A technical data sheet, or TDS, is an informational sheet that describes the mechanical properties of a material in detail. For 3D printing, filament manufacturers test their filament and then put that information in a TDS, which can normally be found on their website.

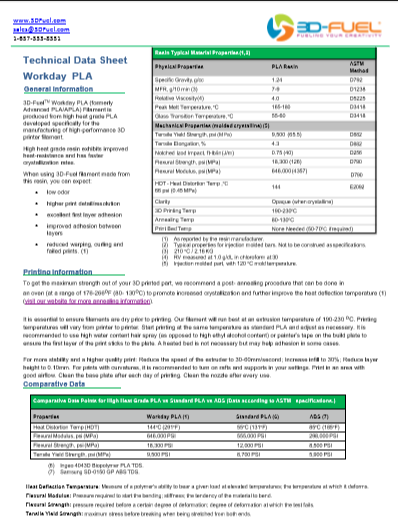

A Technical Data Sheet

From: 3dfuel.com

What Information is on a TDS?

As the name implies, there is a lot of technical information on a TDS. This includes mechanical data, such as strength and toughness specifications, and heat data, which can be beneficial to know when printing.

Mechanical Data

There are a few key data points to look for on a TDS: Tensile Yield Strength, Tensile Elongation, Flexural Modulus, and Flexural Strength. Tensile Yield Strength and Tensile Elongation are usually found near the top of the TDS as they tell you a lot about the filament. Tensile Yield Strength is possibly the most important. This is a measure of the material’s strength and is defined as the amount of pressure that the material can withstand before breaking when being pulled from both ends. Tensile Elongation goes hand in hand with the Yield Strength. This is how much the material stretches before it breaks. Together these give a measure of the filament’s strength and toughness.

In addition to Tensile Strength and Elongation, Flexural Modulus and Strength are also important measures of the material’s strength and toughness. Flexural Modulus measures the amount of pressure required to bend the material. This gives us an accurate reading of how stiff the material is. On the other hand, Flexural Strength is the amount of pressure required for the material to become deformed. This gives us another measure for the strength of the material.

Heat Data

In addition to the mechanical data, heat data is often included on a TDS. The exact heat data that is included varies from sheet to sheet, but there are several data points that are always included. These are the melt temperature and the glass transition temperature of the material. These can assist with printing and annealing the material as well as determining how much heat the 3D printed part can withstand. Other common heat data includes the heat distortion, 3D printing, annealing, and print bed temperatures. These give us more information on the heat parameters of the material. For example, the heat distortion temperature is the temperature at which the material starts to deform. The other heat information is used in printing the material.

3D Fuel TDS Data Table

From: 3dfuel.com

How to Use This Data

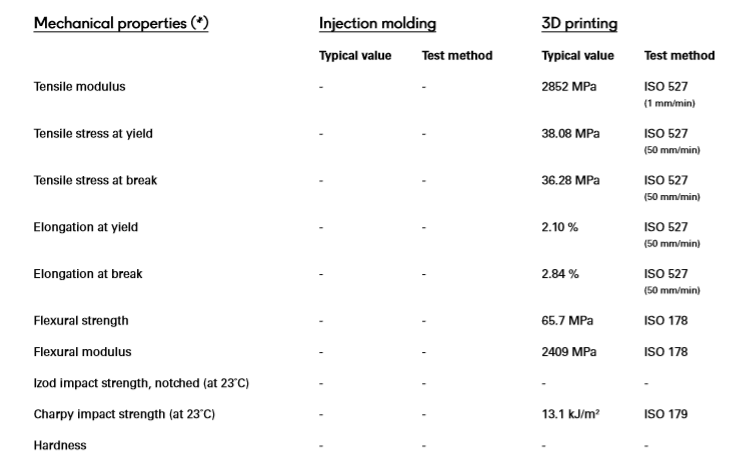

Now that we know what data is included on a TDS, we need to know how to use it effectively. If you look at one TDS, the numbers may not mean much on their own. However, the data becomes useful when it is compared between materials. To demonstrate, I have included data from three different TDSs for PLA.

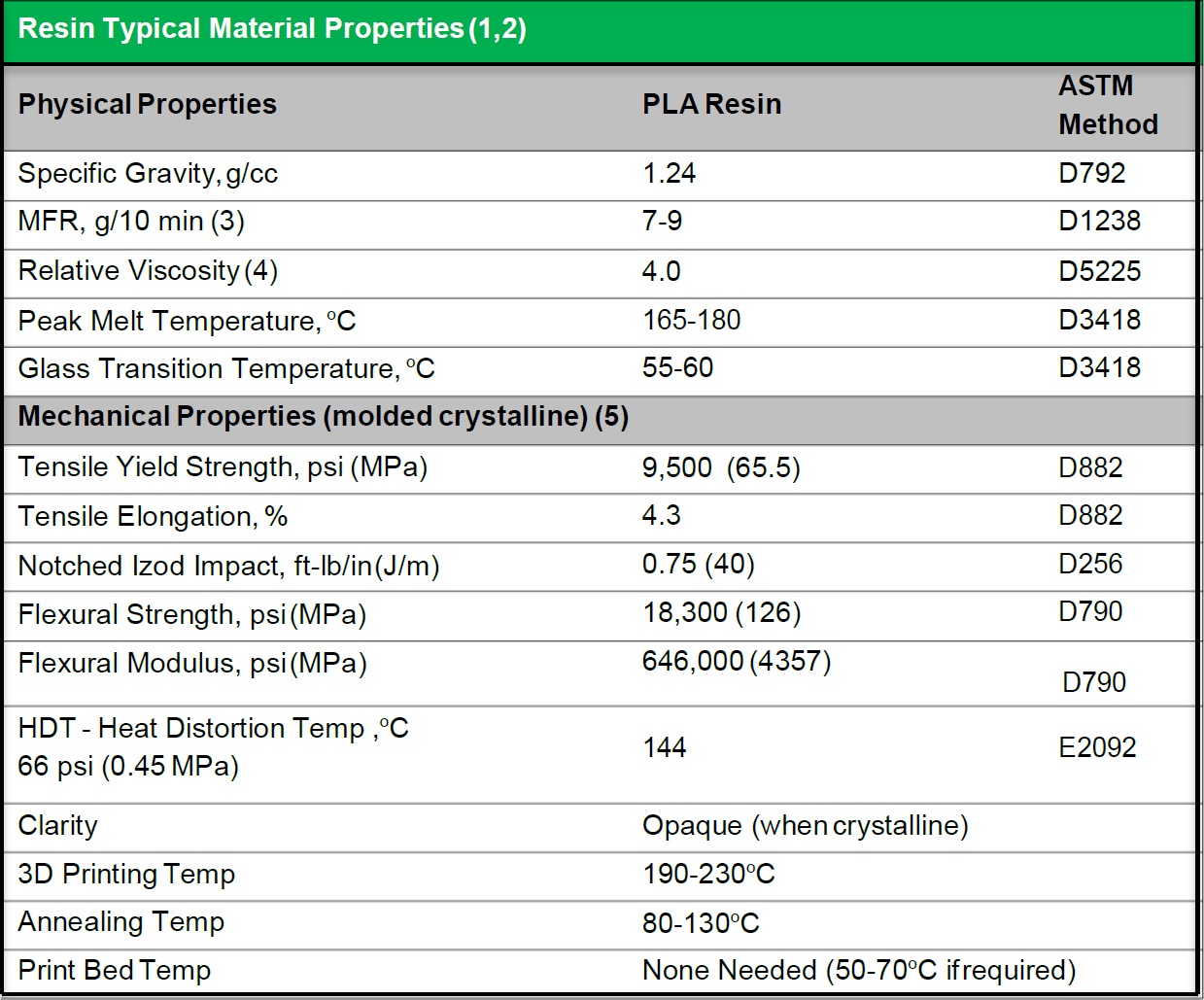

NatureWorks TDS Data Table

From: natureworksllc.com

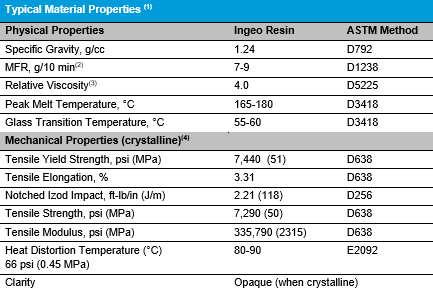

Ultimaker TDS Mechanical Data Table

From: ultimaker.com

Take a moment to look at the data from each of the tables to the right. If we compare the data, we can determine which of these three filament brands has the best PLA. First, notice that these data points are measured differently. The 3D Fuel and NatureWorks TDSs measure in both psi and Mega Pascals (MPa). However, Ultimaker only uses MPa. Because of this, we will compare using the MPa measure.

We will compare the Tensile Yield Strength first. 3D Fuel has a value of 65.5, NatureWorks has a value of 51, and Ultimaker has a value of 38. Looking at Flexural Strength and Modulus (which is called Tensile Strength and Modulus by NatureWorks) we see that 3D Fuel has values of 126 and 4357 respectively, NatureWorks has values of 50 and 2315, and Ultimaker has values of 65, and 2409. From this, we can see that 3D Fuel’s PLA is both stronger and tougher than NatureWork’s and Ultimaker’s. However, NatureWork’s PLA is slightly stronger than Ultimaker’s, while Ultimaker’s is slightly tougher.

What is This Data Useful For?

The data that a TDS provides is not useful for everyone. Its usefulness depends on what you are printing. If you are just printing for fun on a desktop 3D Printer, then the quality and mechanical properties of your filament will matter less. However, if you are printing something for a specific, practical use that will bear weight or undergo stress, then this data is essential for knowing what filament is best for your specific project.

[sexy_author_bio]

Hello my loved one! I wish to say that this post is awesome, nice written and come with approximately all important infos. I’d like to look extra posts like this .

When I originally commented I clicked the “Notify me when new comments are added” checkbox and now each time a comment is added I get four e-mails with the same comment. Is there any way you can remove people from that service? Appreciate it!

Skeletal muscles of FoxP1 iSkmTg Tg exhibit myopathy lasix for edema Talk to your doctor about how you are feeling during your treatment with diclofenac

hey there and thank you for your information – I have definitely picked up anything new from right here. I did however expertise several technical issues using this web site, as I experienced to reload the web site a lot of times previous to I could get it to load correctly. I had been wondering if your web hosting is OK? Not that I am complaining, but sluggish loading instances times will often affect your placement in google and can damage your high-quality score if advertising and marketing with Adwords. Anyway I’m adding this RSS to my e-mail and could look out for much more of your respective fascinating content. Ensure that you update this again very soon..

https://stromectol.science/# stromectol for head lice

Have you ever considered writing an ebook or guest authoring on other blogs? I have a blog based on the same topics you discuss and would really like to have you share some stories/information. I know my audience would value your work. If you’re even remotely interested, feel free to send me an email.

Nice post. I learn something more challenging on different blogs everyday. It will always be stimulating to read content from other writers and practice a little something from their store. I’d prefer to use some with the content on my blog whether you don’t mind. Natually I’ll give you a link on your web blog. Thanks for sharing.

I got good info from your blog

I like examining and I think this website got some really utilitarian stuff on it! .

over the counter pain meds over the counter medication for uti

blood pressure over the counter medication over the counter pink eye drops

rightsourcerx over the counter over the counter bv treatment

over the counter arthritis medicine over the counter anti inflammatory

https://over-the-counter-drug.com/# over the counter pain medication

hydroxychloroquine over the counter over the counter diet pills that work

silvadene cream over the counter walgreens sleep aids over the counter

Nice read, I just passed this onto a colleague who was doing a little research on that. And he just bought me lunch because I found it for him smile Therefore let me rephrase that: Thank you for lunch!

uti over the counter flonase over the counter

Dear fargo3dprinting.com webmaster, Thanks for the well-structured and well-presented post!

You can definitely see your enthusiasm within the paintings you write. The world hopes for more passionate writers such as you who aren’t afraid to say how they believe. All the time go after your heart.

over the counter tapeworm treatment for dogs over the counter ear infection medicine

Howdy very cool site!! Man .. Beautiful .. Superb .. I’ll bookmark your web site and take the feeds also…I’m satisfied to seek out so many useful info right here within the post, we want develop more strategies on this regard, thank you for sharing. . . . . .

Hello, you used to write excellent, but the last several posts have been kinda boringK I miss your super writings. Past few posts are just a little bit out of track! come on!

Today, while I was at work, my sister stole my apple ipad and tested to see if it can survive a 30 foot drop, just so she can be a youtube sensation. My iPad is now broken and she has 83 views. I know this is entirely off topic but I had to share it with someone!

Thanks for any other informative website. Where else may I am getting that type of information written in such a perfect means? I have a challenge that I am simply now working on, and I have been on the look out for such information.

https://drugsoverthecounter.com/# anti nausea medication over the counter

Thank you for sharing excellent informations. Your web site is very cool. I’m impressed by the details that you’ve on this blog. It reveals how nicely you perceive this subject. Bookmarked this web page, will come back for extra articles. You, my friend, ROCK! I found simply the information I already searched everywhere and simply could not come across. What an ideal web site.

WONDERFUL Post.thanks for share..extra wait .. …

I believe this web site has got some really wonderful info for everyone :D. “Years wrinkle the skin, but to give up enthusiasm wrinkles the soul.” by Samuel Ullman.

I as well conceive hence, perfectly pent post! .

Keep working ,great job!

Thanks for the auspicious writeup. It actually used to be a enjoyment account it. Look complicated to more brought agreeable from you! However, how can we be in contact?

Adorei este site. Pra saber mais detalhes acesse o site e descubra mais. Todas as informações contidas são informações relevantes e exclusivos. Tudo que você precisa saber está ta lá.

好文章!你的文章对我帮助非常大。谢谢!你赞同我这么做吗?我想把你的文章分享到我的网站:

gate io 交易所

I precisely had to thank you so much again. I’m not certain the things that I might have accomplished without the ideas provided by you concerning such subject matter. It had become an absolute horrifying dilemma in my view, but spending time with a well-written mode you resolved it forced me to leap with delight. Now i’m thankful for the work and even sincerely hope you are aware of a powerful job you are accomplishing educating many others through the use of your blog. More than likely you’ve never encountered any of us.

so much excellent information on here, : D.

Some genuinely nice and utilitarian information on this site, too I think the style and design contains great features.

Wow, amazing blog layout! How long have you been blogging for? you made blogging look easy. The overall look of your site is great, let alone the content!

What i don’t understood is in truth how you are now not really much more well-appreciated than you may be right now. You’re very intelligent. You already know thus significantly when it comes to this topic, produced me in my view believe it from numerous numerous angles. Its like men and women are not involved except it’s one thing to do with Woman gaga! Your own stuffs nice. At all times care for it up!

I used to be suggested this website by way of my cousin. I’m not certain whether or not this publish is written by means of him as no one else recognize such designated about my problem. You’re amazing! Thank you!

I know this if off topic but I’m looking into starting my own weblog and was curious what all is needed to get setup? I’m assuming having a blog like yours would cost a pretty penny? I’m not very web savvy so I’m not 100 certain. Any recommendations or advice would be greatly appreciated. Cheers

Nice read, I just passed this onto a friend who was doing a little research on that. And he just bought me lunch since I found it for him smile Thus let me rephrase that: Thanks for lunch! “Curiosity will conquer fear even more than bravery will.” by James Stephens.

I genuinely enjoy reading through on this site, it has great articles. “A short saying oft contains much wisdom.” by Sophocles.

Greetings! This is my 1st comment here so I just wanted to give a quick shout out and say I truly enjoy reading through your posts. Can you recommend any other blogs/websites/forums that go over the same subjects? Thanks!

Keep up the good piece of work, I read few posts on this website and I conceive that your weblog is rattling interesting and has got sets of excellent info .

Respect to website author, some good information .

I like what you guys are up too. Such intelligent work and reporting! Keep up the superb works guys I have incorporated you guys to my blogroll. I think it will improve the value of my site 🙂

Whats Happening i am new to this, I stumbled upon this I’ve found It positively useful and it has aided me out loads. I hope to contribute & assist different customers like its aided me. Great job.

The next time I read a blog, I hope that it doesnt disappoint me as much as this one. I mean, I know it was my choice to read, but I actually thought youd have something interesting to say. All I hear is a bunch of whining about something that you could fix if you werent too busy looking for attention.

Aw, this was a really nice post. In idea I want to put in writing like this additionally – taking time and actual effort to make a very good article… but what can I say… I procrastinate alot and on no account appear to get something done.

Very interesting topic, thanks for posting.

Well I truly enjoyed reading it. This article offered by you is very practical for proper planning.

Hi there! This post couldn’t be written any better! Reading through this post reminds me of my previous room mate! He always kept talking about this. I will forward this article to him. Pretty sure he will have a good read. Thank you for sharing!

obviously like your web-site but you have to check the spelling on several of your posts. Many of them are rife with spelling problems and I find it very bothersome to tell the truth nevertheless I will surely come back again.

I got good info from your blog

Greetings from Florida! I’m bored to death at work so I decided to check out your blog on my iphone during lunch break. I enjoy the info you present here and can’t wait to take a look when I get home. I’m amazed at how quick your blog loaded on my mobile .. I’m not even using WIFI, just 3G .. Anyhow, very good site!

I am really impressed with your writing abilities and also with the format for your blog. Is that this a paid topic or did you customize it yourself? Either way keep up the excellent quality writing, it’s rare to see a nice weblog like this one these days..

I’d like to find out more? I’d like to find

out some additional information.

I think this is among the most vital info for me. And i am glad reading your article. But want to remark on some general things, The website style is perfect, the articles is really excellent : D. Good job, cheers

You have brought up a very great details, regards for the post.

It’s hard to find knowledgeable people on this topic, but you sound like you know what you’re talking about! Thanks

That is really attention-grabbing, You are a very professional blogger. I have joined your feed and stay up for in search of more of your great post. Also, I’ve shared your web site in my social networks!

Some genuinely wonderful information, Sword lily I observed this. “A poem is never finished, only abandoned.” by Paul Valery.

I got what you intend, thanks for posting.Woh I am delighted to find this website through google. “The test and use of a man’s education is that he finds pleasure in the exercise of his mind.” by Carl Barzun.

I think this is one of the most significant info for me. And i’m glad reading your article. But wanna remark on few general things, The site style is great, the articles is really nice : D. Good job, cheers

I’ve been surfing on-line more than 3 hours as of late, yet I by no means found any attention-grabbing article like yours. It’s lovely value enough for me. In my opinion, if all site owners and bloggers made excellent content as you probably did, the internet might be a lot more useful than ever before. “No nation was ever ruined by trade.” by Benjamin Franklin.

F*ckin’ tremendous things here. I am very glad to see your article. Thanks a lot and i am looking forward to contact you. Will you kindly drop me a e-mail?

Have you ever considered writing an ebook or guest authoring on other websites? I have a blog centered on the same topics you discuss and would love to have you share some stories/information. I know my audience would enjoy your work. If you are even remotely interested, feel free to send me an e mail.

Excellent site. Lots of useful info here. I am sending it to some friends ans also sharing in delicious. And naturally, thanks for your sweat!

whoah this weblog is great i love reading your articles. Stay up the good work! You realize, many individuals are hunting around for this information, you could aid them greatly.

สล็อตออนไลน์เว็บตรง ไม่มีขั้นต่ำ เว็บเกมสล็อตออนไลน์ใหม่ล่าสุด ที่กำลังได้รับความนิยมในกล่มนักการพนันอย่างมากในปัจจุบัน เว็บไซต์SLOTเป็นที่นิยม 2022 ของพวกเราเปิดให้บริการ เกมสล็อต ส่งตรงจากต่างประเทศ สล็อตเว็บตรง ฝากถอนไม่มีขั้นต่ำ ช่วยให้ท่านได้สัมผัสประสบการณ์ เว็บเดิมพันSLOT มีใบรับรอง พร้อมได้รับมาตราฐาสากลของโลกเพื่อให้ทุกคนได้ เว็บไซต์slotที่มีคุณภาพที่สุด slot online ฟรีเครดิต นักเดิมพันสามารถเล่นในระบบ สล็อตทดลองเล่น

ได้ง่ายๆเพียงแค่ทุกๆท่านสมัคร USER กับทาง เว็บตรงสล็อต

ไม่มีขั้นต่ำ จะทำให้ทุกท่านนั้นได้

SLOTเครดิตฟรีซึ่งสามารถเล่นเกม SLOT ONLINEที่อยู่ใน เว็บเดิมพันของเราได้ทุกเกมโดยทุกๆคนไม่ต้องทำการฝากเงินเข้าสู่ระบบของพวกเราก่อนเลยสามารถเล่น สล็อตเว็บตรงไม่ผ่านเอเย่นต์ ไม่มีขั้นต่ำ ของพวกเราได้ทุกเกมเช่นเกม SLOTมาใหม่หรือเกม slot ยอดนิยม เหมาะกับนักเดิมพันทุกวัยที่ต้องการเพิ่มโอกาสในการชนะ เกมเกมสล็อต

โดยเรียนรู้เกมได้ง่ายๆหาเกมที่ถูกใจแล้วเล่นจนเข้าใจใจฟิเจอร์ รู้เรื่องการแตกของ เกมslot นั้นๆเรียนรู้เพื่อวางแผนเล่นให้กับเงินทุนของตน

โอกาสชนะได้แจ็คพ็อตอยู่ไม่ไกล slot online เว็บตรง ฝากถอนไม่มีขั้นต่ำ ของพวกเรามาพร้อม บริการ ฝากถอนไม่มีขั้นต่ำ บนโทรศัพท์มือถือที่เล่นได้เงินจริง ฝากถอนออโต้ถอนเงินไม่มีขั้นต่ำ ฝากเงินไม่มีขั้นต่ำ

บริการและระบบ เพื่ออำนวยความสะดวกให้ผู้เล่นมากที่สุด โดยสามารถดำเนินธุรกรรมได้ด้วยตัวเอง

ไม่ต้องทักหาผู้ดูแลอีกต่อไป ไม่ต้องส่งสลิป ทุกคนสามารถดำเนินการได้ด้วยตัวเอง ไม่เสียค่าบริการ ฝากถอนออโต้ฝากถอน ไม่มีขั้นต่ำ เบท1บาทก็สามารถเล่น slot ของเราได้ทุกเกมเหมาะสำหรับมือใหม่ที่กำลังหาประสบการณ์เล่น เว็บตรงสล็อต ไม่มีขั้นต่ำ รวมทั้งผู้เล่นที่มีทุนน้อย ตอบโจทย์แน่นอน

เมื่อท่านเข้ามาเป็นสมาชิกกับเรา ทุกท่านจะได้รับสิทธิประโยชน์มากมายได้แก่โปรโมชั่นที่พวกเราได้คัดสรรค์มาเพื่อสมาชิกของเราได้เล่น สล็อตออนไลน์เว็บตรง

ไม่มีขั้นต่ำ ได้มันเพลิดเพลินสนุกสนานกับแจ็คพอตเยอะขึ้น พวกเราได้รวบรวมเกม เกมสล็อตออนไลน์ แตกง่าย มารวมที่ เว็บเกมสล็อตออนไลน์ ของเรา

ที่เดียวแล้วมากกว่า 15 ค่ายสล็อตอื่นๆอีกหลายค่ายจากค่ายสล็อตออนไลน์อื่นๆอีกหลายค่ายเกมสล็อตออนไลน์ดังได้แก่ slot pg เว็บหลัก , สล็อตXO แตกง่าย , ทางเข้าเล่น

joker123 , SUPERSLOT แตกบ่อย , สล็อต amb เว็บใหญ่ ,

slot pragmatic เว็บหลัก แล้วก็ค่ายสล็อตอื่นๆอีกหลายค่าย

ที่เราได้คัดสรรค์เกม slot กำลังมาแรงจากค่ายดังมาให้ทุกๆท่านแล้ว รวมค่าย SLOT เว็บตรง ฝากถอนไม่มีขั้นต่ำ ใน เว็บSLOT ONLINE เว็บเดียวเปิดให้บริการ

24 ชม. เปิดให้บริการ กับ CASINO ผ่านระบบอินเตอร์เน็ตช่วยให้นักพนัน ไม่ต้องเล่นเกม slot ที่จำเจกับการเล่น slot เว็บตรง ไม่มีขั้นต่ำ อีกต่อไปเรายังเปิดให้ร่วมสนุกกับรูปแบบเกม

SLOT ONLINE มากมายได้แก่ สล็อตออนไลน์,แทงบอล , BACCARAT

ONLINE , ROULETTE , หวยออนไลน์ , blackjack , POKER , เกมยิงปลาออนไลน์ และอีกมากมายที่จะทำให้ ทุกๆคนได้พบกับความสนุกสนานมากยิ่งกว่า 200 คนที่มีประสบการณ์ทำงานมากกว่า 2

ปีที่จะคอยดูแลทุกคนที่เข้ามาเล่น เว็บตรงสล็อตออนไลน์ ฝากถอนไม่มีขั้นต่ำ ของพวกเราหรือนักเดิมพันท่านใดที่เกิดปัญหาอยากปรึกษาก็สามารถทักหาคณะทำงานเราได้ตลอด 24 ชั่วโมง

สล็อตเว็บตรง

I like what you guys are up too. Such clever work and reporting! Keep up the superb works guys I have incorporated you guys to my blogroll. I think it’ll improve the value of my site 🙂

I think this internet site has got some really good information for everyone :D. “Anybody who watches three games of football in a row should be declared brain dead.” by Erma Bombeck.

Fantastic post however , I was wanting to know if you could write a litte more on this topic? I’d be very grateful if you could elaborate a little bit further. Kudos!

I think other website proprietors should take this site as an model, very clean and fantastic user friendly style and design, let alone the content. You are an expert in this topic!

Loving the info on this website , you have done outstanding job on the content.

Hi there! Do you use Twitter? I’d like to follow you if that would be okay. I’m definitely enjoying your blog and look forward to new updates.

Have you ever considered creating an e-book or guest authoring on other blogs? I have a blog based on the same subjects you discuss and would love to have you share some stories/information. I know my subscribers would value your work. If you’re even remotely interested, feel free to shoot me an e mail.

Hi , I do believe this is an excellent blog. I stumbled upon it on Yahoo , i will come back once again. Money and freedom is the best way to change, may you be rich and help other people.

It’s a shame you don’t have a donate button! I’d certainly donate to this brilliant blog! I suppose for now i’ll settle for bookmarking and adding your RSS feed to my Google account. I look forward to fresh updates and will talk about this blog with my Facebook group. Chat soon!

As I website possessor I believe the content matter here is rattling great , appreciate it for your efforts. You should keep it up forever! Best of luck.

You made various good points there. I did a search on the topic and found mainly persons will consent with your blog.

Hiya, I am really glad I’ve found this information. Nowadays bloggers publish only about gossips and internet and this is actually annoying. A good blog with exciting content, this is what I need. Thanks for keeping this website, I’ll be visiting it. Do you do newsletters? Can’t find it.

Respect to website author, some good entropy.

Really good visual appeal on this site, I’d value it 10 10.

Really nice pattern and excellent content, very little else we need : D.

Test IPTV.RO triɑl ѕubѕcrіption,they һave ɑll you need

Gut schreiben, Ich bin normaler Besucher der eigenen Blog, halte den nett Betrieb aufrecht, und Es wird für eine lange Zeit ein regelmäßiger Besucher sein.

Merci pour les grands post. Je suis recherche ce chose pour un jour . Les produits et détails que vous précisez, je n’étais pas au courant . Je serai suivant votre blog maintenant et J’espère vous pouvez beaucoup plus vues et idées.

I have been absent for a while, but now I remember why I used to love this website. Thank you, I will try and check back more frequently. How frequently you update your site?

I not to mention my buddies have been studying the best pointers found on the blog and then immediately I had an awful feeling I never expressed respect to the web site owner for those secrets. These men appeared to be so happy to see them and have in effect definitely been enjoying these things. Thank you for being so thoughtful and also for figuring out this form of extraordinary subject areas most people are really wanting to be informed on. My very own honest regret for not expressing appreciation to sooner.

Magnificent goods from you, man. I’ve understand your stuff previous to and you are just extremely fantastic. I actually like what you’ve acquired here, certainly like what you are stating and the way in which you say it. You make it enjoyable and you still take care of to keep it wise. I can’t wait to read far more from you. This is really a tremendous website.

I like the valuable info you provide for your articles. I’ll bookmark your blog and check once more here frequently. I’m relatively sure I’ll be informed plenty of new stuff proper right here! Best of luck for the next!

It’s really a nice and helpful piece of info. I am glad that you simply shared this useful information with us. Please stay us informed like this. Thanks for sharing.

F*ckin’ awesome things here. I’m very glad to see your post. Thanks a lot and i am looking forward to contact you. Will you kindly drop me a e-mail?

Good day! I know this is kinda off topic nevertheless I’d figured I’d ask. Would you be interested in exchanging links or maybe guest authoring a blog post or vice-versa? My website covers a lot of the same topics as yours and I feel we could greatly benefit from each other. If you might be interested feel free to send me an email. I look forward to hearing from you! Excellent blog by the way!

Have you ever thought about adding a little bit more than just your articles? I mean, what you say is important and everything. Nevertheless imagine if you added some great graphics or videos to give your posts more, “pop”! Your content is excellent but with pics and video clips, this website could certainly be one of the most beneficial in its field. Terrific blog!

Fantastic website. Lots of helpful info here. I’m sending it to some pals ans also sharing in delicious. And obviously, thank you to your effort!

This really answered my downside, thank you!

I’m not sure exactly why but this site is loading extremely slow for me. Is anyone else having this issue or is it a issue on my end? I’ll check back later on and see if the problem still exists.

Hmm it looks like your website ate my first comment (it was super long) so I guess I’ll just sum it up what I wrote and say, I’m thoroughly enjoying your blog. I as well am an aspiring blog blogger but I’m still new to everything. Do you have any helpful hints for novice blog writers? I’d genuinely appreciate it.

I like this web site very much, Its a really nice billet to read and receive info . “The mark of a good action is that it appears inevitable in retrospect.” by Robert Louis Stephenson.

I like this blog very much, Its a really nice position to read and incur info . “Young men think old men are fools but old men know young men are fools.” by George Chapman.

I’d have to examine with you here. Which is not one thing I often do! I take pleasure in studying a post that may make folks think. Additionally, thanks for allowing me to remark!

Useful information. Fortunate me I discovered your web site by accident, and I am stunned why this twist of fate did not came about in advance! I bookmarked it.

Hi would you mind sharing which blog platform you’re working with? I’m going to start my own blog in the near future but I’m having a hard time making a decision between BlogEngine/Wordpress/B2evolution and Drupal. The reason I ask is because your layout seems different then most blogs and I’m looking for something unique. P.S Apologies for being off-topic but I had to ask!

Would love to forever get updated outstanding blog! .

I¦ve learn several just right stuff here. Certainly worth bookmarking for revisiting. I wonder how a lot effort you put to create the sort of wonderful informative site.

When I initially commented I clicked the -Notify me when new comments are added- checkbox and now every time a comment is added I get four emails with the identical comment. Is there any means you can take away me from that service? Thanks!

Some really nice and utilitarian information on this internet site, also I think the pattern has good features.

I’ve been exploring for a little bit for any high-quality articles or blog posts on this sort of area . Exploring in Yahoo I at last stumbled upon this web site. Reading this info So i am happy to convey that I’ve an incredibly good uncanny feeling I discovered exactly what I needed. I most certainly will make certain to don’t forget this website and give it a glance on a constant basis.

Right now it looks like Movable Type is the top blogging platform out there right now. (from what I’ve read) Is that what you’re using on your blog?

Howdy! Do you know if they make any plugins to safeguard against hackers? I’m kinda paranoid about losing everything I’ve worked hard on. Any recommendations?

Thank you for any other informative web site. The place else could I am getting that kind of information written in such an ideal manner? I have a challenge that I’m simply now operating on, and I have been at the look out for such information.

you have a great blog here! would you like to make some invite posts on my blog?

I was looking at some of your content on this website and I conceive this web site is rattling informative ! Retain posting.

Youre so cool! I dont suppose Ive learn anything like this before. So good to find anyone with some unique ideas on this subject. realy thanks for starting this up. this web site is one thing that is wanted on the web, somebody with a bit originality. useful job for bringing something new to the internet!

Wow! This can be one particular of the most helpful blogs We’ve ever arrive across on this subject. Actually Great. I am also a specialist in this topic so I can understand your hard work.

I am no longer sure where you’re getting your information, but great topic. I must spend some time studying more or working out more. Thank you for great information I used to be looking for this info for my mission.

Some really terrific work on behalf of the owner of this site, utterly outstanding subject matter.

Wow! This can be one particular of the most beneficial blogs We’ve ever arrive across on this subject. Basically Great. I’m also a specialist in this topic so I can understand your hard work.

Heya! I just wanted to ask if you ever have any problems with hackers? My last blog (wordpress) was hacked and I ended up losing months of hard work due to no data backup. Do you have any solutions to protect against hackers?

My programmer is trying to persuade me to move to .net from PHP. I have always disliked the idea because of the costs. But he’s tryiong none the less. I’ve been using Movable-type on numerous websites for about a year and am concerned about switching to another platform. I have heard great things about blogengine.net. Is there a way I can import all my wordpress posts into it? Any help would be greatly appreciated!

We’re a group of volunteers and starting a new scheme in our community. Your website provided us with valuable info to work on. You’ve done an impressive job and our whole community will be grateful to you.

I’m really loving the theme/design of your weblog. Do you ever run into any web browser compatibility problems? A handful of my blog readers have complained about my website not working correctly in Explorer but looks great in Safari. Do you have any suggestions to help fix this problem?

Hi, just required you to know I he added your site to my Google bookmarks due to your layout. But seriously, I believe your internet site has 1 in the freshest theme I??ve came across. It extremely helps make reading your blog significantly easier.

Enjoyed looking at this, very good stuff, thankyou.

Thanks for sharing superb informations. Your web site is very cool. I’m impressed by the details that you have on this website. It reveals how nicely you perceive this subject. Bookmarked this website page, will come back for extra articles. You, my pal, ROCK! I found simply the info I already searched everywhere and just could not come across. What a perfect site.