn many new stuff right here! Best of luck for the next!

Hi there, just became aware of your blog through Google, and found that it is really informative. I am going to watch out for brussels. I?ll appreciate if you continue this in future. Numerous people will be benefited from your writing. Cheers!

It?s hard to seek out knowledgeable folks on this topic, but you sound like you know what you?re talking about! Thanks

Este site é realmente fabuloso. Sempre que acesso eu encontro coisas diferentes Você também pode acessar o nosso site e descobrir detalhes! Conteúdo exclusivo. Venha saber mais agora! 🙂

I do believe all of the ideas you have presented on your post. They’re very convincing and will certainly work. Nonetheless, the posts are too short for novices. May you please prolong them a little from subsequent time? Thank you for the post.

You could certainly see your enthusiasm within the paintings you write. The arena hopes for even more passionate writers such as you who are not afraid to say how they believe. Always follow your heart.

It?s laborious to find educated people on this topic, however you sound like you know what you?re talking about! Thanks

I have recently started a site, the information you provide on this web site has helped me greatly. Thanks for all of your time & work. “Show me the man who keeps his house in hand, He’s fit for public authority.” by Sophocles.

I am really impressed with your writing skills and also with the layout on your weblog. Is this a paid theme or did you modify it yourself? Either way keep up the nice quality writing, it?s rare to see a great blog like this one today..

Thanks for some other informative web site. Where else may I am getting that kind of info written in such a perfect means? I have a venture that I am simply now running on, and I’ve been at the look out for such info.

Magnificent beat ! I wish to apprentice while you amend your site, how can i subscribe for a blog web site? The account helped me a acceptable deal. I had been a little bit acquainted of this your broadcast offered bright clear idea

This is the right webpage for anyone who hopes to find out about this topic. You understand so much its almost tough to argue with you (not that I personally will need to…HaHa). You definitely put a brand new spin on a subject which has been written about for years. Excellent stuff, just great.

Hello there, just became alert to your blog through Google, and found that it’s truly informative. I am gonna watch out for brussels. I?ll appreciate if you continue this in future. A lot of people will be benefited from your writing. Cheers!

obviously like your website but you have to check the spelling on several of your posts. A number of them are rife with spelling issues and I find it very bothersome to tell the truth nevertheless I’ll surely come back again.

These days of austerity along with relative anxiety about getting debt, many people balk about the idea of employing a credit card to make acquisition of merchandise or pay for a trip, preferring, instead to rely on the particular tried in addition to trusted means of making payment – raw cash. However, if you’ve got the cash there to make the purchase entirely, then, paradoxically, that is the best time for you to use the credit card for several reasons.

You need to take part in a contest for one of the greatest sites on the web. I will recommend this website!

After looking into a few of the blog posts on your web page, I truly appreciate your way of writing a blog. I added it to my bookmark site list and will be checking back in the near future. Please check out my web site as well and let me know what you think.

Great blog here! Also your site loads up fast! What host are you using? Can I get your affiliate link to your host? I wish my web site loaded up as quickly as yours lol

Youre so cool! I dont suppose Ive learn something like this before. So nice to find any person with some unique ideas on this subject. realy thanks for beginning this up. this web site is one thing that is needed on the internet, someone with just a little originality. useful job for bringing something new to the internet!

Today, I went to the beachfront with my children. I found a sea shell and gave it to my 4 year old daughter and said “You can hear the ocean if you put this to your ear.” She placed the shell to her ear and screamed. There was a hermit crab inside and it pinched her ear. She never wants to go back! LoL I know this is completely off topic but I had to tell someone!

Thanks for your posting. One other thing is the fact that individual states have their particular laws in which affect householders, which makes it very, very hard for the Congress to come up with a new set of rules concerning property foreclosure on homeowners. The problem is that a state offers own laws which may have interaction in a negative manner when it comes to foreclosure plans.

Thank you for some other informative web site. The place else may I get that type of info written in such an ideal approach? I have a mission that I am simply now operating on, and I’ve been at the glance out for such information.

I like the efforts you have put in this, regards for all the great posts.

Great web site you’ve got here.. It’s difficult to find excellent writing like yours these days. I seriously appreciate individuals like you! Take care!!

I will immediately grasp your rss feed as I can not find your email subscription hyperlink or newsletter service. Do you have any? Kindly permit me recognize in order that I may subscribe. Thanks.

Excellent post. I am experiencing a few of these issues as well..

I would like to thank you for the efforts you’ve put in penning this site. I’m hoping to view the same high-grade content by you later on as well. In truth, your creative writing abilities has encouraged me to get my own website now 😉

Of course, what a fantastic site and revealing posts, I surely will bookmark your website.Best Regards!

That is a great tip especially to those fresh to the blogosphere. Short but very precise information… Thanks for sharing this one. A must read post.

I?¦ve learn several excellent stuff here. Definitely value bookmarking for revisiting. I wonder how so much effort you set to create one of these excellent informative web site.

There may be noticeably a bundle to learn about this. I assume you made certain nice points in features also.

excellent issues altogether, you simply won a new reader. What might you recommend in regards to your post that you just made some days ago? Any sure?

I went over this web site and I think you have a lot of wonderful info , saved to fav (:.

you’ve a terrific blog here! would you like to make some invite posts on my blog?

Hello my friend! I wish to say that this post is awesome, nice written and include almost all important infos. I would like to see more posts like this.

Incredible! This blog looks just like my old one! It’s on a totally different subject but it has pretty much the same layout and design. Excellent choice of colors!

I do agree with all of the ideas you have presented in your post. They’re very convincing and will certainly work. Still, the posts are very short for newbies. Could you please extend them a little from next time? Thanks for the post.

Can I just say what a aid to seek out someone who actually knows what theyre speaking about on the internet. You definitely know how one can deliver a difficulty to mild and make it important. Extra folks have to learn this and perceive this facet of the story. I cant imagine youre no more common since you undoubtedly have the gift.

After study just a few of the blog posts in your web site now, and I really like your method of blogging. I bookmarked it to my bookmark website list and can be checking back soon. Pls check out my web site as properly and let me know what you think.

You can certainly see your skills within the paintings you write. The sector hopes for more passionate writers such as you who aren’t afraid to mention how they believe. All the time go after your heart.

I really like your blog.. very nice colors & theme. Did you make this website yourself or did you hire someone to do it for you? Plz answer back as I’m looking to create my own blog and would like to find out where u got this from. appreciate it

Yeah bookmaking this wasn’t a speculative determination great post! .

Great beat ! I wish to apprentice whilst you amend your web site, how could i subscribe for a weblog website? The account aided me a applicable deal. I were a little bit familiar of this your broadcast provided bright clear idea

I’m not sure why but this web site is loading very slow for me. Is anyone else having this problem or is it a problem on my end? I’ll check back later on and see if the problem still exists.

F*ckin? amazing things here. I?m very glad to see your article. Thanks a lot and i am looking forward to contact you. Will you please drop me a e-mail?

I?ll right away grab your rss feed as I can not find your e-mail subscription link or newsletter service. Do you’ve any? Kindly let me know so that I could subscribe. Thanks.

Great post. I used to be checking continuously this blog and I am impressed! Extremely useful info specifically the remaining phase 🙂 I maintain such info much. I used to be looking for this particular info for a very long time. Thank you and good luck.

Wow that was unusual. I just wrote an extremely long comment but after I clicked submit my comment didn’t appear. Grrrr… well I’m not writing all that over again. Anyway, just wanted to say fantastic blog!

Would you be keen on exchanging links?

This actually answered my drawback, thanks!

Hi, Neat post. There’s a problem with your web site in internet explorer, would check this? IE still is the market leader and a big portion of people will miss your wonderful writing due to this problem.

hi!,I like your writing very much! share we communicate more about your article on AOL? I need a specialist on this area to solve my problem. May be that’s you! Looking forward to see you.

Thanx for the effort, keep up the good work Great work, I am going to start a small Blog Engine course work using your site I hope you enjoy blogging with the popular BlogEngine.net.Thethoughts you express are really awesome. Hope you will right some more posts.

Hi there, You’ve done a fantastic job. I’ll definitely digg it and personally recommend to my friends. I am confident they will be benefited from this web site.

You have brought up a very great points, regards for the post.

Travel insurance is exclusive and varies relying on the

small print of your journey.

Very interesting information!Perfect just what I was looking for! “…obstacles do not exist to be surrendered to, but only to be broken.” by Adolf Hitler.

Hey! Quick question that’s entirely off topic. Do you know how to make your site mobile friendly? My web site looks weird when browsing from my iphone4. I’m trying to find a template or plugin that might be able to correct this issue. If you have any recommendations, please share. With thanks!

When you choose Selective, you choose greater than an insurance policy.

This is really interesting, You are a very skilled blogger. I’ve joined your feed and look forward to seeking more of your excellent post. Also, I have shared your web site in my social networks!

I’ve been absent for a while, but now I remember why I used to love this web site. Thanks, I will try and check back more often. How frequently you update your web site?

I’ll right away grab your rss feed as I can’t find your e-mail subscription hyperlink or newsletter service. Do you have any? Kindly permit me recognise so that I may subscribe. Thanks.

Hello, you used to write wonderful, but the last few posts have been kinda boringK I miss your tremendous writings. Past few posts are just a bit out of track! come on!

I was suggested this website by my cousin. I am not sure whether this post is written by him as nobody else know such detailed about my problem. You are wonderful! Thanks!

Good day! Would you mind if I share your blog with my zynga group? There’s a lot of folks that I think would really enjoy your content. Please let me know. Thanks

Hey there, You have done a great job. I?ll certainly digg it and personally suggest to my friends. I’m sure they’ll be benefited from this web site.

Thank you for the sensible critique. Me & my neighbor were just preparing to do some research on this. We got a grab a book from our area library but I think I learned more from this post. I am very glad to see such great info being shared freely out there.

What’s Taking place i am new to this, I stumbled upon this I have discovered It positively useful and it has helped me out loads. I am hoping to contribute & help other customers like its aided me. Great job.

My website: частное порно студентов

I’ve learned new things through your blog post. One more thing to I have discovered is that in most cases, FSBO sellers may reject you actually. Remember, they’d prefer to not use your solutions. But if anyone maintain a reliable, professional relationship, offering assistance and keeping contact for around four to five weeks, you will usually be capable of win a conversation. From there, a listing follows. Cheers

Saved as a favorite, I really like your blog!

Thanks for giving your ideas. Something is that scholars have an option between government student loan along with a private education loan where it really is easier to opt for student loan debt consolidation loan than in the federal education loan.

Regards for this terrific post, I am glad I discovered this web site on yahoo.

I gotta favorite this site it seems very beneficial handy

My website: трахают студенток

One thing I’d prefer to say is that car insurance termination is a terrifying experience so if you’re doing the best things being a driver you simply will not get one. Some individuals do get the notice that they have been officially dropped by their insurance company and several have to scramble to get added insurance from a cancellation. Affordable auto insurance rates are frequently hard to get after the cancellation. Having the main reasons pertaining to auto insurance canceling can help individuals prevent losing one of the most significant privileges readily available. Thanks for the ideas shared through your blog.

Purchase insurance can cover individual purchase

protection, warranties, guarantees, care plans and even mobile phone insurance.

Thank you ever so for you blog. Really looking forward to read more.

My website: русское любительское домашнее порно

A person essentially help to make seriously articles I would state. This is the first time I frequented your web page and thus far? I amazed with the research you made to make this particular publish incredible. Great job!

Thank you ever so for you blog. Really looking forward to read more.

My website: русскоедомашнеепорно

Good info and right to the point. I am not sure if this is really the best place to ask but do you guys have any thoughts on where to employ some professional writers? Thank you 🙂

Hi are using WordPress for your blog platform? I’m new to the blog world but I’m trying to get started and set up my own. Do you need any coding knowledge to make your own blog? Any help would be really appreciated!

Real superb information can be found on weblog. “I believe in nothing, everything is sacred. I believe in everything, nothing is sacred.” by Tom Robbins.

Great beat ! I would like to apprentice whilst you amend your site, how can i subscribe for a blog site? The account helped me a appropriate deal. I had been a little bit familiar of this your broadcast offered brilliant clear concept

What i don’t understood is in reality how you’re no longer really a lot more neatly-liked than you may be right now. You are so intelligent. You already know thus considerably on the subject of this subject, made me for my part believe it from numerous various angles. Its like women and men don’t seem to be fascinated until it’s something to accomplish with Lady gaga! Your own stuffs nice. Always maintain it up!

You really make it appear really easy along with your presentation but I to find this matter to be actually something that I feel I’d never understand. It seems too complex and extremely large for me. I am looking ahead in your next put up, I’ll attempt to get the hold of it!

Hi, Neat post. There’s an issue together with your site in web explorer, may check this… IE still is the market chief and a big component of people will leave out your fantastic writing because of this problem.

Thanks for all your efforts that you have put in this. very interesting info .

I haven?¦t checked in here for some time as I thought it was getting boring, but the last several posts are great quality so I guess I?¦ll add you back to my daily bloglist. You deserve it my friend 🙂

In this grand design of things you receive an A+ for hard work. Exactly where you actually lost me was on your facts. As people say, the devil is in the details… And it could not be more true in this article. Having said that, allow me tell you what did deliver the results. Your article (parts of it) can be pretty powerful and that is probably why I am taking the effort in order to opine. I do not make it a regular habit of doing that. Secondly, despite the fact that I can notice the jumps in logic you make, I am not certain of just how you seem to connect the details which in turn make the final result. For right now I will subscribe to your point but wish in the near future you connect your dots better.

Hello very cool web site!! Man .. Excellent .. Wonderful .. I’ll bookmark your blog and take the feeds also?KI’m satisfied to seek out numerous useful information here in the publish, we’d like develop more strategies on this regard, thanks for sharing. . . . . .

I am now not sure where you’re getting your information, however great topic. I needs to spend a while studying much more or working out more. Thank you for excellent info I used to be in search of this info for my mission.

I like the valuable information you provide on your articles. I’ll bookmark your weblog and take a look at once more right here regularly. I’m slightly certain I’ll be told lots of new stuff right right here! Good luck for the following!

I think other website proprietors should take this site as an model, very clean and fantastic user genial style and design, let alone the content. You’re an expert in this topic!

Very interesting information!Perfect just what I was searching for!

I was examining some of your blog posts on this internet site and I believe this site is really informative ! Retain putting up.

I’ll right away seize your rss as I can’t in finding your email subscription link or e-newsletter service. Do you’ve any? Please permit me know so that I could subscribe. Thanks.

Wohh precisely what I was searching for, regards for putting up.

My website: секс по русски

I don’t unremarkably comment but I gotta state regards for the post on this one : D.

Pretty! This was a really wonderful post. Thank you for your provided information.

I don?t even know how I ended up here, but I thought this post was great. I don’t know who you are but definitely you are going to a famous blogger if you are not already 😉 Cheers!

Hey very cool blog!! Man .. Excellent .. Amazing .. I will bookmark your blog and take the feeds also…I’m happy to find a lot of useful information here in the post, we need work out more techniques in this regard, thanks for sharing. . . . . .

hey there and thank you for your info ? I?ve definitely picked up something new from right here. I did however expertise some technical issues using this website, as I experienced to reload the site many times previous to I could get it to load correctly. I had been wondering if your web hosting is OK? Not that I am complaining, but sluggish loading instances times will often affect your placement in google and could damage your quality score if ads and marketing with Adwords. Anyway I am adding this RSS to my e-mail and can look out for much more of your respective intriguing content. Make sure you update this again very soon..

I was very happy to seek out this internet-site.I wanted to thanks for your time for this glorious read!! I positively having fun with every little little bit of it and I’ve you bookmarked to check out new stuff you blog post.

very nice put up, i actually love this web site, carry on it

Hello. Great job. I did not anticipate this. This is a splendid story. Thanks!

This is very interesting, You’re a very skilled blogger. I’ve joined your rss feed and look forward to seeking more of your great post. Also, I have shared your website in my social networks!

Wow, fantastic blog structure! How long have you been running a blog for? you made running a blog glance easy. The entire glance of your site is great, let alone the content material!

I haven¦t checked in here for some time because I thought it was getting boring, but the last few posts are great quality so I guess I¦ll add you back to my everyday bloglist. You deserve it my friend 🙂

A formidable share, I just given this onto a colleague who was doing a bit analysis on this. And he the truth is bought me breakfast because I discovered it for him.. smile. So let me reword that: Thnx for the deal with! However yeah Thnkx for spending the time to debate this, I feel strongly about it and love reading extra on this topic. If possible, as you turn into experience, would you thoughts updating your blog with extra details? It’s highly useful for me. Huge thumb up for this blog submit!

Very interesting info !Perfect just what I was searching for!

I like this web site so much, bookmarked.

I know this if off topic but I’m looking into starting my own blog and was wondering what all is required to get setup? I’m assuming having a blog like yours would cost a pretty penny? I’m not very web smart so I’m not 100 sure. Any suggestions or advice would be greatly appreciated. Appreciate it

Wonderful beat ! I would like to apprentice whilst you amend your site, how could i subscribe for a blog site? The account aided me a appropriate deal. I had been a little bit familiar of this your broadcast provided vivid transparent idea

so much excellent info on here, : D.

Hello my loved one! I wish to say that this article is awesome, great written and include approximately all vital infos. I would like to peer more posts like this.

Yay google is my queen assisted me to find this outstanding internet site! .

I’ve been absent for a while, but now I remember why I used to love this site. Thank you, I’ll try and check back more frequently. How frequently you update your site?

Whats up are using WordPress for your site platform? I’m new to the blog world but I’m trying to get started and set up my own. Do you need any coding knowledge to make your own blog? Any help would be greatly appreciated!

You really make it seem so easy along with your presentation however I to find this matter to be really something that I think I’d by no means understand. It seems too complicated and extremely vast for me. I am having a look forward on your subsequent post, I¦ll attempt to get the hang of it!

Somebody essentially help to make seriously articles I would state. This is the first time I frequented your website page and thus far? I surprised with the research you made to make this particular publish extraordinary. Magnificent job!

There are some interesting points in time in this article but I don?t know if I see all of them middle to heart. There is some validity but I’ll take maintain opinion till I look into it further. Good article , thanks and we wish extra! Added to FeedBurner as properly

I’ve been absent for some time, but now I remember why I used to love this web site. Thank you, I will try and check back more frequently. How frequently you update your website?

F*ckin’ amazing things here. I’m very glad to see your post. Thanks a lot and i’m looking forward to contact you. Will you please drop me a e-mail?

Those are yours alright! . We at least need to get these people stealing images to start blogging! They probably just did a image search and grabbed them. They look good though!

Hi there! Would you mind if I share your blog with my myspace group? There’s a lot of folks that I think would really enjoy your content. Please let me know. Many thanks

I do enjoy the manner in which you have presented this concern plus it does present us a lot of fodder for thought. On the other hand, because of everything that I have personally seen, I basically trust as the feed-back stack on that individuals remain on issue and don’t embark upon a soap box associated with the news of the day. Still, thank you for this outstanding piece and while I can not really agree with the idea in totality, I regard your point of view.

Hi there, just became aware of your blog through Google, and found that it’s truly informative. I am gonna watch out for brussels. I?ll be grateful if you continue this in future. Lots of people will be benefited from your writing. Cheers!

Hi, just required you to know I he added your site to my Google bookmarks due to your layout. But seriously, I believe your internet site has 1 in the freshest theme I??ve came across. It extremely helps make reading your blog significantly easier.

Hey just wanted to give you a brief heads up and let you know a few of the pictures aren’t loading properly. I’m not sure why but I think its a linking issue. I’ve tried it in two different browsers and both show the same outcome.

I enjoy what you guys are up too. This sort of clever work and exposure! Keep up the very good works guys I’ve incorporated you guys to blogroll.

Pretty! This was a really wonderful post. Thank you for your provided information.

With every little thing which seems to be building inside this particular subject matter, many of your opinions are quite refreshing. However, I beg your pardon, because I do not give credence to your entire suggestion, all be it stimulating none the less. It looks to me that your opinions are generally not completely validated and in reality you are generally yourself not fully convinced of the point. In any event I did appreciate reading through it.

Hello! I could have sworn I’ve been to this blog before but after browsing through some of the post I realized it’s new to me. Anyways, I’m definitely happy I found it and I’ll be book-marking and checking back frequently!

It is appropriate time to make some plans for the future and it’s time to be happy. I have read this post and if I could I desire to suggest you few interesting things or advice. Perhaps you could write next articles referring to this article. I desire to read more things about it!

You really make it appear really easy together with your presentation however I to find this topic to be actually something that I think I might never understand. It sort of feels too complicated and extremely huge for me. I am having a look forward in your next post, I will try to get the hold of it!

Hey very cool web site!! Man .. Beautiful .. Amazing .. I will bookmark your web site and take the feeds also?I am happy to find so many useful info here in the post, we need develop more techniques in this regard, thanks for sharing. . . . . .

Hi! I could have sworn I’ve been to this website before but after reading through some of the post I realized it’s new to me. Anyways, I’m definitely happy I found it and I’ll be bookmarking and checking back frequently!

Awsome blog! I am loving it!! Will come back again. I am taking your feeds also

Attractive section of content. I simply stumbled upon your site and in accession capital to say that I get actually enjoyed account your weblog posts. Any way I will be subscribing in your feeds and even I achievement you get right of entry to persistently rapidly.

Of course, what a splendid blog and revealing posts, I surely will bookmark your site.Have an awsome day!

My developer is trying to persuade me to move to .net from PHP. I have always disliked the idea because of the costs. But he’s tryiong none the less. I’ve been using WordPress on several websites for about a year and am anxious about switching to another platform. I have heard great things about blogengine.net. Is there a way I can import all my wordpress posts into it? Any kind of help would be really appreciated!

Please let me know if you’re looking for a article writer for your weblog. You have some really good posts and I believe I would be a good asset. If you ever want to take some of the load off, I’d really like to write some articles for your blog in exchange for a link back to mine. Please blast me an e-mail if interested. Cheers!

Thank you for sharing superb informations. Your website is so cool. I’m impressed by the details that you’ve on this website. It reveals how nicely you perceive this subject. Bookmarked this website page, will come back for extra articles. You, my friend, ROCK! I found simply the information I already searched all over the place and simply couldn’t come across. What a great site.

It’s the best time to make some plans for the future and it is time to be happy. I have read this post and if I could I desire to suggest you some interesting things or tips. Perhaps you could write next articles referring to this article. I want to read even more things about it!

I will immediately grab your rss feed as I can’t find your email subscription link or newsletter service. Do you have any? Please allow me understand in order that I may subscribe. Thanks.

Youre so cool! I dont suppose Ive read anything like this before. So good to seek out any person with some authentic ideas on this subject. realy thanks for starting this up. this web site is one thing that’s wanted on the web, somebody with a little originality. helpful job for bringing one thing new to the web!

Appreciate it for this grand post, I am glad I detected this web site on yahoo.

With havin so much content and articles do you ever run into any problems of plagorism or copyright infringement? My website has a lot of exclusive content I’ve either authored myself or outsourced but it looks like a lot of it is popping it up all over the web without my authorization. Do you know any techniques to help reduce content from being ripped off? I’d genuinely appreciate it.

I am glad to be a visitant of this stark web blog! , thanks for this rare information! .

The future of 3D printing is in new materials. I like bronzefill and it is time to test Biome3D.

Thanks for sharing