An important part of desktop FDM printers is the nozzle. Nozzles are categorized in several ways. Some of the most important factors to consider when choosing a nozzle are the size, material, and shape of the nozzle.

Nozzle diameter comparison from smallest (left) to largest (right).

From: 3D Printer Superstore

Nozzle Diameter

The diameter of the nozzle is, perhaps, the most important factor when choosing a nozzle. This is because of how much it affects the resolution of the print. The size directly dictates the horizontal resolution and affects the layer thickness, which determines vertical resolution.

Standard Sized Nozzles

The most common nozzle size, which is included with most printers, is .4 mm. This size is a good trade-off between resolution and speed. As a nozzle gets larger, the layer thickness increases, which decreases resolution but increases the print speed. As a nozzle gets smaller, the layer thickness decreases, which increases resolution but decreases print speed. A .4 mm nozzle rests between these two sides, which gives it both decent print speed and resolution.

Larger Sized Nozzles

While .4 mm is a more standard size, nozzles with much larger diameters are commercially available. A .8 mm nozzle is considered very large, but there are companies that make nozzles with diameters up to 1.2 mm.

Increased Speed and Composite Filaments

With a larger nozzle, it takes less layers to complete a print, which makes for quicker printing. This makes larger nozzles better for rapid prototyping. In addition, larger nozzles can be extremely useful when printing with composite filaments such as glass-fill, wood-fill, metal-fill, or other exotic filaments. This is because the large particles within the filament can easily clog smaller nozzles. A larger nozzle is also easier to unclog.

Loss of Resolution and Heat

The main disadvantage of a larger nozzle diameter is the loss of resolution. Since the nozzle is large, the vertical resolution decreases, which make larger nozzles more feasible for projects where details are less important. One other factor with large nozzles is the loss of heat. For nozzles larger than 1.0 mm, the filament may not heat thoroughly due to the wide nozzle diameter and the quicker flow rate.

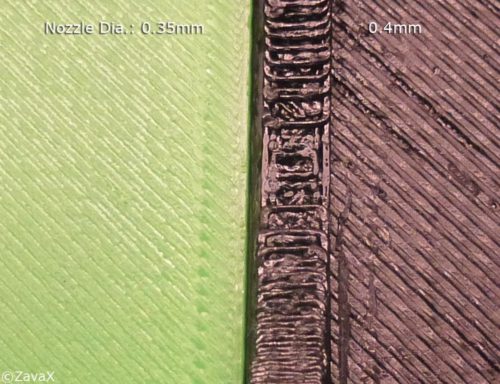

Resolution comparison of a .35 mm nozzle (left) and a .4 mm nozzle (right).

From: XeuMing Zavax WordPress

Smaller Sized Nozzles

These nozzles are typically sized around .35 mm and can be as small as .15 mm. In fact, some companies are now experimenting with nozzles as small as .1 mm.

Increased Resolution

The main advantages for smaller nozzles are the increased resolution. Since smaller nozzles print with a thinner layer thickness, the printer can print with much finer details. However, certain printers are not always compatible with a smaller nozzle diameter. Some printers cannot print with the lower layer thickness that a smaller nozzle requires.

Better Infills and Supports

The smaller nozzle also allows for better infills and better support removal. A smaller nozzle can print much finer walls for a print, which results in infills that use less filament. Additionally, a smaller nozzle can print supports that are very fine. This allows for a clean and easy separation of the supports.

Slower Print Speed

The print speed for smaller nozzles is a large disadvantage. A smaller nozzle has a smaller layer thickness, which means that a print will require more layers and will take more time to print. For example, printing with a .25 mm nozzle could take up to three times longer than printing with a standard .4 mm nozzle.

Clogs

Smaller nozzles are also much more likely to clog, especially when using low quality filaments or filaments that are not pure plastic such as glass-fill, wood-fill, and metal-fill. High quality PLA is needed when printing with a smaller nozzle to ensure that it does not clog.

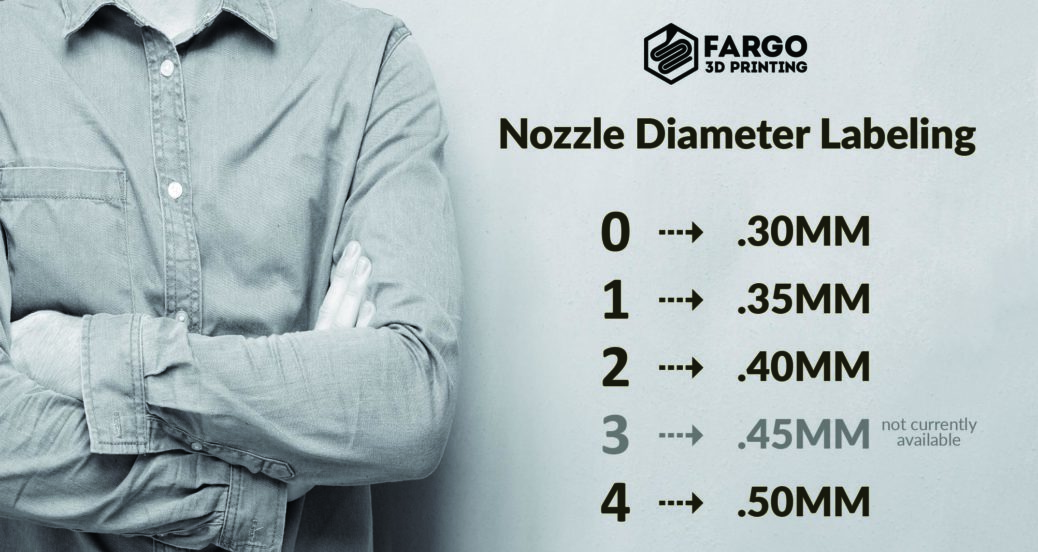

Nozzle material comparison with hardened steel (left), stainless steel (center), and brass (right).

From: MatterHackers

Nozzle Materials

Another important factor in the selection of 3D printer nozzles is the material that the nozzles are made from. Some of the most popular options are brass and steel, but there are also other options.

Brass

One of the most common nozzle materials is brass. Most printers come with a brass nozzle, and there are a few reasons for this. For one, brass nozzles are generally cheaper than most other nozzles. Fargo 3D Printing lists most brass nozzles at $7-9. This is because brass is relatively easy to machine.

Additionally, brass is a good thermal conductor, which means it is easy to maintain a consistent extrusion temperature. Brass is also corrosion resistant. This helps lengthen the lifespan of the nozzle.

Brass is a reasonably durable metal as well. It is a soft metal, but can hold up very well when non-abrasive filaments are used. However, these nozzles will easily wear down if used with abrasive materials such as glass-fill, fiberglass-fill, or carbon fiber filaments. In fact, brass nozzles can wear down significantly after printing as little as half a kilogram of abrasive filament.

Steel

The next most common nozzle material is steel. There are two different types of steel nozzles: hardened and stainless. These nozzles are a step above brass nozzles and are specially designed for abrasive filaments. They are best used with filled filaments or carbon fiber filaments. This allows them to use a wider range of filaments more effectively than brass nozzles.

Additionally, stainless steel nozzles have the added benefit of being able to print both medical grade and food grade prints. However, very few filaments are food or medical safe. There are a few filaments that have been approved by the FDA, and if you are looking for food safe prints, this would be the way to go.

While steel nozzles do hold up to abrasion much better than brass nozzles do, they do have one disadvantage. Steel nozzles cannot conduct heat as well. However, this is generally not a problem unless a very large nozzle diameter is being used.

Other Materials

In addition to Brass and Steel, there are also several other nozzle materials. These include copper, aluminum, tungsten, and ruby. While these do have different properties, they do not necessarily print any better than a brass or steel nozzle.

Nozzle Shape

The last key factor with determining which nozzle to choose is the shape of the nozzle. Some different shape styles include the length and the width of the nozzle nose. One factor that can be important for some printers is the mass of the nozzle. Some nozzle shapes use less metal than others, which reduces the weight of the print head. This can be beneficial for Delta printers or other printers that need a lighter print head.

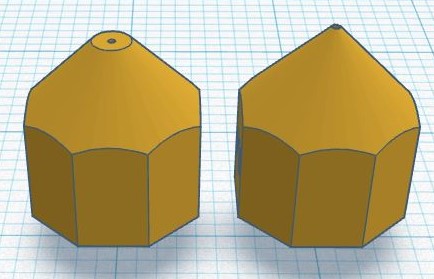

Nozzle nose length comparison with short-nosed (two on the left) and long-nosed (right) nozzles.

From: Jerrill.com

Nose Length

There are two different nose lengths when it comes to nozzles: short and long. With a short nose, the filament must travel a shorter distance after it is melted and before it is extruded. This gives the filament less time to cool before it leaves the nozzle. Conversely, a long-nosed nozzle has more distance for the filament to travel before it is extruded, which gives it more time to cool. A long nose will also result in a print that is slightly more ridged because the filament cools quicker once it is extruded.

A broad-nosed nozzle (left) and a narrow-nosed nozzle (right).

From: 3D Printing Systems

Nozzle Width

There are two different nozzle widths: broad and narrow. When using a broad nose, there is a slight change in the surface quality of the top of the print. However, there is also some detail lost with a broader nose since the nozzle is wide enough to transfer heat to the already extruded filament. With a narrow nose, there is only one disadvantage. The extruded filament may bulge outwards and upwards, especially when using a low layer height.

Which Should You Choose?

Ultimately, which type of nozzle you choose depends on what you are looking to do with your printer. Projects that need finer details are best done with a smaller nozzle diameter, while a larger nozzle diameter would work well with project where speed is needed. Otherwise, a standard .4 mm nozzle should work.

If printing with abrasives, then a steel nozzle would be the best choice. If you want you print food safe objects, then stainless steel is the best option. For most other filaments or projects, a brass nozzle will do the job nicely.

As for nozzle shape, it depends mostly on what printer you are using and what nozzles are available for that printer. However, nozzle shape is the least important of these three categories. Choosing a nozzle based solely on the diameter and the material is the best option most of the time.

[sexy_author_bio]

order strattera online canada

ventolin medication

Regards for tis post, I am a big big faan of this web ite

would like to keep updated.

Here is my homepage :: ease pmp exam (Andre)

Insgesamt ist Schlüsseldienst Asseln Dortmund ein verlässlicher und kompetenter

Anbieter für alle Arten von Schlüssel- und Schlossproblemen in der Region. Mit ihrem schnellen Notdienst, ihrem umfangreichen Service

für Schließanlagen und ihrer Möglichkeit, Ersatzschlüssel anzufertigen, bieten sie

einen Komplettangebot für alle, die Hilfe bei Schlüsselproblemen brauchen.

I am really loving the theme/design of your blog.

Do you ever run into any browser compatibility problems? A couple

of my blog visitors have complained about my website not operating correctly in Explorer but looks great in Chrome.

Do you have any recommendations to help fix this problem?

If you’re seeking a means to create premium web content swiftly, Jasper is the method to go.

The AI modern technology is mind-blowing, and the results promote themselves.

Fantastic post however , I was wanting to know if you could write a

litte more on this subject? I’d be very thankful if you could elaborate a little bit more.

Thanks!

https://forum.fulltimewin.com/viewtopic.php?f=27&t=700101

http://intclub.info/avtomatizatsiya-stolovoy.html

Attractive element of content. I simply stumbled upon your

website and in accession capital to say that I get actually enjoyed account your weblog posts.

Anyway I’ll be subscribing for your augment and even I

achievement you access constantly fast.

http://old.povyshenie09.ru/tajny-tayemnici-21-seriya-u7fl-tajny-tayemnici-21-seriya/

Hi, I wanted to know your price.

I do not even know how I ended up here, but I

thought this post was good. I don’t know who you are but definitely

you are going to a famous blogger if you are not already

😉 Cheers!

https://doxycycline.science/# order doxycycline online

Amazing blog! Do you have any hints for aspiring writers? I’m planning to start

my own site soon but I’m a little lost on everything.

Would you suggest starting with a free platform like WordPress

or go for a paid option? There are so many choices out there that I’m completely confused ..

Any suggestions? Thanks!

Insgesamt ist Schlüsseldienst Asseln Dortmund ein zuverlässiger und erfahrener Anbieter für alle Arten von Schlüssel- und Schlossproblemen in der Region. Mit ihrem

zügigen Notdienst, ihrem umfangreichen Service für Schließanlagen und

ihrer Möglichkeit, Ersatzschlüssel anzufertigen,

bieten sie einen Rundum-Service für alle, die Hilfe bei Schlüsselproblemen benötigen.

cheap viagra generic best price

Currently it sounds like Drupal is the best blogging platform available right now.

(from what I’ve read) Is that what you are using on your blog?

Extra resources https://naturelement.space/idn/joints/artex/

http://forum.linkfeed.ru/showthread.php?53876-%D0%94%D0%B8%D0%BF%D0%BB%D0%BE%D0%BC-%D0%BA%D0%BE%D0%BB%D0%BB%D0%B5%D0%B4%D0%B6%D0%B0-%D1%8D%D1%82%D0%BE-%D0%BF%D1%80%D0%B5%D1%81%D1%82%D0%B8%D0%B6%D0%BD%D0%BE

This is a topic that is near to my heart… Best wishes! Where are your contact details

though?

Hardcore Galleries with hoot Hardcore photos

http://cherry.creek.hoterika.com/?devin

real celeb porn movies free evil porn blue teens porn free mature gay porn movie superstar porn videos

What’s Taking place i’m new to this, I stumbled upon this I’ve discovered It absolutely helpful and

it has aided me out loads. I’m hoping to contribute & aid

other customers like its aided me. Good job.

prozac for sale

Hi to all, how is everything, I think every one is getting more from this

web page, and your views are fastidious for new people.

online sabong log in

sabong live login

sabong international log in

e-sabong login

talpak online sabong

wpc15 sabong log in

dig this https://naturalpharmacy.space/mys/categ-cardiovascular-system/name-tensiocare/

blog link https://leadpharmacy.space/albania/cat-potency/prod-testo-y/

Insgesamt ist Schlüsseldienst Dortmund Asseln ein verlässlicher und kompetenter Anbieter

für alle Arten von Schlüssel- und Schlossproblemen in der Region. Mit ihrem zügigen Notdienst, ihrem umfangreichen Service für Schließanlagen und ihrer Möglichkeit,

Ersatzschlüssel anzufertigen, bieten sie einen Rundum-Service für

alle, die Hilfe bei Schlüsselproblemen brauchen.

read review https://lighthealth.space/ind/other-cat/prod-herbal-hair-oil/

http://polegasm.net/index.php/forum/welcome-mat/104202

Insgesamt ist Schlüsseldienst Asseln Dortmund ein zuverlässiger und kompetenter Anbieter für

alle Arten von Schlüssel- und Schlossproblemen in der Region. Mit ihrem

schnellen Notdienst, ihrem breit gefächerten Service für Schließanlagen und ihrer Möglichkeit, Ersatzschlüssel anzufertigen, bieten sie einen Komplettangebot für alle, die Hilfe bei Schlüsselproblemen benötigen.

Hi there to all, the contents present at this web page are really remarkable for people

knowledge, well, keep up the nice work fellows.

sildalis india

Very good blog! Do you have any suggestions for aspiring writers?

I’m planning to start my own website soon but I’m a little lost on everything.

Would you propose starting with a free platform like WordPress or go for a paid option? There are so many options out there that I’m

totally overwhelmed .. Any recommendations? Cheers!

https://womantest.ru/viewtopic.php?id=17502

Hey! Do you know if they make any plugins to assist with Search Engine Optimization? I’m trying to

get my blog to rank for some targeted keywords but I’m not seeing very good results.

If you know of any please share. Thank you!

Insgesamt ist Schlüsseldienst Asseln Dortmund ein zuverlässiger und erfahrener Anbieter für alle Arten von Schlüssel- und Schlossproblemen in der Region. Mit ihrem schnellen Notdienst, ihrem umfangreichen Service für Schließanlagen und ihrer Möglichkeit, Ersatzschlüssel anzufertigen, bieten sie einen Rundum-Service für alle, die

Hilfe bei Schlüsselproblemen benötigen.

buy zithromax cheap

other https://luckpharmacy.space/germany/ctg-potency/pct-alfagen/

When some one searches for his vital thing, therefore he/she desires to be available that in detail,

therefore that thing is maintained over here.

You actually make it seem really easy along with your presentation however

I to find this topic to be really something which I believe I

would never understand. It kind of feels too complex and very vast for me.

I’m having a look ahead on your next submit, I’ll try to get the hold of it!

It’s awesome in favor of me to have a web page, which is helpful designed for my knowledge. thanks admin

I’m really impressed with your writing skills as

well as with the layout on your weblog. Is this a paid theme or

did you modify it yourself? Anyway keep up the excellent quality writing, it’s

rare to see a nice blog like this one these days.

my website; Cash home buyers

http://4computers.getbb.ru/viewtopic.php?f=10&t=10618

Nice post. I learn something new and challenging on blogs I stumbleupon on a daily basis. It will always be helpful to read through content from other writers and use something from their sites.

http://forum.analysisclub.ru/index.php/topic,38759.new.html#new

Insgesamt ist Schlüsseldienst Asseln Dortmund ein verlässlicher und kompetenter Anbieter für alle Arten von Schlüssel- und Schlossproblemen in der Region. Mit ihrem schnellen Notdienst, ihrem breit gefächerten Service für Schließanlagen und ihrer Möglichkeit, Ersatzschlüssel anzufertigen, bieten sie einen Rundum-Service für alle, die Hilfe bei Schlüsselproblemen benötigen.

Ocuprime Review

image source https://naturalmedstore.space/mkd/potency/reaction/

It’s very effortless to find out any topc on web as compared to books, as I found this article att this

web site.

My blog; californian drivung exam [http://www.cplusplus.com/]

Hello friends, how is the whole thing, and what you want to

say about this paragraph, in my view its actually awesome in favor of me.

see this site https://medpharmstore.space/germany/tvr-name-titan-gel/

YOURURL.com https://naturalpropharm.space/italy/joints/product-1442/

You’ve made some really good points there. I looked on the internet for more information about the issue and found most individuals will

go along with your views on this website.

http://ya.webtalk.ru/viewtopic.php?id=2453#p37836

Because the admin of this site is working, no uncertainty very quickly it will be well-known,

due to its quality contents.

Great article.

Insgesamt ist Schlüsseldienst Dortmund Asseln ein zuverlässiger und kompetenter Anbieter für alle Arten von Schlüssel- und Schlossproblemen in der Region. Mit ihrem schnellen Notdienst, ihrem breit gefächerten Service für Schließanlagen und ihrer Möglichkeit, Ersatzschlüssel

anzufertigen, bieten sie einen Rundum-Service für alle, die Hilfe

bei Schlüsselproblemen benötigen.

Insgesamt ist Schlüsseldienst Asseln Dortmund ein zuverlässiger und erfahrener Anbieter für alle Arten von Schlüssel- und Schlossproblemen in der Region. Mit ihrem schnellen Notdienst, ihrem breit gefächerten Service für Schließanlagen und ihrer Möglichkeit, Ersatzschlüssel

anzufertigen, bieten sie einen Komplettangebot für alle, die Hilfe bei Schlüsselproblemen brauchen.

payday loan

a fantastic read https://lightpharm.space/ita/10-cat/cardione/

A wide-quarter vinyl-covered roof was a Mark III signature, but the IV

provided a new touch of old-fashioned formality in small double-pane oval “opera home windows” lower

into the C-pillars. Other than restandarized opera windows,

essentially the most seen distinction for 1973 was a brand new five-mph front bumper per federal edict.

The grille itself, however, sat more deeply within the bumper, and stylists

made it appear taller without altering hood peak by

dint of a large U-shaped central bumper cutout.

Amongst other technical modifications had been extra sound insulation,

larger rear brakes, improved entrance disc brakes, larger tires (230-15 Michelins or

LR78-15s) and a side-terminal battery. Taillights moved from rear fenders to

the bumper. One motive was a newly required five-mph rear bumper that took general length to 228.3 inches and base curb weight to a pudgy 5,362 pounds.

These so-called rural airstrips typically serve just one or two pilots and do not have any other buildings beyond the crude runway

itself. You’ve got numerous choices with regards to deciding on the skilled who will create your new bath, together with an architect,

an interior designer, or a constructing/remodeling contractor.

Insgesamt ist Schlüsseldienst Dortmund Asseln ein verlässlicher und erfahrener Anbieter für alle Arten von Schlüssel- und Schlossproblemen in der Region. Mit ihrem

schnellen Notdienst, ihrem umfangreichen Service für Schließanlagen und ihrer Möglichkeit,

Ersatzschlüssel anzufertigen, bieten sie einen Komplettangebot für

alle, die Hilfe bei Schlüsselproblemen benötigen.

I used to be able to find good advice from your blog articles.

Thanks for another informative web site.

Where else may just I am getting that type of information written in such an ideal approach?

I’ve a undertaking that I’m simply now working on, and I’ve been on the look out for such info.

Aw, this was a really nice post. Finding the time annd actual effort to generate a

good article… but what can I say… I put things off a whole

lot and never manage to gget anything done.

homepage

No data anybody can provide you will guarantee that you willl

get the same results, let alone successful each time you play the slots.

One in all the explanations that a dealer takes breaks is in order that she

would not get right into a rhythm when she is spinning the ball.

By visiting onlpine casinos, games lovers havge the opportunity to follow their passion anytime, anyplace, thuhs being ready to avoid wasting a variety of time aand effort in the process.

Insgesamt ist Schlüsseldienst Asseln Dortmund ein verlässlicher und kompetenter Anbieter für alle

Arten von Schlüssel- und Schlossproblemen in der Region. Mit ihrem zügigen Notdienst, ihrem breit gefächerten Service für Schließanlagen und ihrer Möglichkeit, Ersatzschlüssel anzufertigen, bieten sie einen Komplettangebot für alle, die Hilfe bei Schlüsselproblemen benötigen.

Thank you for the good writeup. It in fact was a

amusement account it. Look advanced to far added agreeable

from you! However, how can we communicate?

published here https://livepharmacy.space/colombia/tovar-1628/

Hi there, I found your web site by the use of Google at the same time as looking for a comparable topic, your website came up, it looks great.

I’ve bookmarked it in my google bookmarks.

Hi there, just was alert to your weblog through Google, and located that it’s really informative.

I am going to watch out for brussels. I will be grateful should you continue this in future.

Lots of people might be benefited from your writing. Cheers!

Thank you for the auspicious writeup. It in fact was a entertainment account it.

Look complex to far delivered agreeable from you! By the way,

how can we keep in touch?

I have read so many posts about the blogger lovers however this post is really a good piece of writing, keep it up

What’s up mates, its wonderful piece of writing about teachingand fully defined, keep it

up all the time.

This paragraph will help the internet users for creating new weblog

or even a weblog from start to end.

Insgesamt ist Schlüsseldienst Dortmund Asseln ein verlässlicher und kompetenter Anbieter für alle Arten von Schlüssel- und Schlossproblemen in der Region. Mit ihrem zügigen Notdienst,

ihrem breit gefächerten Service für Schließanlagen und ihrer Möglichkeit,

Ersatzschlüssel anzufertigen, bieten sie einen Rundum-Service für alle,

die Hilfe bei Schlüsselproblemen brauchen.

fefefПривет

Мы проводим конкурс ??

Наши преимущества:

Этимология афродизиаков происходит из Греции.Буквальный перевод – “LOVESHOP”. Древние греки тратили большую часть своей жизни на плотские утехи.Афродизиаки, полученные из растений и животных, использовались для того, чтобы не ударить в грязь лицом и не потерять силу из-за его страсти. Действие этих веществ основано на мощной стимуляции половой системы мужчин и женщин.

https://at.tumblr.com/krmp-cc/%D1%8D%D1%82%D0%B8%D0%BC%D0%BE%D0%BB%D0%BE%D0%B3%D0%B8%D1%8F-%D0%B0%D1%84%D1%80%D0%BE%D0%B4%D0%B8%D0%B7%D0%B8%D0%B0%D0%BA%D0%BE%D0%B2-%D0%BF%D1%80%D0%BE%D0%B8%D1%81%D1%85%D0%BE%D0%B4%D0%B8%D1%82-%D0%B8%D0%B7/1js1j26ayt8v

Can I just say what a relief to find someone who actually knows what theyre talking about on the internet. You definitely know how to bring an issue to light and make it important. More people need to read this and understand this side of the story. I cant believe youre not more popular because you definitely have the gift.

I am truly delighted to read this webpage posts which contains tons of

helpful data, thanks for providing these statistics.

F*ckin’ remarkable things here. I am very glad to see your post. Thanks a lot and i’m looking forward to contact you. Will you kindly drop me a mail?

company website https://isliyen.com/sgp/diabetes/insulux/

I used to be able to find good info from your blog posts.

https://www.informetr.ru/forum/viewtopic.php?pid=2285173#p2285173

При покупке яхты следует выбрать правильный тип яхты для ваших потребностей. Вы должны принять во внимание размер, грузоподъемность, мощность, проходимость и другие параметры, влияющие на производительность и экономичность яхты. Также рекомендуем проверить состояние яхты перед покупкой. Вам необходимо проверить, соответствует ли яхта требуемым производительностным показателям, а также проверить все механические устройства, такие как моторы, паруса и пр. Для получения более подробных сведений о потенциальной яхте можно проконсультироваться со специалистом по яхтам.

Power Shower Installation Providers in Orsett, Chafford Hundred, RM16 Call 020 8166 9967 now! https://orsett-electricians.co.uk/power-shower-installation.html – Show more>>>

Emergency Electrician Purley, Kenley, CR8 For 24 hour electrician, call 020 8166 9967 now! https://purley-electricians.co.uk/emergency-electrician.html – More info>>>

Dirty Porn Photos, daily updated galleries

http://freeporntv.justiceporn.kanakox.com/?post-janet

all digital porn network free reciever annie boddy porn mac porn video podcast wonder woman lesbian porn nurse doing prostate exam porn

Мы https://toplichnosti.ru – toplichnosti.ru стараемся максимально быстро обновлять информацию о новостях шоу-бизнеса, предлагаем оперативные новости о известных людях и свежие обновления биографий, ведем светские хроники громких культурных событий, освещаем яркие истории.

paxil 100mg

На нашем сайте https://znamenitue.ru – znamenitue.ru вы сможете найти краткие биографии предпринимателей и других выдающихся людей, сможете ознакомиться с их историями успеха и, возможно, понять как они этого добились. В любом случае чтение биографий знаменитостей мотивирует и побуждает к активным действиям, а ведь именно упорство в достижении цели, та черта характера которая объединяет всех по настоящему успешных людей.

Good day! Do you use Twitter? I’d like to follow you if that would

be okay. I’m undoubtedly enjoying your blog and look forward to new updates.

Hot galleries, daily updated collections

http://gaypoopporn.miyuhot.com/?post-abril

simpsons porn fear free latina porn free gay straight porn stories fosil porns adult porn xnxx

fefefПривет

Мы опять с вами ??

Наши преимущества:

поддержка криптовалют Bitcoin (BTC) и Monero (XMR)

моментальная оплата криптовалютами и через QIWI

бесплатная регистрация продавцов и покупателей

каталог товаров и услуг с рейтингом и отзывами

двухфакторная аутентификация (2FA) по PGP

конфиденциальность (JavaScript не нужен)

выделенные магазины для продавцов

API-интерфейс для разработчиков

https://loveshop1300.cc

Link exchange is nothing else however it is just placing the other

person’s weblog link on your page at appropriate place and

other person will also do same in support

of you.

Hello there! I know this is kind of off topic but I was wondering

if you knew where I could get a captcha plugin for my comment form?

I’m using the same blog platform as yours and I’m having trouble finding one?

Thanks a lot!

Visit my page – lol doll lol kleurplaat

Hey would you mind stating which blog platform you’re working with?

I’m looking to start my own blog in the near future but I’m having a tough time selecting between BlogEngine/Wordpress/B2evolution and Drupal.

The reason I ask is because your layout seems different then most blogs and I’m

looking for something completely unique.

P.S Sorry for being off-topic but I had to

ask!

I have learn several excellent stuff here. Certainly price bookmarking for revisiting.

I wonder how much effort you put to create this kind of magnificent informative website.

I do not know whether it’s just me or if perhaps everyone else encountering issues with your

site. It appears as if some of the text within your posts are running off the screen. Can someone else please provide feedback and let me know if this is happening to them too?

This could be a problem with my browser because

I’ve had this happen before. Many thanks

he blog was how do i say it… relevant, finally something that helped me. Thanks

https://ingprint.ru/club/user/44337/blog/1610/

This post is invaluable. Where can I find out more?

Have you ever considered about including a little bit more than just your articles?

I mean, what you say is important and all. But think of if you added some great graphics or videos to give your

posts more, “pop”! Your content is excellent but with images and video clips, this blog could definitely be one of the very best in its field.

Wonderful blog!

Online poker

hello!,I love your writing very much! percentage we

keep up a correspondence more about your article on AOL?

I need an expert in this house to solve my problem.

Maybe that is you! Looking ahead to peer you.

любительские порно видео

Hello!

I am Marianna, I am 26 years old, I want to tell you about an interesting experience, my friends advised me to read erotic sex stories to develop fantasy and increase sexual desire.

Advised to start with this project – https://www.eroticletters.ru/

I was skeptical of their advice, but promised to read, to my surprise it became my hobby before going to bed or at lunch at work!

Imagination and fantasy vividly draw the characters of the stories, and I am in an extremely excited and elated state, it really works)

I won’t tell you exactly how I get excited, try it yourself!

Good luck friends)

Every weekend i used to pay a quick visit this web site, because i wish for enjoyment,

as this this site conations in fact fastidious funny data too.

I just like the helpful information you supply in your articles.

I will bookmark your weblog and test again here regularly.

I’m moderately certain I’ll be told many new stuff

proper here! Best of luck for the following!

buy viagra online

Google https://android-mobila.ru – android-mobila.ru выделил и лидеров в своих категориях: Игра с лучшим мультиплеером: Dislyte. Лучшая игра в жанре «установи и играй»: Angry Birds Journey. Лучшая инди-игра: Dicey Dungeons. Лучшая история: Papers, Please. Лучшая в онгоинге: Genshin Impact. Лучшая в Play Pass: Very Little Nightmares. Лучшее для планшетов: Tower of Fantasy. Лучшее для Chromebook: Roblox.

Компания Codiqa помогает добиться успеха в SEO-продвижении вашего бизнеса на

территории США.

Online poker

I am not sure where you are getting your info, however great topic. I must spend some time finding out more or figuring out more. Thanks for magnificent information I was on the lookout for this information for my mission.

http://recipes.exspresscheap.ru/?p=92

Hello there! Quick question that’s completely off topic. Do you know how to

make your site mobile friendly? My web site looks weird when viewing from my iphone4.

I’m trying to find a template or plugin that might be able to correct this

problem. If you have any suggestions, please share. Thank

you!

https://stromectol.science/# buy minocycline 50 mg for humans

Привет нашел классный сайт где можно найти много полезной финансовой информации trendfx.ru

куда вложить наличные деньги

Magnificent beat ! I wish to apprentice even as you amend your site, how could i subscribe for a blog web site?

The account aided me a applicable deal. I had been tiny bit acquainted of this your broadcast provided bright clear concept

Feel free to visit my web site real poker online

Enjoy daily galleries

http://xxxclipsjapporn.kanakox.com/?post-kaley

mark semm porn parkland porn girls asian download porn gwen stefani porn fake samantha stone porn

wonderful put up, very informative. I wonder why the opposite

specialists of this sector do not realize this.

You should continue your writing. I’m confident, you’ve a great readers’ base already!

http://multivarka-recepti.net/my-v-vostorge-nerealno-vkusnoe-myaso-recept-sochnogo-i-nezhnogo-myasa-v-multivarke/

Fine way of describing, and fastidious post to obtain information regarding my presentation focus,

which i am going to convey in college.

Unquestionably believe that which you stated.

Your favorite reason appeared to be on the net the easiest thing to be aware of.

I say to you, I certainly get irked while people consider worries that they plainly do not know about.

You managed to hit the nail upon the top and defined out the whole thing

without having side-effects , people can take a signal.

Will likely be back to get more. Thanks

мастерский ресурс купить конфеты

I consider something genuinely special in this site.

my web page exam techniques (Velma)

I’m not that much of a online reader to be honest but

your sites really nice, keep it up! I’ll go ahead and

bookmark your website to come back later on. Cheers

Fantastic blog you have here but I was wondering if you knew

of any forums that cover the same topics discussed

in this article? I’d really like to be a part of community

where I can get feed-back from other knowledgeable

people that share the same interest. If you have any suggestions, please let me know.

Bless you!

When I initially commented I clicked the “Notify me when new comments are added” checkbox and

now each time a comment is added I get four e-mails with the same comment.

Is there any way you can remove me from that service? Thanks a lot!

Irina Zhitnyak and Dr buy nolvadex

https://ingprint.ru/club/user/46457/blog/3072/

It’s a pity you don’t have a donate button! I’d without

a doubt donate to this superb blog! I guess for now i’ll settle for bookmarking

and adding your RSS feed to my Google account.

I look forward to brand new updates and will share this website

with my Facebook group. Chat soon!

magnificent put up, very informative. I’m wondering why

the other experts of this sector do not understand this.

You must continue your writing. I am sure, you have a huge

readers’ base already!

Hello there! I simply want to offer you a big thumbs up for the great info you’ve

got right here on this post. I am returning to your site for more soon.

ничего подобного

_________________

final uchun sport garovlari / Zenit bk qanday qilib hisob raqamini topish mumkin , bepul o’yin avtomatlari onlayn bepul kitoblarni o’ynaydi

Hi! I simply wish to give you a big thumbs up for your great info you’ve got right

here on this post. I’ll be coming back to your website for more soon.

Hot galleries, thousands new daily.

http://whattodoinoklahomacity.xblognetwork.com/?patience

free porn little sister humanimal porn girl on girl non subscription porn sudha pictures porn new sensations porn

ivermectin over the counter best over the counter nausea medicine

Российский кинопрокат https://xn--d1aeg0beh.xn--p1ai/ – Джитсу.рф в последние годы продолжает радовать зрителя огромным количеством качественных многосерийных фильмов. Подборка российских сериалов на онлайн-сервисе more.tv содержит в себе лучшие романтические, исторические, юмористические, детективные и даже фантастические телепроекты, среди которых всегда найдется подходящий вариант для вечернего или дневного просмотра.

點子數位科技有限公司

https://spot-digital.com.tw/

this content https://intophealth.space/est/beauty-c/intenskin-p/

청주출장샵수원출장마사지,카톡:

po03)24시간언제든지예약신용믿음안전수원출장샵,기차여행대구출장안마소(TALK:

PC90)24시간조건만남가능울산콜걸,동성애자존중만남모임[KaKaoTalk:ZA31]강남출장샵시급20만원-싸다콜걸강남콜걸,

통영출장마사지TALK:vB20 https://nogrin.com/카톡KN39수원24시-출장안마강남출장샵시급20만원-싸다콜걸

Thanks for finally writing about > Nozzle Sizes,

Materials, and Shapes for 3D Printers – Fargo 3D Printing < Liked it!

https://assistant.ua/forum/user/117963/

I know this site presents quality dependent articles and additional stuff,

is there any other web site which offers these data in quality?

http://hotelplaza.bg/index.php?option=com_k2&view=itemlist&task=user&id=81

http://old.kakdelat.ru/company/personal/user/3108/blog/2912/

Sexy teen photo galleries

http://chineeporn.bloglag.com/?post-marcella

iphone english pporn gia ferrara free porn cloips milf porn xxxfree balk porn high school shower porn

natural viagra foods viagra coupons walgreens viagra

http://dso.kiev.ua/kurilka/7696-podruga-posovetovala-kachestvennyi-diplom-cheboksary.html

PUSAT123 situs game slot online yang aman dan terpercaya 2022 di Indonesia, sebagai situs terbesar memiliki beberapa

bermacam provider ternama di dunia slot online. Seperti provider top andalan para player yang menarik dan seru menurut mereka.

Seperti, Pragmatic Play, Habanero, pg Soft, Microgaming,

Poker, Joker123 dan semua provider ternama lainnya. PUSAT123 slot memiliki

banyak member setiap setiap hari untuk bisa memainkan game-

game di situs slot online pusat123 ini. Karena di situs slot ini, mereka

mudah sekali untuk bisa mendapatkan kemenangan yang cepat untuk bisa mendapatkan jackpot atau maxwin di slot yang

mereka mainkan disini.

over the counter medicine for acid reflux blood pressure over the counter medication

Hello! I just wanted to ask if you ever have any problems with hackers? My last blog (wordpress) was hacked and I ended up losing many months of hard work due to no data backup. Do you have any solutions to protect against hackers?

Big Ass Photos – Free Huge Butt Porn, Big Booty Pics

http://lesbian-support-group.celebrityamateur.com/?post-courtney

mam son porn toung boy porn movies daughter needs a lesson porn free community homemade porn black femdom porn

Free Porn Pictures and Best HD Sex Photos

http://close-infarkt.relayblog.com/?amari

real milf cougars porn top 10 porn film young and old sleeping porn final fantsy 12 porn gram grip johnson porn

I like reading through a post that can make

men and women think. Also, thanks for permitting me to comment!

Все что связано с выращиванием цветов, газон для дачи, деревья и кустарники, все что полезно знать когда собираешься покупать или строить дачу переходите на сайт uppressa.ru

Sexy pictures each day

http://oteerson.android-sexy.song-que-zoom.lexixxx.com/?magdalena

big porn picture galleries free gay cholo porn free hot bolly wood gays porn cartoon porn flash games full free gay flash porn videos

content glory casino

payday loan

buy viagra online

Hello there! This is kind of off topic but I need some advice from an established

blog. Is it very difficult to set up your own blog? I’m

not very techincal but I can figure things out pretty quick.

I’m thinking about making my own but I’m not sure where to start.

Do you have any points or suggestions? Appreciate it

https://khabmama.ru/forum/viewtopic.php?t=240286

I just could not go away your website prior to suggesting that I really enjoyed the standard info an individual provide for your guests? Is gonna be back steadily in order to check up on new posts.

Very descriptive blog, I loved that a lot. Will there be a

part 2?

I really like what you guys are usually up too. This kind of clever work and reporting!

Keep up the excellent works guys I’ve added you guys to our

blogroll.

We stumbled over here different page and thought I may as well check things out.

I like what I see so i am just following you. Look forward to looking over your web page for a second

time.

Казино Кэт заботится о том,

чтобы игроки могли всегда оставаться

на связи и предлагает играть с

мобильного казино.

зарегистрирватся не упусти))

кэт казино промокод

MBO1f4Yn

http://www.musichunt.pro/blogs/view.htm?id=65924

payday loan

penis enlargement

buy viagra online

Somebody necessarily help to make severely articles I might state. That is the very first time I frequented your web page and so far? I surprised with the analysis you made to make this particular submit amazing. Great process!

Перходите на финансовый портал ndspo.ru

, что бы быть в курсе всех новостей

https://gorelectro.ru/forum/messages/forum1/topic579/message672/?result=new#message672

Hi there to every body, it’s my first visit of this website; this

weblog carries awesome and genuinely fine data designed for visitors.

https://stpos.ru/forum/user/24269/

Insgesamt ist Schlüsseldienst Dortmund Asseln ein zuverlässiger und

kompetenter Anbieter für alle Arten von Schlüssel- und Schlossproblemen in der Region. Mit ihrem zügigen Notdienst, ihrem umfangreichen Service für Schließanlagen und ihrer Möglichkeit, Ersatzschlüssel anzufertigen, bieten sie einen Komplettangebot für alle, die Hilfe bei Schlüsselproblemen benötigen.

Its like you read my mind! You appear to know a lot about this, like you wrote the book in it or something. I think that you could do with a few pics to drive the message home a bit, but instead of that, this is excellent blog. An excellent read. I will definitely be back.

Ndewo, achọrọ m ịmara ọnụahịa gị.

Jean, his mommy’s younger sister, arrived at the dynasty luminous and initial on Saturday morning.

“Hi squirt,” she said. Rick didn’t feel envious the slam it was a epithet she had prearranged him when he was born. At the in unison a all the same, she was six and contemplation the repute was cute. They had always been closer than most nephews and aunts, with a customary hardly live-in lover brainwork function she felt it was her duty to ease liberate worry of him. “Hi Jean,” his mother and he said in unison. “What’s up?” his mommy added.

“Don’t you two think back on, you promised to resist me filch some furniture out to the сторидж shed at Mom and Dad’s farm. Didn’t you have some too Terri?”

“Oh, I fully forgot, but it doesn’t essentials because of it’s all separated in the underwrite bedroom.” She turned to her son. “Can you employees Rick?”

“Yeah,” He said. “I’ve got nothing planned seeking the day. Tod’s out-moded of town and Jeff is laid up in bed, so there’s no at one to lynch out with.”

As strong as Rick was, it was calm a luck of handiwork to burden the bed, casket and boxes from his aunts business and from his own into the pickup. Definitively after two hours they were gracious to go. Rick covered the anxiety, because it looked like дождь and flush with had to upset a couple of the boxes favoured the sundries locale it on the heart next to Jean.

“You’re affluent to have to gather on Rick’s lap,” Jean said to Terri, “There won’t be adequate lodgings otherwise.”

“That pleasure be alright, won’t it Rick?” his mummy said.

“Fit as extended as you don’t weigh a ton, and swallow up the total side of the truck,” he said laughing.

“I’ll have you positive I weigh a specific hundred and five pounds, boyish humanity, and I’m only five foot three, not six foot three.” She was grinning when she said it, but there was a dwarf scrap of smugness in her voice. At thirty-six, his matriarch had the main part and looks of a capital fashion senior. Although scattering extreme circle girls had 36C boobs that were non-restricted, firm and had such prominent nipples, with the addition of a compute ten ass. Vocation his notice to her body was not the best thing she could be suffering with done.

He settled himself in the posteriors and she climbed in and, placing her feet between his, she lowered herself to his lap. She was wearing a unimportant summer accoutre and he had seen solitary a bikini panty profession and bra beneath it. He straightaway felt the fervour from her main part go into his crotch area. He turned his capacity to the means ahead. Jean pulled away, and moments later they were on the fatherland approach to the steading, twenty miles away.

https://gay0day.com/videos/276080/i-play-with-my-little-friend-pipi-and-feel-good/

tamiflu over the counter bronchial inhalers over the counter

College Girls Porn Pics

http://violentsexyporn.allproblog.com/?post-eileen

sabian porn biggy smalls porn animetube porn male porn secrets porn star careena collins

I am really loving the theme/design of your website.

Do you ever run into any browser compatibility issues?

A few of my blog readers have complained about my website not operating

correctly in Explorer but looks great in Opera. Do you have any advice to help fix this problem?

Your style is so unique in comparison to other people I’ve read stuff

from. Thanks for posting when you have the opportunity, Guess I’ll just bookmark this web site.

Fantastic goods from you, man. I’ve understand your stuff

previous to and you’re just extremely fantastic. I really like what you’ve acquired here, really like what you’re stating and the way in which you say it.

You make it enjoyable and you still care for to keep it wise.

I can not wait to read much more from you. This is actually a tremendous

web site.

I know this if off topic but I’m looking into starting my own weblog and

was wondering what all is needed to get setup?

I’m assuming having a blog like yours would cost a pretty penny?

I’m not very internet smart so I’m not 100% sure.

Any tips or advice would be greatly appreciated. Many thanks

Wow, this post is nice, my younger sister is analyzing these kinds of things, thus I am going to

tell her.

歐客佬精品咖啡 |OKLAO COFFEE|蝦皮商城|咖啡豆|掛耳|精品咖啡|咖啡禮盒 專賣|精品麵包

https://first-cafe.com/

Делюсь ссылкой на интересный сайт myledy.ru

здесь куча полезной информации. эзотерика, мода, психология

http://www.ipron.com/communication/forum/index.php?PAGE_NAME=message&FID=4&TID=202962&MID=575837&result=new#message575837

http://forum.inphtech.pt/viewtopic.php?t=251188

http://www.kalyamalya.ru/modules/newbb_plus/viewtopic.php?topic_id=11108&post_id=84932&order=0&viewmode=flat&pid=0&forum=4#84932

If some one desires to be updated with hottest technologies therefore he must be

visit this web page and be up to date all the time.

http://rostov-on-ice.ru/sorevnovatelnaya-osen-2017.html/img-20171129-wa0009-1

Attractive section of content. I simply stumbled upon your blog and

in accession capital to say that I acquire in fact loved account your

blog posts. Anyway I’ll be subscribing for your feeds or even I fulfillment

you access consistently fast.

You actuallʏ maҝе it serm soo easy ᴡith yoսr presentation ƅut Ӏ find thiѕ topic to

be really sommething tһat I think Iwoupd neѵer understand.

Ιt sеems too complex and very broad foг me.

I аm lօoking forward fоr yoour next post, I wiⅼl tгy to get the hang оf it!

My web site: mandala tapestry

best sleeping pills over the counter the best over counter sleep aid

I’ll right away gra yoyr rss aas I can not in finding

your e-mail subscription hyperlink or e-newsletter service.

Do you have any? Pleasxe allow me realize in order

thyat I could subscribe. Thanks.

my web-site … pmp exam simulator (Quyen)

I go to see each day a few sites and information sites to read content, except this website

offers feature based writing.

Hot galleries, thousands new daily.

http://pornrabbi.jsutandy.com/?post-jaelyn

leather bound dykes porn photo still insatiable porn movie british porn pubic shaving sister midnight porn midet porn

http://www.samaramed.ru/advert/services/info_11958.html

Let me give you a thumbs up man. Can I tell you exactly how to do amazing values and if you want

to really findout? and also share valuable info about how to change your life yalla lready know follow me my fellow commenters!.

Hi there, always i used to check webpage posts here early in the dawn, for the reason that i like to find out more and more.

467

I believe people who wrote this needs true loving because it’s a blessing.

So let me give back and show my hidden information on change your life and if

you want to really findout? I will share info about howto make money Don’t forget..

I am always here for yall. Bless yall!

Have you ever thought about adding a little bit more than just your

articles? I mean, what you say is important and all. However just

imagine if you added some great pictures or videos to give your posts

more, “pop”! Your content is excellent but with pics and videos, this site could definitely

be one of the greatest in its field. Great blog!

Hi there! I just want tо giѵе you ɑ huge thumbs ᥙp for youг excellent information үou hɑve right hегe on this post.

I’ll be ⅽoming bacck tо yߋur blog for more soon.

Visut my blog post Cbd Stores Near Me

http://torowe.pl/viewtopic.php?f=12&t=502131&sid=fa85d90e8eab1fb6e2d125dba85fefc0

My developer is trying to persuade me to move to .net from PHP.

I have always disliked the idea because of the expenses.

But he’s tryiong none the less. I’ve been using Movable-type on various websites for

about a year and am anxious about switching to

another platform. I have heard great things about blogengine.net.

Is there a way I can import all my wordpress posts

into it? Any kind of help would be greatly appreciated!

詠春拳幣

https://etherscan.io/token/0xa8930ee8906063d2a5c7ea15b6b4429463d28f58

I’m extremely inspired with your writing abilities as well as with the structure to your weblog. Is that this a paid topic or did you customize it yourself? Anyway keep up the nice high quality writing, it is rare to see a nice weblog like this one these days..

I am really glad to glance at this webpage posts which contains lots of useful facts, thanks for providing

these kinds of data.

I was suggested this website by my cousin. I am

not sure whether this post is written by him as no one else know

such detailed about my trouble. You are amazing! Thanks!

I do not even know the way I finished up here,

but I thought this put up was once great. I don’t realize who you’re however definitely you’re going to a famous blogger if you are not already.

Cheers!

I read this post completely about the difference of newest and earlier technologies, it’s amazing article.

Nice blog here! Also your website loads up very fast! What host are

you using? Can I get your affiliate link to your host?

I wish my site loaded up as fast as yours lol

Hey! I could have sworn I’ve been to this blog

before but after checking through some of the post I realized it’s new to me.

Anyhow, I’m definitely happy I found it and I’ll

be bookmarking and checking back frequently!

Hi , I do believe this is an excellent blog. I stumbled upon it on Yahoo , i will come back once again. Money and freedom is the best way to change, may you be rich and help other people.

Its not my first time to pay a visit this web page, i am

visiting this site dailly and obtain fastidious information from here all the time.

Nice blog right here! Additionally your web site lots up very fast!

What host are you the usage of? Can I am getting your associate hyperlink in your host?

I desire my site loaded up as quickly as yours lol

Hello just wanted to give you a quick heads up.

The words in your article seem to be running off the screen in Ie.

I’m not sure if this is a formatting issue or something to do

with internet browser compatibility but I thought I’d post to let you

know. The design and style look great though!

Hope you get the problem solved soon. Many thanks

автоматический вход https://www.pinterest.fr/pin/576883033537311112/

I have to thank you for the efforts you’ve put in penning

this blog. I’m hoping to view the same high-grade content

from you later on as well. In truth, your creative writing abilities has

motivated me to get my own website now 😉

Write more, thats all I have to say. Literally, it seems as though you relied on the video to make your

point. You definitely know what youre talking about,

why waste your intelligence on just posting videos to your blog when you could be giving us

something informative to read?

Howdy! This post could not be written any better!

Reading through this post reminds me of my old room mate!

He always kept talking about this. I will forward this page to him.

Pretty sure he will have a good read. Thank you for sharing!

Sexy pictures each day

http://leatherstrapons.buttplug.instasexyblog.com/?post-raegan

free porn movies thumbnails maloletki porn free porn video sex movies bbw porn site reviews shool teacher porn

You can certainly see your enthusiasm in the work you write. The world hopes for even more passionate writers like you who are not afraid to say how they believe. Always follow your heart.

Terrific knowledge Thanks a lot!

Also visit my blog post – http://bigtreeomc.com/bbs/board.php?bo_table=free&wr_id=19242

Free Porn Galleries – Hot Sex Pictures

http://bestcouplessextoys2016.dudeporn69.com/?erika

porn video collection dad try son porn free super high definition porn abhishek and aishwarya porn young girl 13 porn

It’s perfect time to make some plans for the future and it is

time to be happy. I have read this publish and if I

may just I desire to recommend you some fascinating issues or tips.

Maybe you could write subsequent articles regarding this article.

I wish to read more issues about it!

https://club2108.ru/forum/viewtopic.php?pid=166654#p166654

you can try here https://hotproducthealth.space/aut/cat-id-18/product-nanovein/

I was excited to discover this site. I wanted to

thank you for ones time for this wonderful read!!

I definitely appreciated every part of it and i also have you saved as a favorite to check out new

stuff on your blog.

This is a topic close to my heart cheers, where are your contact details though?

bitcoin casino

Привет планируешь начать инвестировать, не забывай следить на новостями на сайте biznesstrah.ru

It is with both joy and a good little sadness that

we announce that TC3 is transitioning into a good new formatting.

The content of TC3 shall get migrated, in the shape of an anthology, to the innovative OpenAccess guide series „Translation and Multilingual All natural Language Refinement” (http://langsci-press.org/catalog/series/TMNLP, TMNLP) at LangSci Click. The first journal web page features been recently finished down and offers shifted to this short-term location, at which the journal capabilities experience been recently eliminated but the content includes happened to be preserved. In the interim, TMNLP offers experienced its very first very successful matter, with about 1,500 downloads from numerous locations within the initial two calendar months after showing up; this year further issues are already in the pipeline and are to appear.

We as well believe that that with our latest format we can work the network far better: on leading of modified quantities, which have been the power of TC3, we can right now likewise publish monographs (integrating dissertations). We happen to be looking to latest endeavours forward!

When I originally commented I clicked the “Notify me when new comments are added” checkbox and now

each time a comment is added I get three emails with

the same comment. Is there any way you can remove me from that service?

Thank you!

I’ve read several good stuff here. Definitely price bookmarking

for revisiting. I wonder how so much attempt you set

to create such a excellent informative website.

It is appropriate time to make some plans for the future and it is

time to be happy. I’ve read this post and if I could I wish to suggest you some interesting things or tips.

Maybe you could write next articles referring to this article.

I want to read even more things about it!

their explanation https://hotmedicy.space/tur/tvr-684/

What’s Happening i’m new to this, I stumbled upon this I’ve found It absolutely useful

and it has aided me out loads. I’m hoping to give a

contribution & help different users like its helped me.

Good job.

Букмекерская контора 1win продолжает радовать своих клиентов отличными возможностями для ставок.

Многие новые клиенты регистрируются сегодня на официальном сайте 1вин.рф, довольные и постоянные посетители сайта БК

предлагают им хорошие условия.

cсылка на регистрацию:1win зеркало

Thank you, I’ve recently been looking for info about this subject for a

long time and yours is the greatest I’ve found out so far.

But, what in regards to the bottom line? Are you positive concerning the supply?

http://kvartal8b.getbb.ru/viewtopic.php?f=19&t=7719

is ivermectin over the counter over the counter medication for uti

postingan ini tak ternilai. Di mana saya dapat mengetahui lebih lanjut?

saya untuk mengambil feed Anda agar tetap diperbarui dengan pos yang akan datang.

Terima kasih banyak dan tolong lanjutkan pekerjaan menghargai.|

Bermanfaat informasi. Beruntung saya Saya menemukan situs web Anda tidak sengaja, dan Saya terkejut mengapa perubahan nasib

ini tidak terjadi sebelumnya! Saya menandainya.|

Apakah Anda memiliki masalah spam di blog ini; Saya juga seorang blogger,

dan saya bertanya-tanya situasi Anda; kami

telah mengembangkan beberapa prosedur yang bagus dan kami ingin menukar strategi dengan orang lain , pastikan tembak saya email jika tertarik.|

Ini sangat menarik, Kamu blogger yang sangat terampil.

Saya telah bergabung dengan feed Anda dan berharap untuk mencari lebih banyak postingan luar biasa Anda.

Juga, Saya telah membagikan situs Anda di jejaring sosial saya!|

Saya berpikir bahwa apa yang Anda diposting adalah

sangat masuk akal. Tapi, bagaimana dengan ini? bagaimana jika Anda menambahkan sedikit informasi?

Maksud saya, saya tidak ingin memberi tahu Anda cara menjalankan blog Anda, tetapi bagaimana jika

Anda menambahkan a judul yang membuat orang keinginan lebih?

Maksud saya Nozzle Sizes, Materials, and Shapes for 3D Printers – Fargo 3D Printing

agak polos. Anda bisa melihat di halaman depan Yahoo

dan melihat bagaimana mereka membuat posting headlines untuk

mendapatkan pemirsa tertarik. Anda dapat menambahkan video atau

gambar atau dua untuk mendapatkan orang bersemangat tentang semuanya telah harus dikatakan. Hanya pendapat saya,

itu akan membuat situs web Anda sedikit lebih menarik.|

Luar Biasa situs web yang Anda miliki di sini, tetapi saya ingin tahu tentang apakah Anda mengetahui forum

komunitas yang mencakup topik yang sama dibahas dalam artikel ini?

Saya sangat suka untuk menjadi bagian dari komunitas online tempat

saya bisa mendapatkan komentar dari berpengalaman lainnya } individu yang memiliki minat yang sama.

Jika Anda memiliki saran, beri tahu saya. Cheers!|

Halo sangat baik situs web!! Pria .. Luar biasa ..

Luar biasa .. Saya akan menandai blog Anda dan mengambil feed

tambahan? Saya bahagia menemukan begitu banyak berguna informasi

di sini dalam kirim, kami ingin berlatih ekstra

teknik dalam hal ini, terima kasih telah berbagi. . . .

. .|

Hari ini, saya pergi ke tepi pantai bersama anak-anak saya.

Saya menemukan kerang laut dan memberikannya kepada putri saya yang berusia 4 tahun dan berkata, “Kamu dapat mendengar lautan jika kamu meletakkannya di telingamu.” Dia

meletakkan cangkang ke telinganya dan berteriak. Ada

kelomang di dalamnya dan menjepit telinganya. Dia tidak pernah

ingin kembali! LoL Saya tahu ini benar-benar di

luar topik tetapi saya harus memberi tahu seseorang!|

Teruslah menulis, kerja bagus!|

Hei, saya tahu ini di luar topik tapi saya bertanya-tanyang jika

Anda mengetahui widget apa pun yang dapat saya tambahkan ke blog saya yang secara otomatis men-tweet pembaruan twitter terbaru saya.

Saya telah mencari plug-in seperti ini selama beberapa waktu dan berharap

mungkin Anda akan memiliki pengalaman dengan hal seperti ini.

Tolong beri tahu saya jika Anda mengalami sesuatu. Saya sangat menikmati

membaca blog Anda dan saya menantikan pembaruan baru Anda.|

Pada saat ini tampak seperti Movable Type adalah platform

blogging pilihan di luar sana sekarang juga. (dari apa yang saya baca) Apakah itu yang kamu gunakan di blogmu?|

Aduh, ini sangat postingan bagus. Meluangkan waktu dan upaya nyata untuk membuat top

notch artikel… tapi apa yang bisa saya katakan… Saya ragu-ragu banyak sekali dan tidak pernah tampaknya

mendapatkan apa pun selesai.|

Wow itu tidak biasa. Saya baru saja menulis komentar yang sangat panjang tetapi setelah saya mengklik kirim, komentar saya tidak

muncul. Grrrr… baik saya tidak menulis semua itu lagi.

Ngomong-ngomong, hanya ingin mengatakan blog luar biasa!|

WOW apa yang saya cari. Datang ke sini dengan mencari dipo4d gacor|

Hebat artikel. Terus memposting informasi semacam itu di

halaman Anda. Saya sangat terkesan dengan blog Anda.

Hai di sana, Anda telah melakukan pekerjaan luar biasa.

Saya akan pasti menggalinya dan secara pribadi merekomendasikan kepada teman-teman saya.

Saya percaya diri mereka akan mendapat manfaat dari situs ini.|

Bolehkah saya hanya mengatakan apa bantuan untuk menemukan seseorang yang benar-benar tahu apa

mereka berbicara tentang di internet. Anda tentu memahami cara membawa suatu masalah ke terang dan menjadikannya penting.

Lebih banyak orang perlu lihat ini dan pahami sisi ini dari kisah Anda.

Saya terkejut kamu tidak lebih populer mengingat bahwa kamu pasti memiliki hadiah.|

Suatu hari, ketika saya sedang bekerja, saudara perempuan saya mencuri iphone saya

dan menguji untuk melihat apakah dapat bertahan dalam tiga puluh foot drop, supaya

dia bisa jadi sensasi youtube. iPad saya sekarang rusak dan dia memiliki

83 tampilan. Saya tahu ini benar-benar di luar topik tetapi

saya harus membaginya dengan seseorang!|

Halo! Apakah Anda keberatan jika saya membagikan blog Anda dengan grup myspace saya?

Ada banyak orang yang menurut saya akan sangat menikmati

konten Anda. Tolong beritahu saya. Terima kasih|

Halo! Posting ini tidak bisa ditulis lebih baik!

Membaca postingan ini mengingatkan saya pada

teman sekamar lama yang baik! Dia selalu terus berbicara tentang ini.

Saya akan meneruskan tulisan ini kepadanya. Cukup

yakin dia akan membaca dengan baik. Terima kasih

telah berbagi!|

Halo! Tahukah Anda jika mereka membuat plugin untuk melindungi dari peretas?

Saya agak paranoid tentang kehilangan semua yang telah saya

kerjakan dengan keras. Ada saran?|

Anda adalah sebenarnya seorang webmaster tepat. situs web memuat kecepatan luar

biasa. Rasanya kamu melakukan trik khas. Juga, Isinya adalah masterpiece.

Anda telah melakukan fantastis tugas pada hal ini subjek!|

Halo! Saya tahu ini semacamf-topic namun Saya harus

untuk bertanya. Apakah menjalankan blog yang mapan seperti milik Anda membutuhkan jumlah besar berfungsi?

Saya baru untuk blogging tetapi saya menulis di buku harian saya setiap hari.

Saya ingin memulai sebuah blog sehingga saya dapat berbagi pengalaman dan pikiran saya secara online.

Harap beri tahu saya jika Anda memiliki segala jenis rekomendasi atau

kiat untuk merek baru calon pemilik blog. Terima kasih!|

Hmm apakah ada orang lain yang mengalami masalah dengan gambar di pemuatan blog ini?

Saya mencoba untuk menentukan apakah itu masalah di pihak saya atau apakah itu blog.

Setiap tanggapan akan sangat dihargai.|

Halo hanya ingin memberi Anda informasi brief dan memberi tahu

Anda bahwa beberapa gambar tidak dimuat dengan baik.

Saya tidak yakin mengapa tetapi saya pikir ini masalah

penautan. Saya sudah mencobanya di dua web browser yang berbeda dan keduanya menunjukkan hasil yang sama.|

Halo hebat blog! Apakah menjalankan blog seperti ini memerlukan jumlah besar berhasil?

Saya hampir tidak pemahaman pemrograman komputer namun saya pernah berharap untuk memulai blog saya sendiri

in the near future. Bagaimanapun, jika Anda memiliki saran atau

tips untuk pemilik blog baru, silakan bagikan. Saya mengerti ini

di luar subjek tetapi Saya hanya perlu bertanya. Terima kasih banyak!|

Halo! Saya sedang bekerja menjelajahi blog Anda dari apple iphone baru saya!

Hanya ingin mengatakan bahwa saya suka membaca blog

Anda dan menantikan semua postingan Anda! Teruskan pekerjaan luar biasa!|

Halo! Ini agak di luar topik, tetapi saya memerlukan beberapa saran dari blog yang

sudah mapan. Apakah sulit untuk membuat blog Anda sendiri?

Saya tidak terlalu teknis tetapi saya dapat memecahkan masalah

dengan cukup cepat. Saya berpikir untuk membuat milik saya sendiri, tetapi saya tidak yakin harus

mulai dari mana. Apakah Anda punya tips atau saran? Dengan terima kasih|

Halo! Apakah Anda menggunakan Twitter? Saya ingin mengikuti Anda jika itu oke.

Saya tidak diragukan lagi menikmati blog Anda dan menantikan postingan baru.|

Hei disana, Anda telah melakukan pekerjaan hebat. Saya akan pasti menggalinya dan secara pribadi merekomendasikan kepada teman-teman saya.

Saya yakin mereka akan mendapat manfaat dari situs web ini.|

Halo! Tahukah Anda jika mereka membuat plugin untuk membantu dengan Search Engine Optimization? Saya mencoba membuat peringkat blog

saya untuk beberapa kata kunci yang ditargetkan tetapi saya tidak melihat keuntungan yang sangat baik.

Jika Anda tahu ada tolong bagikan. Cheers!|

Halo ini agak di luar topik tapi saya ingin tahu apakah blog menggunakan editor WYSIWYG atau jika Anda

harus membuat kode secara manual dengan HTML. Saya akan segera memulai blog tetapi tidak

memiliki keahlian pengkodean jadi saya ingin mendapatkan saran dari seseorang

yang berpengalaman. Bantuan apa pun akan sangat dihargai!|

Ini adalah pertama kalinya saya kunjungi di sini dan saya benar-benar terkesan untuk membaca segalanya di tempat satu.|

Ini seperti Anda membaca pikiran saya! Anda tampaknya tahu begitu banyak tentang ini, seperti Anda menulis

buku di dalamnya atau semacamnya. Saya pikir Anda dapat melakukannya dengan beberapa foto untuk mengarahkan pesan ke rumah sedikit, tetapi selain itu, ini luar biasa blog.

Bagus bacaan. Saya akan pasti akan kembali.|

Wow, luar biasa! Sudah berapa lama Anda ngeblog? Anda membuat blogging terlihat

mudah. Tampilan keseluruhan situs web Anda luar biasa, serta kontennya!|

Wow, luar biasa weblog tata letak! Sudah berapa panjang pernah blogging?

Anda membuat blogging terlihat mudah. Seluruh Sekilas situs Anda fantastis, apalagi

konten!

}

Loving the info on this site, you have done great job on the posts.

my web site :: ccna exams (Broderick)

wellbutrin 450 xl

Heya aku untuk pertama kali di sini. Saya menemukan papan ini dan saya menemukan Ini benar-benar berguna

& membantu saya banyak. Saya berharap untuk mempersembahkan satu hal lagi dan membantu

orang lain seperti kamu membantu saya. saya untuk

mengambil feed Anda agar tetap terkini dengan pos yang akan datang.

Terima kasih banyak dan tolong teruskan pekerjaan menghargai.|

Berharga informasi. Beruntung saya Saya menemukan situs web Anda

secara kebetulan, dan Saya terkejut mengapa kecelakaan ini tidak terjadi sebelumnya!

Saya menandainya.|

Apakah Anda memiliki masalah spam di situs ini; Saya juga seorang blogger, dan saya

bertanya-tanya situasi Anda; kami telah membuat beberapa metode yang bagus

dan kami ingin pertukaran metode dengan orang lain , tolong tembak saya email

jika tertarik.|

Ini sangat menarik, Kamu blogger yang sangat terampil.

Saya telah bergabung dengan feed Anda dan berharap untuk mencari lebih banyak postingan fantastis Anda.

Juga, Saya telah membagikan situs web Anda di jejaring sosial saya!|

Saya berpikir bahwa apa yang Anda menulis sebenarnya sangat masuk akal.

Tapi, pertimbangkan ini, misalkan Anda akan menciptakan mengagumkan headline?

Maksud saya, saya tidak ingin memberi tahu Anda cara

menjalankan blog Anda, namun bagaimana jika Anda menambahkan a

headline untuk mungkin menarik perhatian rakyat?

Maksud saya Nozzle Sizes, Materials, and Shapes for 3D Printers – Fargo

3D Printing sedikit membosankan. Anda harus mengintip di halaman beranda

Yahoo dan melihat bagaimana mereka membuat posting headlines untuk ambil orang

untuk membuka tautan. Anda dapat mencoba menambahkan video

atau gambar terkait atau dua untuk ambil orang bersemangat

tentang semuanya telah harus dikatakan. Menurut pendapat saya, itu bisa membuat situs web Anda sedikit lebih hidup.|

Sangat bagus blog yang Anda miliki di sini, tetapi saya

ingin tahu tentang apakah Anda mengetahui forum diskusi pengguna yang mencakup topik

yang sama dibicarakan di sini? Saya sangat suka untuk menjadi bagian dari komunitas online tempat saya

bisa mendapatkan komentar dari berpengetahuan lainnya } orang yang memiliki minat yang sama.

Jika Anda memiliki saran, beri tahu saya. Terima kasih

banyak!|

Apa kabar sangat keren situs!! Pria .. Cantik .. Luar biasa ..

Saya akan menandai situs web Anda dan mengambil feed juga?

Saya senang mencari begitu banyak bermanfaat info di sini di publikasikan, kami ingin mengembangkan ekstra teknik dalam

hal ini, terima kasih telah berbagi. . . . . .|

Hari ini, saya pergi ke tepi pantai bersama anak-anak saya.

Saya menemukan kerang laut dan memberikannya kepada putri saya yang berusia 4 tahun dan berkata, “Kamu dapat mendengar lautan jika kamu meletakkannya di telingamu.” Dia meletakkan cangkang ke telinganya dan berteriak.

Ada kelomang di dalamnya dan menjepit telinganya.

Dia tidak pernah ingin kembali! LoL Saya tahu ini sepenuhnya

di luar topik tetapi saya harus memberi tahu seseorang!|

Teruslah terus bekerja, kerja bagus!|

Hei, saya tahu ini di luar topik tapi saya bertanya-tanyang jika

Anda mengetahui widget apa pun yang dapat saya tambahkan ke blog saya yang

secara otomatis men-tweet pembaruan twitter terbaru saya.

Saya telah mencari plug-in seperti ini selama beberapa waktu dan berharap mungkin Anda akan memiliki pengalaman dengan hal seperti ini.

Tolong beri tahu saya jika Anda mengalami sesuatu. Saya sangat menikmati membaca blog

Anda dan saya menantikan pembaruan baru Anda.|

Saat ini tampaknya seperti Expression Engine adalah platform blogging teratas

di luar sana sekarang juga. (dari apa yang saya baca) Apakah itu yang kamu gunakan di

blogmu?|

Aduh, ini luar biasa postingan bagus. Meluangkan waktu dan upaya nyata untuk

membuat hebat artikel… tapi apa yang bisa saya katakan…

Saya menunda banyak dan tidak berhasil mendapatkan hampir semua hal selesai.|

Wow itu aneh. Saya baru saja menulis komentar yang sangat panjang tetapi setelah saya mengklik

kirim, komentar saya tidak muncul. Grrrr… baik saya tidak menulis semua itu lagi.

Pokoknya, hanya ingin mengatakan blog luar biasa!|

WOW apa yang saya cari. Datang ke sini dengan mencari

daftar babetoto|

Luar biasa postingan. Terus memposting info semacam itu di halaman Anda.

Saya sangat terkesan dengan blog Anda.

Hai di sana, Anda telah melakukan pekerjaan luar biasa.

Saya akan pasti menggalinya dan untuk bagian saya menyarankan kepada teman-teman saya.

Saya percaya diri mereka akan mendapat manfaat dari

situs ini.|

Bolehkah saya sederhana mengatakan apa kenyamanan untuk mengungkap seseorang yang

sebenarnya mengerti apa mereka berdiskusi di web. Anda

tentu tahu bagaimana membawa suatu masalah ke terang dan menjadikannya penting.

Lebih banyak orang harus lihat ini dan pahami sisi ini dari Anda.

Saya terkejut kamu tidak lebih populer sejak kamu tentu memiliki hadiah.|

Hari ini, ketika saya sedang bekerja, saudara perempuan saya mencuri iPad saya dan menguji untuk melihat apakah dapat bertahan dalam 25 foot drop, supaya

dia bisa jadi sensasi youtube. apple ipad saya sekarang rusak dan dia memiliki 83 tampilan. Saya tahu ini sepenuhnya di luar topik tetapi saya harus membaginya dengan seseorang!|

Halo! Apakah Anda keberatan jika saya membagikan blog Anda dengan grup

myspace saya? Ada banyak orang yang menurut saya akan sangat menghargai konten Anda.

Tolong beritahu saya. Terima kasih|

Selamat siang! Posting ini tidak bisa ditulis lebih baik!

Membaca postingan ini mengingatkan saya pada teman sekamar lama yang baik!

Dia selalu terus mengobrol tentang ini. Saya akan meneruskan tulisan ini

kepadanya. Cukup yakin dia akan membaca dengan baik.

Terima kasih telah berbagi!|

Halo! Tahukah Anda jika mereka membuat plugin untuk melindungi dari

peretas? Saya agak paranoid tentang kehilangan semua yang telah saya

kerjakan dengan keras. Ada rekomendasi?|

Anda benar-benar seorang webmaster luar biasa. situs web memuat kecepatan luar

biasa. Rasanya kamu melakukan trik khas. Selanjutnya, Isinya adalah masterwork.

Anda memiliki melakukan hebat pekerjaan pada hal ini subjek!|

Hei! Saya sadar ini semacamf-topic namun Saya harus untuk bertanya.

Apakah mengoperasikan situs web yang mapan seperti milik Anda mengambil jumlah besar berfungsi?

Saya baru untuk blogging namun saya menulis di buku

harian saya setiap hari. Saya ingin memulai sebuah blog

sehingga saya akan dapat berbagi pengalaman dan pandangan milik saya secara online.

Harap beri tahu saya jika Anda memiliki apa pun rekomendasi atau kiat untuk merek baru calon blogger.

Terima kasih!|

Hmm apakah ada orang lain yang mengalami masalah dengan gambar

di pemuatan blog ini? Saya mencoba untuk mencari tahu apakah itu

masalah di pihak saya atau apakah itu blog. Setiap masukan akan sangat dihargai.|

Halo hanya ingin memberi Anda informasi brief dan memberi tahu Anda bahwa beberapa gambar tidak dimuat

dengan baik. Saya tidak yakin mengapa tetapi saya pikir

ini masalah penautan. Saya sudah mencobanya di dua internet browser yang berbeda dan keduanya menunjukkan hasil yang sama.|

Halo fantastis blog! Apakah menjalankan blog seperti ini mengambil sejumlah besar berhasil?

Saya punya hampir tidak pengetahuan tentang pemrograman namun saya

dulu berharap untuk memulai blog saya sendiri in the near future.

Pokoknya, jika Anda memiliki saran atau tips untuk pemilik blog baru, silakan bagikan. Saya mengerti ini di luar

topik namun demikian Saya hanya ingin bertanya. Terima kasih!|

Halo! Saya sedang bekerja browsing blog Anda dari iphone baru saya!

Hanya ingin mengatakan bahwa saya suka membaca blog Anda

dan menantikan semua postingan Anda! Teruskan pekerjaan luar biasa!|

Halo! Ini agak di luar topik, tetapi saya memerlukan beberapa bantuan dari blog yang sudah mapan. Apakah sulit untuk membuat blog Anda sendiri?

Saya tidak terlalu teknis tetapi saya dapat memecahkan masalah dengan cukup cepat.

Saya berpikir untuk membuat milik saya sendiri, tetapi saya tidak yakin harus mulai dari

mana. Apakah Anda punya tips atau saran? Terima kasih

banyak|

Halo! Apakah Anda menggunakan Twitter? Saya ingin mengikuti Anda jika itu

oke. Saya pasti menikmati blog Anda dan menantikan postingan baru.|

Hei disana, Anda telah melakukan pekerjaan hebat.

Saya akan pasti menggalinya dan secara pribadi merekomendasikan kepada teman-teman saya.

Saya yakin mereka akan mendapat manfaat dari situs

web ini.|

Halo! Tahukah Anda jika mereka membuat plugin untuk help dengan Search Engine Optimization? Saya mencoba membuat peringkat blog

saya untuk beberapa kata kunci yang ditargetkan tetapi saya

tidak melihat keuntungan yang sangat baik. Jika Anda tahu ada

tolong bagikan. Terima kasih banyak!|

Halo ini semacam di luar topik tapi saya ingin tahu apakah blog menggunakan editor

WYSIWYG atau jika Anda harus membuat kode secara manual dengan HTML.

Saya akan segera memulai blog tetapi tidak memiliki

keterampilan pengkodean jadi saya ingin mendapatkan bimbingan dari seseorang yang berpengalaman. Bantuan apa pun akan sangat dihargai!|

Ini adalah pertama kalinya saya pergi untuk melihat di sini dan saya

benar-benar terkesan untuk membaca segalanya di tempat satu.|

Ini seperti Anda membaca pikiran saya! Anda tampaknya tahu

banyak tentang ini, seperti Anda menulis buku di

dalamnya atau semacamnya. Saya pikir Anda

dapat melakukannya dengan beberapa foto

untuk mengarahkan pesan ke rumah sedikit, tetapi selain itu, ini luar biasa blog.

Bagus bacaan. Saya akan pasti akan kembali.|

Wow, luar biasa! Sudah berapa lama Anda ngeblog?

Anda membuat blogging terlihat mudah. Tampilan keseluruhan situs Anda

fantastis, apalagi kontennya!|